Understanding the Science Behind Humphrey Air Valves in Modern Applications

In today's rapidly advancing industrial landscape, the significance of precision control mechanisms such as the Humphrey air valve cannot be overstated.

According to a ReportLinker analysis, the global pneumatic valves market is projected to reach approximately $6.9 billion by 2026, driven by the increasing demand for automation and efficiency in various sectors, including manufacturing and robotics.

Humphrey air valves stand at the forefront of this evolution, offering unprecedented reliability and functionality in controlling airflow in pneumatic systems. These valves are integral components that not only enhance operational efficacy but also contribute to energy savings and reduced environmental impact.

As businesses increasingly shift towards smart and sustainable solutions, understanding the science behind Humphrey air valves emerges as a critical factor for success in modern applications.

Humphrey air valves stand at the forefront of this evolution, offering unprecedented reliability and functionality in controlling airflow in pneumatic systems. These valves are integral components that not only enhance operational efficacy but also contribute to energy savings and reduced environmental impact.

As businesses increasingly shift towards smart and sustainable solutions, understanding the science behind Humphrey air valves emerges as a critical factor for success in modern applications.

The Evolution of Humphrey Air Valves in Industrial Applications

The evolution of Humphrey Air Valves has been significant in enhancing efficiency and reliability in industrial applications. Initially developed for basic pneumatic systems, these valves have transformed to accommodate the increasing demands of modern automation. According to a report from the International Journal of Pneumatics, the global market for pneumatic valves, including those developed by Humphrey, is expected to reach $8 billion by 2025, with a compound annual growth rate (CAGR) of 5.5%. This growth underscores the critical role of advanced air valve technology in optimizing performance across various sectors, including manufacturing, automotive, and packaging.

Recent advancements have seen Humphrey Air Valves incorporate smart technologies, allowing for real-time monitoring and control within industrial operations. Data from the Industrial Automation Association indicates that smart valve technologies can reduce energy consumption by up to 30%, providing not only operational efficiency but also sustainability in manufacturing processes. These innovations offer improved response times and enhanced precision, further driving adoption in environments where accuracy is paramount. As industries continue to seek automation solutions, the evolution of Humphrey Air Valves plays a pivotal role in shaping the future of pneumatic systems.

Key Performance Metrics: Efficiency and Reliability of Air Valves

Air valves play a crucial role in various modern applications, with Humphrey air valves standing out due to their exceptional performance metrics. Efficiency in air valves is determined by their ability to control airflow dynamically, ensuring optimal energy use in pneumatic systems. With advancements in materials and design, Humphrey air valves achieve higher flow rates while minimizing pressure loss, significantly enhancing system performance. This efficiency translates directly into energy savings, making them a preferred choice in sectors ranging from manufacturing to robotics.

Reliability is another key metric where Humphrey air valves excel. Built to endure rigorous operational demands, these valves undergo extensive testing to ensure they function accurately under various conditions. Their robust design minimizes the likelihood of failure, securing consistent performance over time. This reliability is vital in critical applications where failure could lead to safety hazards or operational downtime. With these combined attributes of efficiency and reliability, Humphrey air valves effectively meet the stringent demands of contemporary industrial applications, showcasing their integral role in advancing technology across sectors.

Understanding the Efficiency and Reliability of Air Valves

This chart illustrates the efficiency and reliability metrics of air valves in various applications, highlighting their performance in terms of opening time and failure rate over a period of use.

Comparative Analysis: Humphrey Air Valves vs. Traditional Pneumatic Solutions

In recent years, the adoption of Humphrey air valves has been on the rise, particularly in applications where precision and efficiency are paramount. A comparative analysis reveals that Humphrey air valves offer significant advantages over traditional pneumatic solutions. According to a report by the International Society for Automation (ISA), systems utilizing Humphrey valves can achieve up to 30% faster response times compared to conventional pneumatic valves, primarily due to their advanced design and control mechanisms. This improvement can lead to enhanced operational efficiency and reduced cycle times in various industrial processes.

Moreover, Humphrey air valves typically exhibit lower maintenance requirements than traditional pneumatic solutions. Research from the Pneumatics Manufacturers Association indicates that conventional valves often face issues such as leakage and wear over time, leading to increased maintenance costs, estimated to be around 20% higher than those associated with Humphrey valves. The durability and reliability of Humphrey valves, which feature robust materials and innovative sealing technologies, contribute to their longer lifespan and lower operational costs, making them a more economical choice in the long run for industries reliant on pneumatic systems.

Innovative Applications of Humphrey Air Valves in Automation Technology

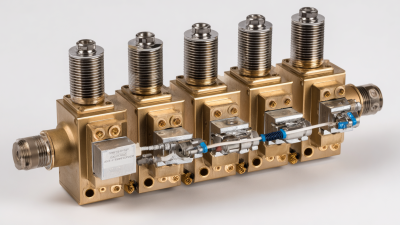

Humphrey air valves have emerged as a critical component in the realm of automation technology, showcasing their versatility across various applications. These valves facilitate precise control over pneumatic systems, allowing for enhanced efficiency and reliability in automated processes. By enabling rapid response times and smooth operation, Humphrey air valves are essential for industries ranging from manufacturing to robotics, where precision and speed are paramount.

In innovative automation systems, the integration of Humphrey air valves leads to significant improvements in workflow efficiency. For example, in pick-and-place applications, these valves allow for swift actuation and retraction of robotic arms, ensuring seamless transitions between tasks. Additionally, their compact design makes them ideal for space-sensitive installations, such as in conveyor systems and assembly lines. As automation technology continues to evolve, the adaptability and reliability of Humphrey air valves play a crucial role in meeting the demands of modern industrial applications.

Future Trends: Integrating Smart Technologies with Air Valve Design

As the demand for efficient air management systems grows in various industries, the integration of smart technologies into the design of air valves has begun to reshape their functionality and application. The trend towards automation and digital solutions is particularly relevant in sectors like automotive and renewable energy, where enhanced performance and reliability are critical. According to a recent industry report, the global smart valve market is projected to reach $8.5 billion by 2025, driven by advancements in IoT and AI technologies. This growth indicates a significant shift toward intelligent systems capable of real-time monitoring and optimization.

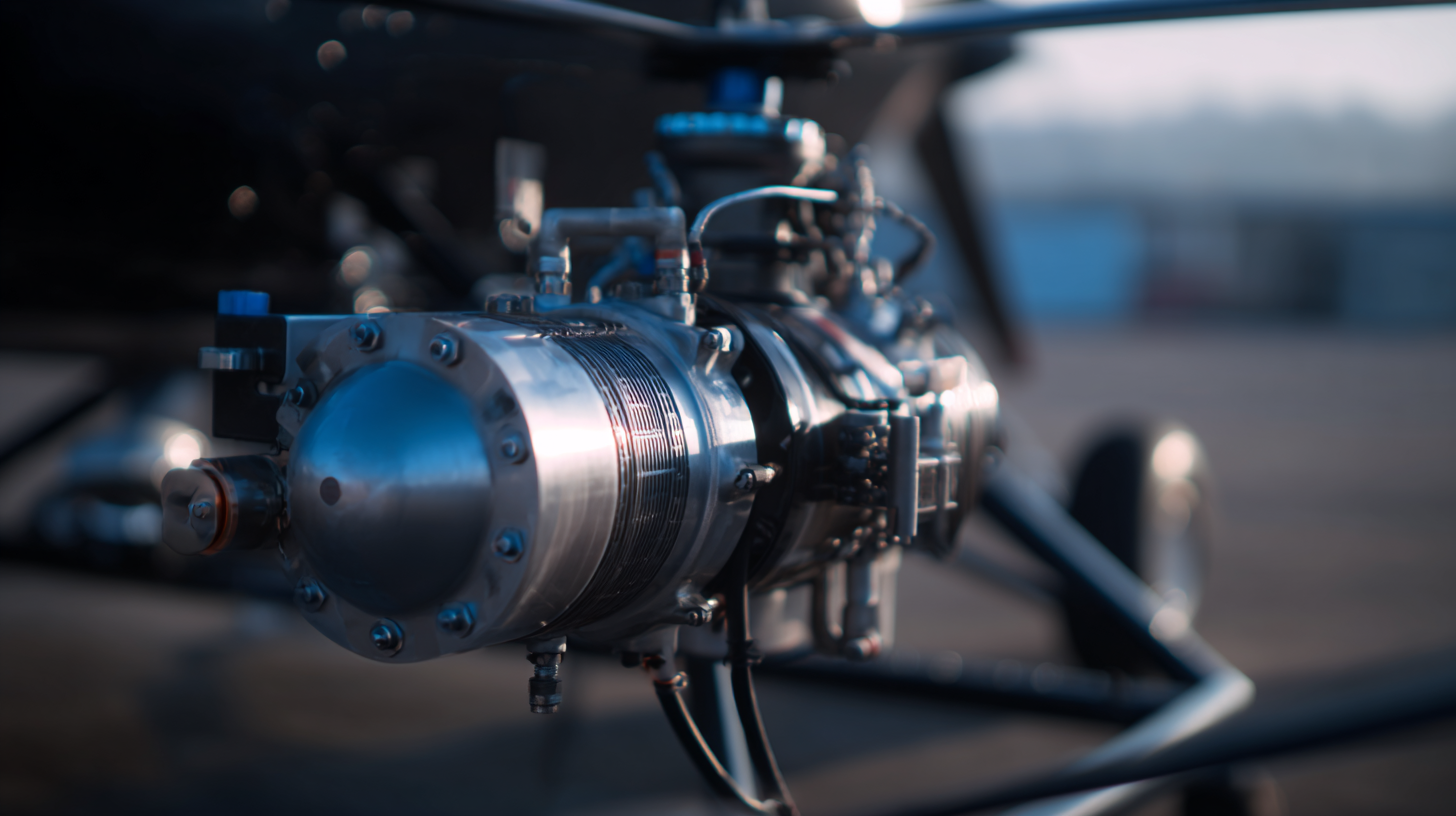

Recent developments in battery management technologies also parallel this trend, highlighting the importance of effective thermal management within power systems. Innovative cooling solutions are essential for maintaining optimal performance in electric vehicles, where air valves play a crucial role in managing temperature variations. With new insights into dynamic control strategies, the integration of air valves with sensor technologies is expected to enhance not only the efficiency of thermal management systems but also overall vehicle performance.

The synergy between air valve technology and smart innovations promises a transformative impact on future design and efficiency standards across various applications.

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries