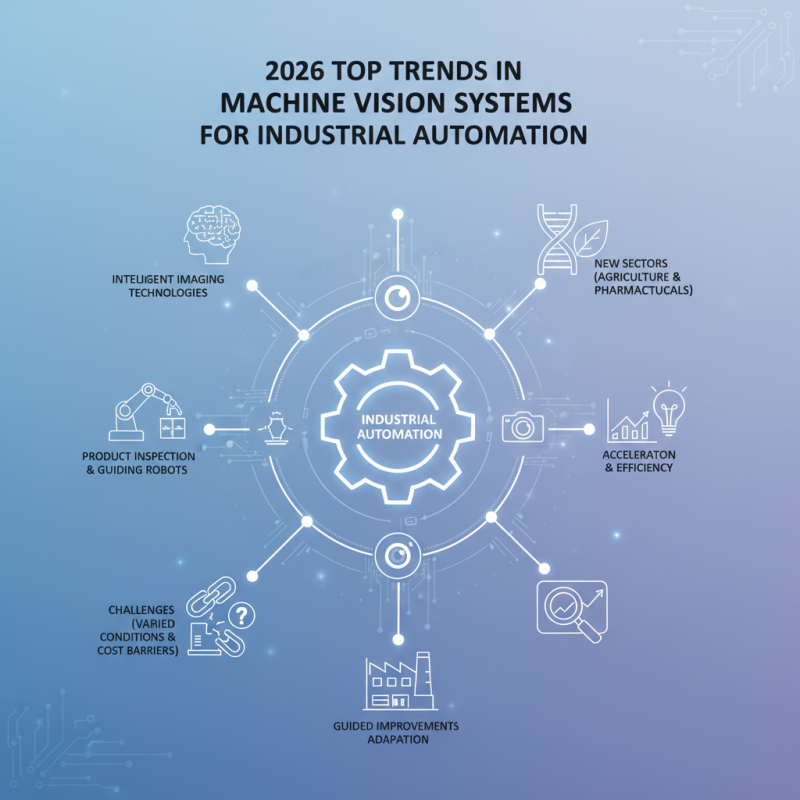

2026 Top Trends in Machine Vision Systems for Industrial Automation?

As industries evolve, the significance of the machine vision system grows. In 2026, many trends will shape its future. These advancements will enhance productivity and precision in automation processes.

Machine vision systems integrate intelligent imaging technologies. They help in inspecting products, guiding robots, and ensuring quality control. The increasing need for efficiency drives this trend. Companies are exploring new sectors for deployment, such as agriculture and pharmaceuticals. With rising demand, innovation will accelerate.

However, challenges persist. Not all systems work seamlessly under varied conditions. Costs can also be a barrier for smaller businesses. Understanding these limitations is crucial for effective implementation. As we look to the future, recognizing imperfections will guide improvements in machine vision technology.

Emerging Technologies in Machine Vision Systems for 2026

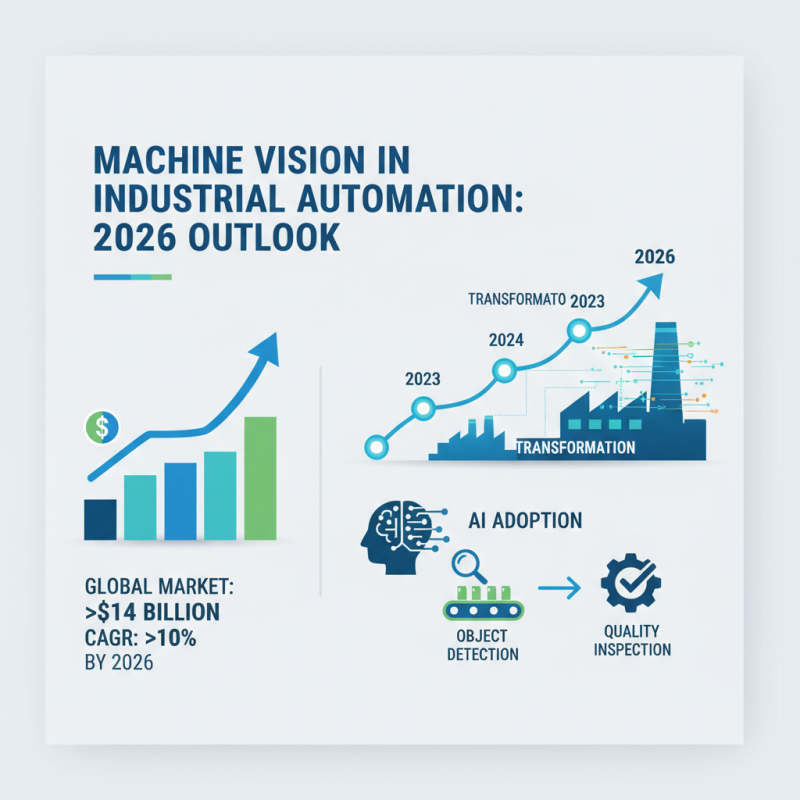

As we approach 2026, the landscape of machine vision systems in industrial automation is undergoing significant transformation. Emerging technologies are reshaping how manufacturers operate. According to a recent industry report, the global market for machine vision systems is projected to surpass $14 billion by 2026, with a compound annual growth rate of over 10%. This growth reflects the increasing adoption of artificial intelligence in vision systems, enhancing object detection and quality inspection processes.

One notable trend is the integration of deep learning algorithms. These systems can learn and adapt, improving their accuracy over time. Companies are investing heavily in AI to automate visual inspections and reduce errors. Yet, reliance on these technologies raises questions about potential job impacts and the need for human oversight. The balance between automation and labor remains a critical discussion point.

Another trend is the deployment of 3D vision systems. These systems provide depth perception and increase accuracy in complex environments. This technology finds applications in robotics and assembly lines. However, implementing 3D vision comes with its challenges, such as higher costs and the need for specialized skills. Organizations must carefully weigh the benefits against the hurdles of change and adaptation.

Key Applications of Machine Vision in Industrial Automation

Machine vision systems are transforming industrial automation. They enhance quality control and boost efficiency. According to recent reports, the global machine vision market is expected to reach $16 billion by 2025. This growth is driven by rising demands in sectors like manufacturing, automotive, and electronics.

One key application of machine vision is in defect detection. Cameras capture images of products and software analyzes them for imperfections. This fast and accurate process reduces waste and ensures high standards. Another application is in robotic guidance. Vision systems help robots navigate complex environments. This is vital for automated assembly lines. However, reliance on these technologies could lead to challenges, such as false positives in detection.

Data from industry experts state that about 30% of companies still face integration issues with machine vision systems. Many find it hard to adapt existing processes to new technology. This highlights the need for better training and clearer implementation strategies. Despite these challenges, the potential benefits of machine vision systems remain significant.

Advancements in AI and Deep Learning for Vision Systems

Machine vision systems are evolving rapidly, particularly with advancements in AI and deep learning. These technologies enhance the ability of machines to interpret visual data. They enable real-time analysis, offering better accuracy in detecting defects on production lines. For instance, components can be analyzed for minute imperfections. However, the effectiveness of these systems can vary. They sometimes struggle with obscure items or varying lighting conditions.

Deep learning algorithms are increasingly being integrated into vision systems. This allows for improved image recognition capabilities, making them smarter over time. They learn from vast datasets, which can be both a strength and a limitation. If the training data is biased or insufficient, the system’s performance can falter. Additionally, implementing these sophisticated systems may require specialized knowledge, which can be a barrier in some industrial environments.

Yet, the potential for efficiency and cost savings remains substantial. As machine vision becomes more precise, the accuracy of quality control improves. This can lead to reduced waste and higher productivity. However, companies must reassess their processes to fully leverage these advancements. They need to ensure proper implementation and continuously monitor system performance. The road ahead may be challenging, but the promise of truly intelligent vision systems is enticing.

2026 Top Trends in Machine Vision Systems for Industrial Automation

This chart illustrates the anticipated growth and adoption of various AI and Deep Learning advancements in machine vision systems within industrial automation by 2026. The data represents estimated percentage increases in adoption rates across different applications.

Integration of Multi-Sensor Systems in Manufacturing Processes

The integration of multi-sensor systems is transforming manufacturing processes. This approach combines data from cameras, LIDAR, and other sensors. The result is improved accuracy and efficiency. For example, manufacturers using multi-sensor setups report a 30% reduction in defects. Yet, challenges remain. Not all manufacturers are equipped to handle complex data streams.

Tips: Invest in training staff. Understanding multi-sensor technology is vital. Regular workshops help keep skills sharp.

Data fusion is essential in making sense of sensor information. A 2021 report highlighted that over 70% of facilities see enhanced productivity with multi-sensor integration. However, system interoperability can be an issue. Different sensor types may not communicate effectively without proper integration. It’s crucial to address these concerns early on.

Tips: Start with a pilot project. This allows for testing and adjustments without overwhelming the system. Gradual implementation offers real-world data for evaluation.

Future Challenges and Opportunities in Machine Vision Adoption

The future of machine vision in industrial automation presents both challenges and opportunities. As technology evolves rapidly, companies must adapt. One challenge is the integration of advanced algorithms into existing systems. Misalignment can lead to errors and inefficiencies. The solution lies in a thoughtful approach to implementation.

Tips: Invest in staff training. Understanding new systems is essential. A well-trained workforce can leverage machine vision effectively. Continuous learning helps address gaps in knowledge.

Another challenge is data processing. With increasing volumes of information, real-time analysis becomes crucial. Delays can diminish productivity and affect decision-making. Companies need robust strategies for handling data. Set clear protocols for data flow. It’s vital to ensure accuracy, as mistakes can have costly consequences.

Tips: Regularly review processes. Reflection can highlight areas for improvement. Adaptation is key in a fast-paced environment. Embracing change may lead to unexpected benefits.

Related Posts

-

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

2026 Best Solenoid Valve Distributors to Consider?

-

How to Choose the Right Pneumatic Solenoid Valve for Your Application?

-

Top 10 Automation Solutions Transforming Business Efficiency Today?

-

What Are Pneumatic Operated Valves and How Do They Work?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries