Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

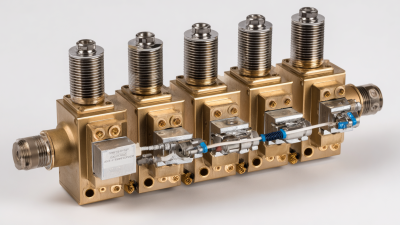

In modern automation systems, the role of pneumatic solenoids has become increasingly pivotal, underpinning the efficiency and functionality of various industrial applications. According to a report by MarketsandMarkets, the global pneumatic components market is projected to reach $16.3 billion by 2025, with pneumatic solenoids playing a crucial part in this growth due to their ability to convert electrical energy into mechanical motion. These devices are essential for controlling the flow of air in pneumatic systems, thereby enhancing the precision and responsiveness of automated processes.

The introduction of advanced technologies and smart automation systems further accentuates the significance of pneumatic solenoids, as industries seek to optimize operations and reduce downtime. As the demand for automation rises, understanding the intricacies of pneumatic solenoids will be vital for engineers and industry professionals striving to leverage their benefits in contemporary manufacturing and process control.

The introduction of advanced technologies and smart automation systems further accentuates the significance of pneumatic solenoids, as industries seek to optimize operations and reduce downtime. As the demand for automation rises, understanding the intricacies of pneumatic solenoids will be vital for engineers and industry professionals striving to leverage their benefits in contemporary manufacturing and process control.

The Critical Function of Pneumatic Solenoids in High-Speed Automation Processes

Pneumatic solenoids play a crucial role in high-speed automation processes, serving as the vital components that control the flow of compressed air, which is essential for the operation of various machinery. According to a report by MarketsandMarkets, the global pneumatic solenoid market is expected to reach USD 2.43 billion by 2025, reflecting a CAGR of 5.2% from 2020. This growth underscores the increasing reliance on pneumatic systems in manufacturing and assembly lines, where speed and precision are paramount. Solenoids enable rapid actuation, allowing manufacturers to automate processes that were previously manual, leading to enhanced efficiency and reduced cycle times.

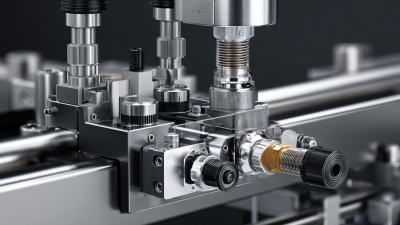

When integrating pneumatic solenoids into your automation system, it is crucial to ensure compatibility with your existing machinery. One key tip is to always consult equipment specifications and perform thorough testing during the installation phase. Additionally, regular maintenance can prevent downtime caused by solenoid failures. A 2021 survey from the International Society of Automation indicates that 27% of unplanned downtime in manufacturing is attributed to system component failures, including solenoids. Adopting preventive maintenance schedules can help mitigate these risks and maintain operational flow.

Moreover, the selection of the appropriate solenoid types—such as single-acting or double-acting—based on the specific application requirements is essential. For high-speed operations, opting for solenoids with rapid response times can significantly improve throughput. Implementing easy-to-use diagnostics systems can also provide real-time insights into solenoid performance, ensuring optimal operations while minimizing potential delays in production.

Key Advantages of Pneumatic Solenoids Over Electric Actuators in Manufacturing

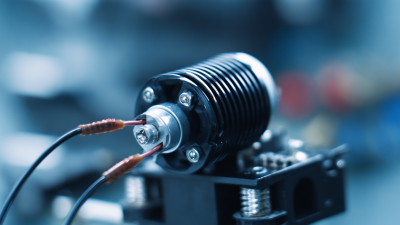

Pneumatic solenoids play a critical role in modern automation systems, particularly in manufacturing environments where speed, efficiency, and reliability are paramount. One of the key advantages of pneumatic solenoids over electric actuators is their rapid response time. Pneumatic systems can achieve full activation almost instantaneously, allowing for quick adjustments and minimizing downtime in production lines. This attribute is especially beneficial in applications where precision and timing are crucial, such as in assembly processes that require synchronizing movements of multiple components.

Another significant advantage is the inherent safety features of pneumatic solenoids. Unlike electric actuators, which can pose fire hazards in certain environments, pneumatic systems operate with compressed air and often produce less heat. This makes them ideal for use in explosive or high-temperature settings. Additionally, pneumatic systems can maintain performance in challenging conditions, including dirty or wet environments, where electric actuators might fail. The robustness of pneumatic solenoids, combined with their efficiency and speed, positions them as a preferable choice for many industrial applications, enhancing productivity while ensuring worker safety.

Industry Trends: Increasing Adoption of Pneumatic Solenoids in Robotic Systems

In recent years, the automation industry has witnessed a significant trend toward the increased adoption of pneumatic solenoids in robotic systems. As manufacturers strive for enhanced efficiency and precision, pneumatic solenoids are proving to be essential components that drive the functionality of various automated processes. Their ability to precisely control airflow and pressure allows robotic systems to execute tasks with remarkable speed and accuracy, making them indispensable in industries ranging from manufacturing to packaging.

Tip: When integrating pneumatic solenoids into robotic systems, it's crucial to carefully assess the specifications of the solenoids to ensure compatibility with the system's requirements. Factors such as voltage ratings, switching times, and pressure handling capacities should all be considered to optimize performance and prevent operational failures.

The rising trend of using pneumatic solenoids is also reflected in advancements in technology, resulting in more compact and efficient designs. These innovations enable systems to become smaller and more energy-efficient, which is a major consideration in modern automation. As robotic applications continue to expand, the demand for versatile and reliable pneumatic solenoids will likely grow, facilitating automation solutions that are both cost-effective and high-performing.

Tip: Regular maintenance and monitoring of pneumatic solenoids can prevent unexpected downtimes and maintain operational efficiency. Implementing a maintenance schedule that includes checking for leaks and ensuring proper lubrication can significantly prolong the lifespan of these components in robotic systems.

The Impact of Pneumatic Solenoids on Energy Efficiency and Cost Reduction in Automation

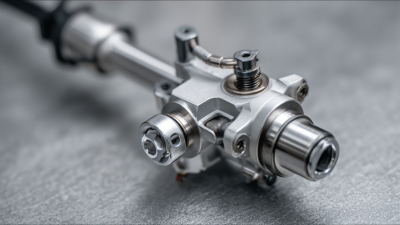

Pneumatic solenoids play a critical role in enhancing energy efficiency and driving cost reduction in modern automation systems. These devices are integral in controlling airflow and regulating pressure within pneumatic systems, allowing for precise operation of machinery. By utilizing quick-response solenoids, businesses can achieve faster cycle times, which directly translates to improved productivity. This efficiency results in lower energy consumption, as machines spend less time idling and more time actively performing tasks.

Furthermore, the implementation of pneumatic solenoids contributes to significant cost savings over time. Enhanced energy efficiency leads to reduced utility bills, while also minimizing wear and tear on equipment. This longevity reduces maintenance expenses and downtime for repairs. Additionally, the ability to precisely control actuators in various applications ensures that resources are used optimally, thus preventing waste. Overall, pneumatic solenoids not only bolster the performance of automation systems but also serve as a key factor in promoting sustainability and economic viability in industrial operations.

Impact of Pneumatic Solenoids on Energy Efficiency and Cost Reduction in Automation

Case Studies: Successful Implementation of Pneumatic Solenoids in Various Industries

Pneumatic solenoids have become pivotal in optimizing automation processes across various industries. In the beverage sector, for instance, innovative applications of pneumatic solenoids have led to significant improvements in operational efficiency and material usage. A notable example is a major mineral water producer that successfully implemented pneumatic solenoids in their case gluing and sealing processes. By integrating these systems, they achieved a remarkable 55% reduction in adhesive consumption, showcasing the potential of solenoid technology to drive sustainability while maintaining product integrity.

Such advancements highlight the versatility and effectiveness of pneumatic solenoids in modern manufacturing environments. In addition to minimizing waste, these systems enable precise control over critical functions, enhancing production speed and consistency. The case of the beverage producer reflects a broader trend where industries are increasingly leveraging automated solutions to refine their operations. As companies continue to seek competitive advantages, the role of pneumatic solenoids is likely to expand, paving the way for further innovations in automation systems across various applications.

Related Posts

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries