Top Uses of Pneumatic Actuators in Modern Industry?

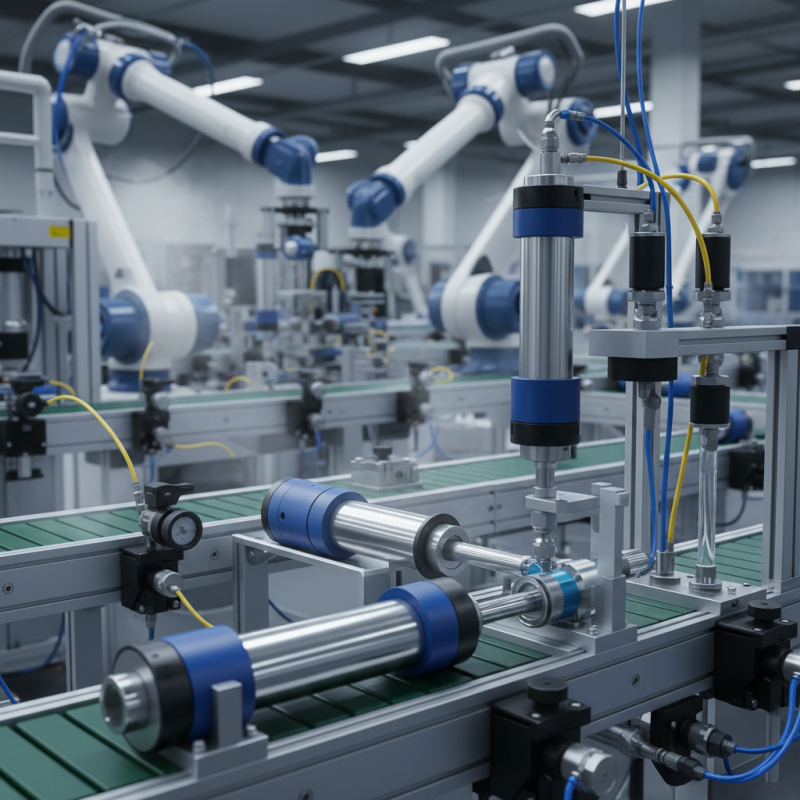

Pneumatic actuators play a crucial role in modern industry. These devices convert compressed air into mechanical motion. They are widely used in various applications, from manufacturing to automation. Many industries rely on pneumatic actuators for their efficiency and effectiveness.

In manufacturing, pneumatic actuators control processes with precision. They activate valves and control fluids in production lines. Their speed and reliability reduce downtime. Yet, not all implementations are perfect. Some systems face challenges with pressure fluctuations and maintenance costs.

Automation also benefits from pneumatic actuators. They enable quick responses to control signals. This enhances productivity and safety. However, their dependency on air supply poses risks. Interruptions can halt operations unexpectedly. Businesses must weigh these pros and cons when choosing pneumatic actuators.

Applications of Pneumatic Actuators in Manufacturing Processes

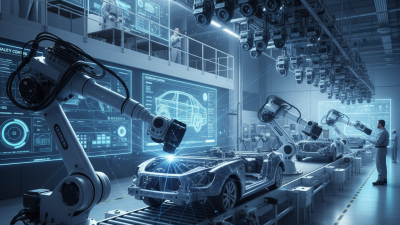

Pneumatic actuators play a crucial role in modern manufacturing processes. These devices convert compressed air into mechanical energy. They provide high-speed operation, making them ideal for tasks requiring quick movements. In assembly lines, pneumatic actuators control the movement of robotic arms. They swiftly pick and place products, enhancing productivity. Moreover, their simplicity allows for easy maintenance, though the need for constant air supply can be a drawback.

In packaging applications, pneumatic actuators ensure precise sealing and filling. They can apply the necessary force to close boxes tightly. This helps prevent product damage. The flexibility of these actuators also supports various sizes and shapes of packages. However, fluctuations in air pressure can lead to inconsistent performance. It’s essential to monitor and adjust air supply for optimal efficiency.

Pneumatic actuators are also vital in food and beverage industries. They facilitate the automation of processes like bottling and capping. Fast operational speeds help meet high-demand production rates. Yet, hygiene standards must be prioritized to avoid contamination. Regular cleaning and maintenance of actuators are crucial. Overall, while pneumatic actuators enhance efficiency, attention to detail is necessary for successful implementation.

Role of Pneumatic Actuators in Material Handling Systems

Pneumatic actuators play a vital role in modern material handling systems. These devices use compressed air to create motion, making them ideal for moving various materials. From lifting heavy loads to precisely controlling conveyor belts, their versatility is unmatched. In warehouses, pneumatic actuators simplify repetitive tasks and improve efficiency. They can be found in automated systems, where precision is key.

Tips: When implementing pneumatic actuators, consider the system's air supply. Ensure your compressor can handle the demand. It’s also wise to regularly check for leaks. Small leaks can lead to significant inefficiencies.

Companies often overlook maintenance. Neglecting this can lead to unexpected downtime. Simple routine checks can prevent bigger issues down the line. Employees should be trained on how to maintain equipment properly. A well-maintained system is more reliable and cost-effective. Be cautious of overloading actuators; it can shorten their lifespan.

Top Uses of Pneumatic Actuators in Modern Industry

| Use Case | Description | Benefits | Industry Applications |

|---|---|---|---|

| Material Handling | Automated movement of materials within manufacturing facilities. | Increased efficiency and reduced manual labor. | Manufacturing, Warehousing |

| Packaging | Used for the precise actuation in packaging machines for sealing and filling. | Improved speed and accuracy in packaging processes. | Food & Beverage, Pharmaceuticals |

| Assembly Lines | Facilitating the assembly of components in a production line. | Lower production costs and reduced assembly time. | Automotive, Electronics |

| Robotics | Enabling precise movement and control in robotic systems. | Enhanced versatility and performance of robots. | Manufacturing, Surgical Robotics |

| Textile Production | Controlling machines for cutting, sewing, and processing textiles. | Increased throughput and quality control. | Textile, Fashion |

Impact of Pneumatic Actuators on Automation and Robotics

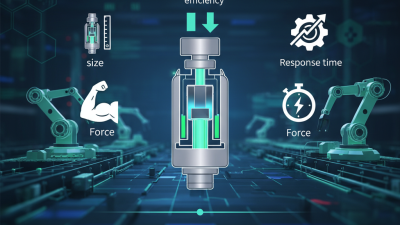

Pneumatic actuators are crucial in modern industry. They provide efficient motion control in automation and robotics. These devices use compressed air to create mechanical movement. Their lightweight and compact nature makes them ideal for various applications.

In automation, pneumatic actuators enable precise control over machinery. They excel in moving parts quickly and accurately. They can automate repetitive tasks, saving time and reducing human error. Robots use these actuators to perform delicate operations in manufacturing. This enhances productivity and allows for complex assembly processes.

**Tip:** Regular maintenance of pneumatic systems ensures optimal performance. Neglecting this can lead to leaks and reduced efficiency.

In robotics, the response time of pneumatic actuators is impressive. Their ability to deliver high force in a short timeframe is invaluable. However, they can sometimes be inconsistent. Air supply issues can cause delays in movement, which may disrupt operations.

**Tip:** Monitor air supply levels regularly to avoid operational hiccups.

In summary, pneumatic actuators significantly impact automation and robotics. Their advantages in speed and reliability are evident. However, companies must remain aware of potential challenges. Addressing these issues can lead to more efficient operations.

Advantages of Pneumatic Actuators in Fluid Control Applications

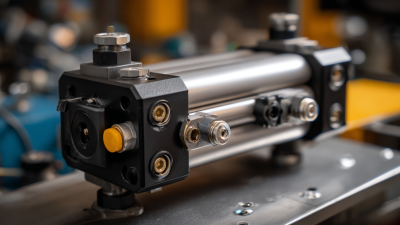

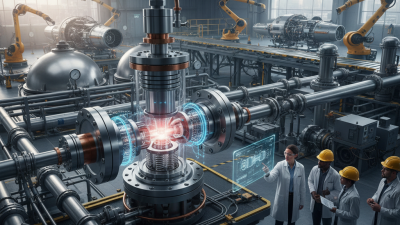

Pneumatic actuators play a crucial role in fluid control applications across various industries. They harness compressed air to push or pull components. This technology allows for rapid and efficient movement, making it ideal for assembly lines.

The advantages of pneumatic actuators are notable. They provide quick response times and high efficiency. Maintenance is generally straightforward, but it can become complicated. Leaks in the system may reduce performance. In some instances, operators might overlook these issues, leading to decreased effectiveness. Furthermore, the force they exert can be significant, allowing for the control of heavy loads safely.

These actuators also come with environmental benefits. They generate less waste when compared to electric actuators. However, the reliance on compressed air may raise energy costs. Overall, understanding the strengths and limitations of pneumatic actuators is vital. This awareness helps companies optimize their operations and enhance overall productivity.

Top Uses of Pneumatic Actuators in Modern Industry

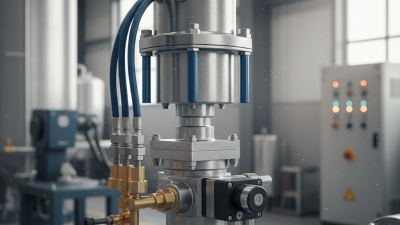

Pneumatic actuators play a crucial role in a variety of industries by providing reliable and efficient control for fluid systems. The above chart illustrates the distribution of their applications across multiple sectors, highlighting the significance of these devices in modern industrial practices.

Safety and Maintenance Considerations for Pneumatic Actuators

Pneumatic actuators play a vital role in modern industry, but safety and maintenance are crucial. Regular maintenance prevents unexpected breakdowns. Neglecting simple checks can lead to expensive repairs. It’s essential to monitor the system’s air pressure. Low pressure can cause slow response times. Conversely, excessive pressure can damage components.

Tips: Keep a maintenance log. This helps track service intervals and identify patterns. Consider creating a checklist for routine inspections. Check for air leaks regularly. Even small leaks can affect performance. Pay attention to the actuator’s environment. Dust and contaminants can harm functionality.

Training personnel is equally important. Workers should understand how pneumatic systems operate. They must know the potential hazards. An untrained operator may overlook critical safety protocols. Always ensure that emergency shut-off valves are accessible. This can prevent severe accidents in case of failure. Regular safety drills can help reinforce this knowledge.

Related Posts

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

-

What is a Pneumatic Control Valve and How Does It Work?

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

-

2026 Best Air Solenoid Options for Efficient Automation Solutions?

-

Top Machine Vision System Applications for Industry and Innovation?

-

What is a High Pressure Pneumatic Valve and How Does It Work

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries