Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

In the rapidly evolving landscape of automation and control systems, pneumatic solenoids have emerged as indispensable components across various industries. According to a recent report by MarketsandMarkets, the global solenoid market is projected to reach USD 4.12 billion by 2025, growing at a CAGR of 5.2%. This growth reflects the increasing demand for efficient control mechanisms in sophisticated industrial applications. Pneumatic solenoids, in particular, are recognized for their reliability and effectiveness in handling fluid motion and pressure control, leading to enhanced operational efficiency.

Dr. Lisa Chen, a noted expert in fluid dynamics and automation technologies, emphasizes the transformative potential of pneumatic solenoids in modern applications: "The integration of pneumatic solenoids in industrial automation not only streamlines processes but also significantly reduces energy consumption." As industries strive for greater sustainability and efficiency, the role of pneumatic solenoids is increasingly pivotal. Innovations in this field continue to unlock new possibilities, from advanced manufacturing to critical healthcare apparatus, underscoring the importance of ongoing research and development in pneumatic solenoid technology. Understanding these advancements is crucial for industry professionals aiming to leverage the full potential of pneumatic solenoids in their operations.

Understanding the Fundamentals of Pneumatic Solenoids: How They Work and Their Mechanisms

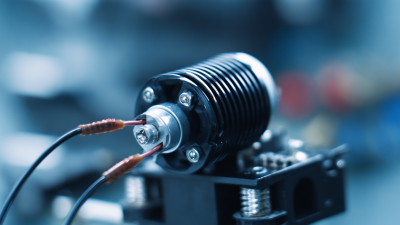

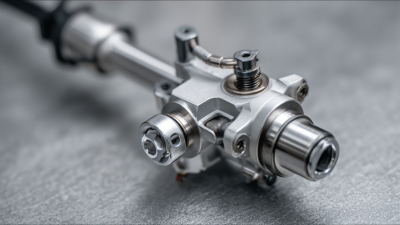

Pneumatic solenoids are essential components in various applications due to their ability to control the flow of pressurized air with precision. Unlike traditional electronic actuators, these devices harness pneumatic pressure to perform tasks, making them invaluable in environments where electronics are impractical. A notable example is a four-legged soft robot that operates solely on pressurized air, demonstrating the versatility of pneumatic systems. According to recent industry studies, the demand for pneumatic actuators is projected to grow at a compound annual growth rate of 5.2% from 2021 to 2026, driven by innovations in automation and robotics.

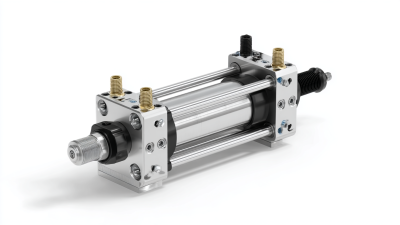

Understanding how pneumatic solenoids work reveals their critical role in air brake systems and fluid control applications. For instance, double-acting pneumatic valve actuators are integral in various industries, offering precise control over airflow and fluid dynamics. In air brake systems for trucks, effective maintenance hinges on understanding the three basic components, which include the compressor, reservoir, and brake chambers, all of which utilize pneumatic principles. Research indicates that optimized pneumatic systems can enhance efficiency and safety in industrial operations, showcasing the importance of mastering solenoid mechanisms in real-world applications.

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

| Application | Description | Innovation | Advantages |

|---|---|---|---|

| Automated Valves | Used to control the flow of fluids in piping systems. | Integration of smart sensors for real-time flow monitoring. | Increased efficiency and reduced waste. |

| Packaging Machinery | Controls pack sealing and filling operations. | Enhanced speed and precision mechanisms. | Higher throughput and lower operating costs. |

| Robotic Arms | Used for movement and control of robotic joints. | Development of multi-axis solenoids for complex maneuvers. | Increases flexibility and performance in automation. |

| Medical Devices | Controls mechanisms in devices like syringe pumps. | Innovative designs for compact and silent operation. | Improved patient comfort and usability. |

Exploring Key Industries: Where Pneumatic Solenoids Are Making an Impact

Pneumatic solenoids are increasingly becoming pivotal in various industries due to their efficiency and reliability in controlling fluid power systems. In the automotive sector, for example, pneumatic solenoids play a crucial role in automated assembly lines, where they facilitate the precision needed for tasks such as paint application and component positioning. According to a recent market research report by Research and Markets, the global pneumatic solenoid market is projected to grow at a CAGR of 5.8% from 2021 to 2028, driven largely by advancements in manufacturing processes and automation technologies.

In the healthcare industry, pneumatic solenoids are utilized in medical devices, particularly in ventilators and surgical equipment, where precise control of gases is essential. The integration of these solenoids ensures accurate dosages and responsiveness, which are critical for patient safety and treatment effectiveness. A report by Grand View Research indicates that the demand for medical equipment incorporating pneumatic technologies is expected to reach USD 15.4 billion by 2027, highlighting the significant impact solenoids have on enhancing operational efficiency and patient outcomes in healthcare settings.

Innovative Applications of Pneumatic Solenoids: Beyond Traditional Uses

Pneumatic solenoids have evolved far beyond their traditional applications in automation and control systems. Today, they are making significant strides in innovative fields such as robotics, medical devices, and even renewable energy systems. For instance, in robotics, pneumatic solenoids are utilized for actuating movements in soft robotics, providing a gentler touch essential for delicate tasks like handling fragile objects. In the medical field, these solenoids can control drug delivery systems, allowing for precise dosages while minimizing waste.

**Tips:** When considering the integration of pneumatic solenoids in your projects, it's crucial to evaluate the pressure requirements and response time needed for optimal performance. Selecting the correct type of solenoid is essential to ensure compatibility with your application.

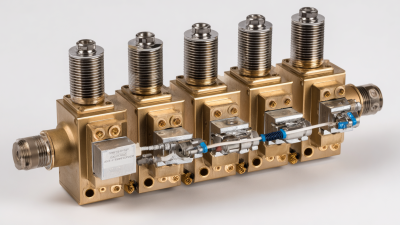

Additionally, advancements in materials and technology have led to the development of more compact and efficient solenoids. Innovations such as smart solenoid valves can be remotely controlled and monitored, paving the way for smarter home automation systems. As industries look for ways to increase efficiency and reduce energy consumption, pneumatic solenoids will undoubtedly play a vital role.

**Tips:** Regular maintenance checks can greatly enhance the lifespan of pneumatic solenoids and improve their efficiency. Consider implementing a routine maintenance schedule to prevent premature wear and to keep your systems running smoothly.

Future Trends: How Innovations Are Shaping the Next Generation of Pneumatic Solenoids

The landscape of pneumatic solenoids is rapidly evolving, driven by innovative technologies that are reshaping their applications across various industries. As manufacturers increasingly focus on automation and smart technology integration, the next generation of pneumatic solenoids is set to deliver enhanced performance, reliability, and energy efficiency. For instance, the introduction of IoT (Internet of Things) capabilities allows these solenoids to be monitored and controlled remotely, leading to improved operational efficiency and troubleshooting.

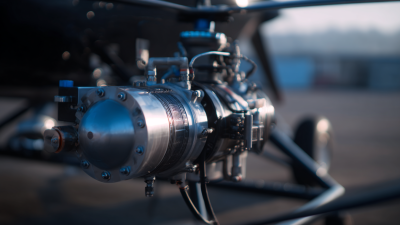

In addition to connectivity advancements, recent developments in materials and design are further propelling the capabilities of pneumatic solenoids. Lightweight and durable materials are being utilized to reduce overall weight while maintaining strength, which is crucial for applications in sectors like aerospace and automotive. Innovations such as advanced sealing technologies also enhance durability and performance, minimizing maintenance needs and extending the lifespan of solenoids. As we look to the future, these trends signal a promising shift towards smarter, more efficient systems that will undoubtedly impact how industries utilize pneumatic solenoids in their operations.

Unlocking the Magic of Pneumatic Solenoids: Applications & Future Trends

Challenges and Solutions: Overcoming Common Issues in Pneumatic Solenoid Applications

Pneumatic solenoids are widely used in various applications ranging from automation to automotive controls. However, their integration is not without challenges. Common issues such as air leaks, coil overheating, and inadequate response times can hinder performance. Addressing these challenges begins with proper maintenance and regular inspections. Ensuring quality control over the components can significantly reduce malfunctions and extend the solenoid's lifespan.

Tips: Regularly check fittings and seals for air leaks, and consider using higher-quality materials to prevent premature wear. Implementing a routine examination schedule can catch problems before they escalate, ensuring smooth operation.

Furthermore, solenoid performance can be optimized through smart design choices. This includes selecting the correct solenoid size and type for your specific application to ensure optimal efficiency. Additionally, enhancing the thermal management of the solenoid by incorporating heat sinks or proper ventilation can prevent overheating issues, which can lead to failure.

Tips: Always refer to manufacturer specifications when selecting solenoids and consider environmental factors that may impact their operation. Using solenoids with integrated cooling systems can also help improve reliability in demanding applications.

Related Posts

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries