Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

The automation industry is rapidly evolving, driven by the need for increased efficiency and reliability in manufacturing processes. Among the essential components that facilitate this transformation are pneumatic solenoid valves, which play a crucial role in controlling the flow of fluids and gases in automated systems. According to a recent report by Market Research Future, the global pneumatic solenoid valve market is expected to reach $5.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is indicative of the increasing reliance on automation technologies across various sectors, including automotive, food and beverage, and pharmaceuticals.

Industry expert Dr. Emily Chen, a leading researcher in automation technologies, emphasizes the significance of pneumatic solenoid valves, stating, "The efficiency of automation systems significantly hinges on the performance of pneumatic solenoid valves; selecting the right valve can enhance operational reliability and reduce maintenance costs." As companies strive to optimize their manufacturing processes, the selection of the appropriate pneumatic solenoid valve becomes a vital decision that can directly affect production efficiency and overall system performance. In this article, we will explore the top five pneumatic solenoid valve choices that cater to enhanced automation efficiency, providing insights into their features, applications, and the reasons behind their popularity in the industry.

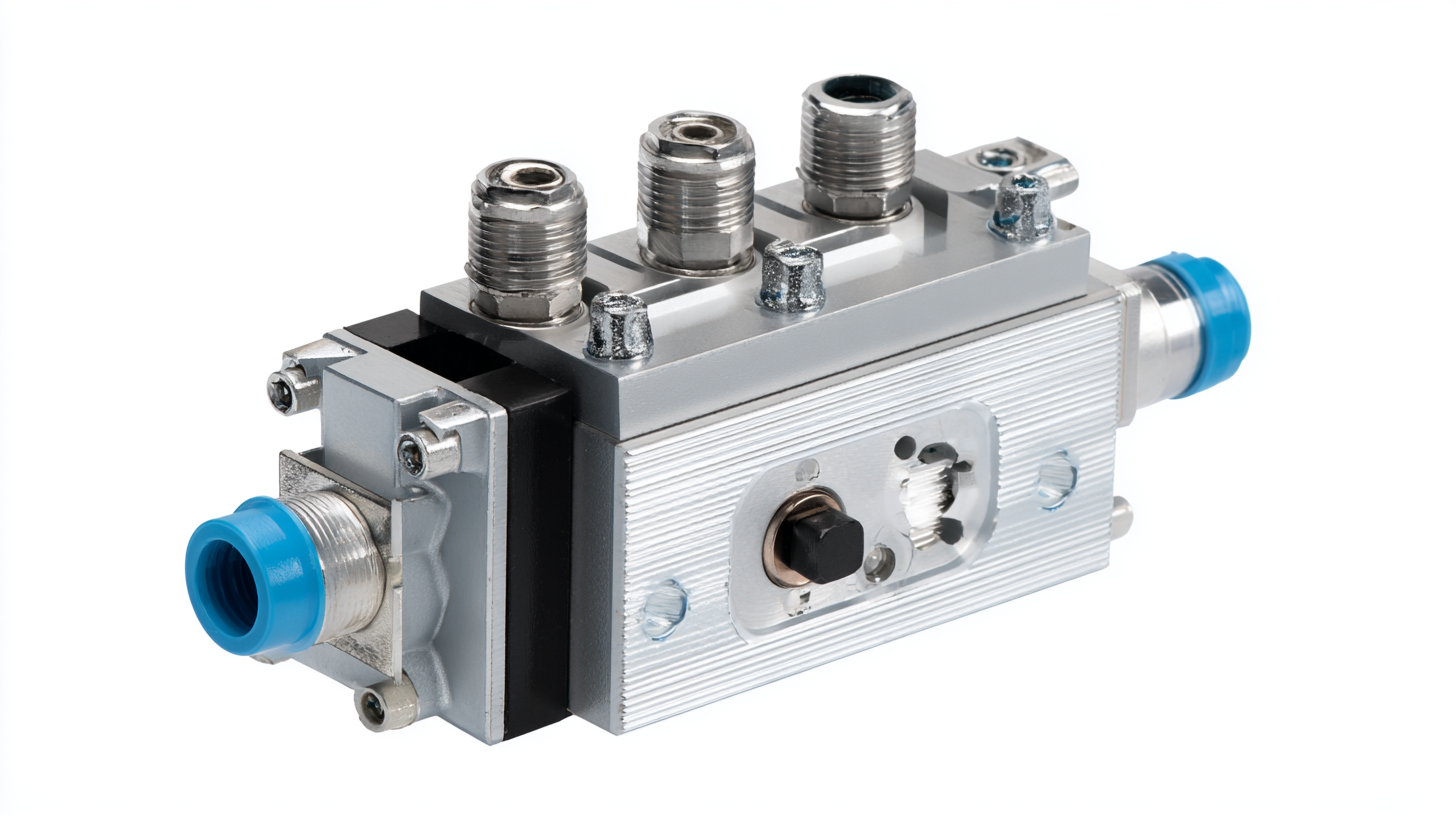

Overview of Pneumatic Solenoid Valve Types and Their Applications

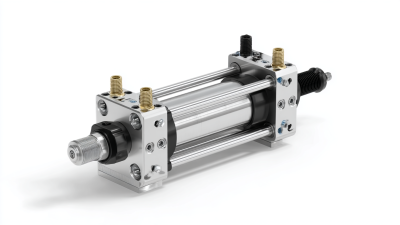

Pneumatic solenoid valves are essential components in automation systems, acting as the control mechanism for airflow and pressure. These valves come in various types, each tailored for specific applications. The most common types include direct-acting, pilot-operated, and 3/2-way valves. Direct-acting valves are simple and effective for low-pressure applications, making them ideal for small machinery. In contrast, pilot-operated valves utilize a small pilot signal to control a larger flow, suitable for high-pressure systems or larger equipment setups.

Applications for pneumatic solenoid valves span numerous industries, from manufacturing to automotive and beyond. For instance, 3/2-way valves are frequently used in applications requiring the switching of airflow, such as clamping or lifting operations. Additionally, the configuration of these valves can be adjusted for unique requirements, including normally closed or normally open positions. As automation continues to expand, the versatility and reliability of pneumatic solenoid valves make them indispensable for improving operational efficiency across various sectors.

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

| Pneumatic Solenoid Valve Type | Operating Voltage (V) | Flow Rate (L/min) | Port Size (mm) | Application |

|---|---|---|---|---|

| 2/2 Way Normally Closed | 12 | 300 | 1/4 | General Automation |

| 3/2 Way Normally Open | 24 | 450 | 1/8 | Control Air Flow |

| 4/2 Way Double Acting | 110 | 600 | 3/8 | Cylinders Operation |

| 5/2 Way Pneumatic Valve | 24 | 500 | 1/2 | Actuator Control |

| Low Pressure Solenoid Valve | 12 | 200 | 1/4 | Vacuum Applications |

| High Flow Solenoid Valve | 24 | 800 | 3/4 | Material Handling |

| Miniature Solenoid Valve | 12 | 150 | 1/8 | Compact Systems |

| ISO Standard Solenoid Valve | 24 | 400 | 1/2 | Industrial Equipment |

| Double Acting Solenoid Valve | 110 | 550 | 3/8 | Robotic Applications |

| Explosion Proof Solenoid Valve | 24 | 300 | 1/4 | Hazardous Environments |

Key Features to Consider for Optimal Pneumatic Solenoid Valve Selection

When selecting pneumatic solenoid valves to enhance automation efficiency, several key features should be prioritized. One major aspect to consider is the valve response time; a faster response can significantly improve system performance. According to a report by MarketsandMarkets, the global pneumatic valve market is expected to grow at a CAGR of 4.8% from 2023 to 2028, underlining the increasing demand for high-performance components in automation systems. A quicker actuation can reduce cycle times, enhance productivity, and minimize energy consumption, making it a critical factor in valve selection.

When selecting pneumatic solenoid valves to enhance automation efficiency, several key features should be prioritized. One major aspect to consider is the valve response time; a faster response can significantly improve system performance. According to a report by MarketsandMarkets, the global pneumatic valve market is expected to grow at a CAGR of 4.8% from 2023 to 2028, underlining the increasing demand for high-performance components in automation systems. A quicker actuation can reduce cycle times, enhance productivity, and minimize energy consumption, making it a critical factor in valve selection.

Another essential feature is the valve's compatibility with operating conditions, including pressure range and media type. Selecting a valve that can withstand the specific demands of a given application is vital; for instance, a study published in the Journal of Automation Science revealed that improperly rated valves can lead to failures, increasing maintenance costs by up to 20%. Additionally, features such as low power consumption and compact design should be evaluated, as they can contribute to the overall sustainability and efficiency of the automation system. By considering these key features, users can ensure optimal performance and longevity of their pneumatic solenoid valves.

Comparison of Top 10 Pneumatic Solenoid Valves for Automation Efficiency

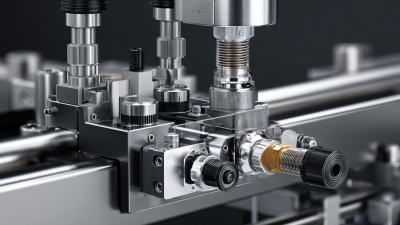

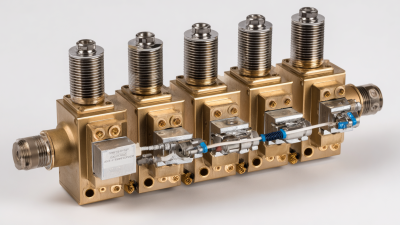

When choosing the best pneumatic solenoid valves for enhancing automation efficiency, a comprehensive comparison of top options is crucial. Pneumatic solenoid valves serve as essential components in automation systems, controlling airflow to tools and equipment. The efficiency of these valves directly impacts response times and overall system performance, making it vital to assess several key features, including durability, flow rate, and electrical specifications.

In examining the top 10 pneumatic solenoid valves, factors such as operating pressure ranges, compatibility with various pneumatic systems, and ease of installation come into play. Many leading brands offer innovative solutions that leverage advanced materials and technology, ensuring superior performance even in demanding environments. Valves equipped with integrated feedback systems or enhanced sealing mechanisms further contribute to reliable operation and reduced maintenance needs, thereby optimizing automation efficiency. By analyzing these comparative features, engineers can make informed decisions that align with their automation goals.

Innovative Technologies in Pneumatic Solenoid Valves: Enhancing Performance

Innovative technologies in pneumatic solenoid valves are transforming the landscape of automation efficiency. One of the most significant advancements is the integration of smart sensors that enable real-time data monitoring. These sensors can detect pressure fluctuations and flow rates, providing feedback to control systems that optimize operation. This not only enhances the responsiveness of the valves but also reduces the potential for malfunctions, leading to increased system reliability and lower maintenance costs.

Another important innovation is the development of energy-efficient solenoid designs. Modern pneumatic solenoid valves are now available with low power consumption features, allowing for substantial energy savings without sacrificing performance. These designs often include advanced coil technology that minimizes heat generation and extends the lifespan of the valve. Additionally, improvements in materials used in construction provide enhanced durability and resistance to wear, making these components better suited for the rigors of continuous use in automated systems. Overall, these technological enhancements are crucial for improving performance and efficiency in various automation applications.

Maintenance Tips for Prolonging the Life of Pneumatic Solenoid Valves

Maintaining pneumatic solenoid valves is crucial for ensuring their longevity and optimal performance in automation systems. Regular maintenance not only boosts efficiency but also helps prevent costly breakdowns. One key tip is to frequently inspect seals and fittings for wear and tear. Over time, seals may degrade, leading to leaks that can compromise functionality. Replacing worn components promptly can significantly extend the valve's operational life.

Another important aspect of maintenance is to keep the valves clean and free of debris. Accumulated dust and particles can obstruct valve mechanisms, impacting their responsiveness and reliability. Using a compressed air spray or a soft brush can effectively clear away contaminants. Additionally, consider implementing a routine schedule for lubricating moving parts according to the manufacturer’s specifications, which can help maintain smooth operation and reduce friction-related wear.

Lastly, it is essential to monitor the operating environment. Factors such as temperature, humidity, and exposure to corrosive substances can affect the performance and lifespan of pneumatic solenoid valves. By choosing valves that are suited for specific operational conditions and making adjustments to environmental factors where possible, users can significantly enhance the reliability and durability of their automation systems.

Related Posts

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries