Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

The advancement of pneumatic actuators is playing a crucial role in the evolution of automation solutions across various industries. As we look ahead to 2025, innovative developments in pneumatic actuator technology promise to enhance efficiency, precision, and reliability in automated systems. These innovations are driven by the need for improved performance, reduced energy consumption, and the incorporation of smart technologies that allow for better integration and control within complex industrial processes.

In this article, we will explore the latest trends and innovations in the field of pneumatic actuators. We will delve into how these advancements are shaping automation solutions by examining the integration of new materials, advanced control systems, and enhanced design features that cater to the demands of modern industry. From increased responsiveness to adaptive functionalities, the innovations in pneumatic actuators are set to transform the landscape of automation, making processes more streamlined and effective. Join us as we uncover the top innovations that are expected to redefine the capabilities of pneumatic actuators by 2025 and beyond.

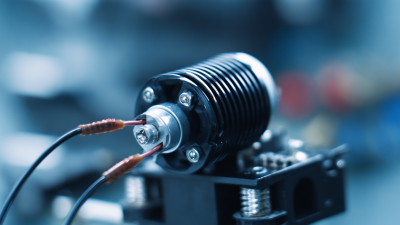

Revolutionary Materials in Pneumatic Actuator Design for Improved Efficiency

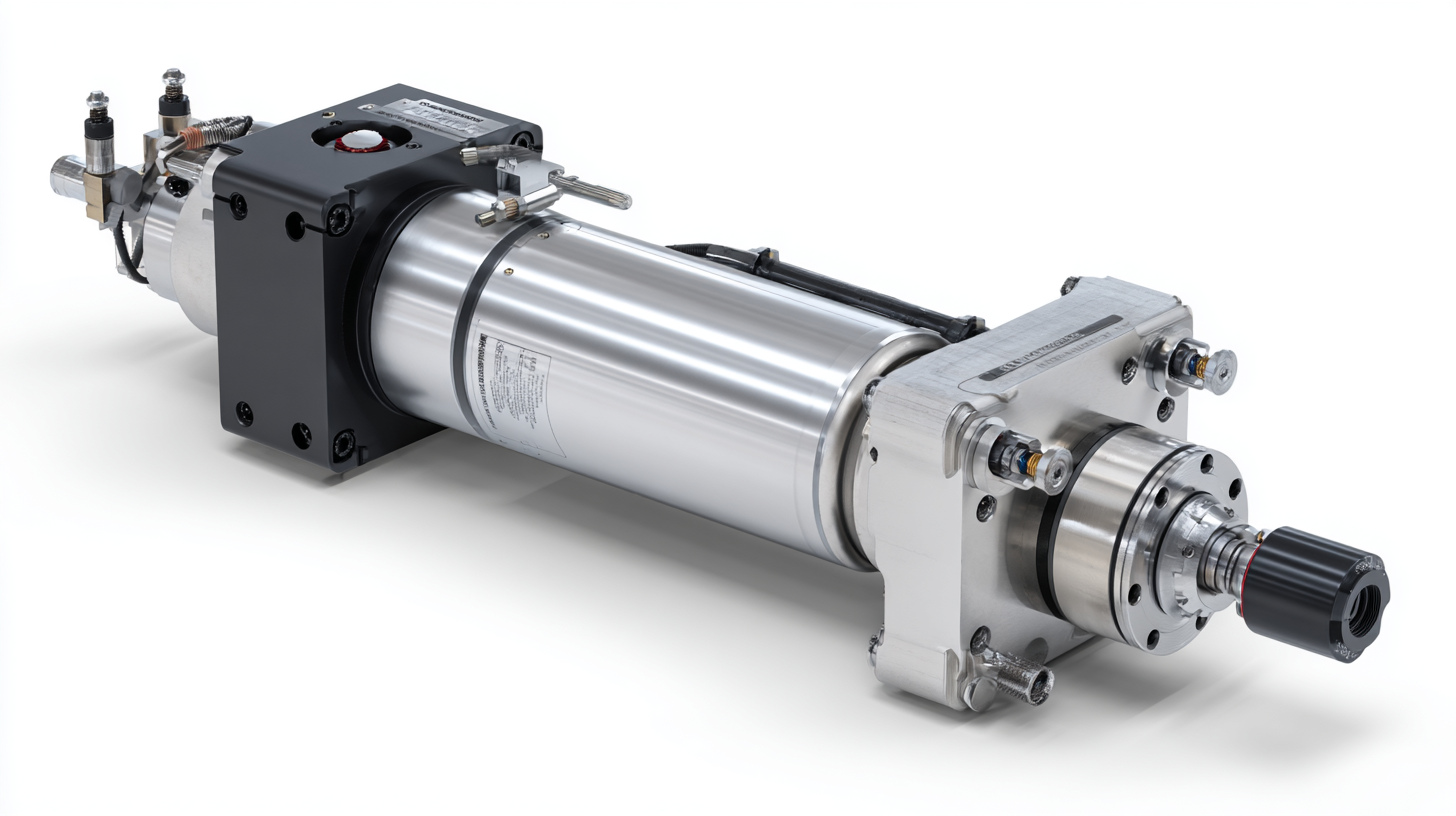

The landscape of pneumatic actuator design is experiencing a significant transformation with the introduction of revolutionary materials that promise to enhance efficiency and functionality. One notable advancement is the development of untethered soft actuators, which are essential for the movement of soft robots. These actuators provide the necessary mechanical force, yet they face challenges that require innovative material solutions to overcome limitations in performance and flexibility.

Future innovations in pneumatic actuators are leaning toward the integration of functional polymeric materials through advanced manufacturing techniques, such as 3D printing. This allows for greater design customization, resulting in actuators that are not only lightweight but also highly efficient. The use of smart materials can drastically improve not just the actuator design, but also their application in various fields, including healthcare and robotics.

Tips: When selecting materials for pneumatic actuators, consider those that offer self-healing properties for enhanced longevity. Additionally, incorporating 3D-printed components can provide the desired rapid prototyping capabilities, allowing for quick iterations in design and performance testing.

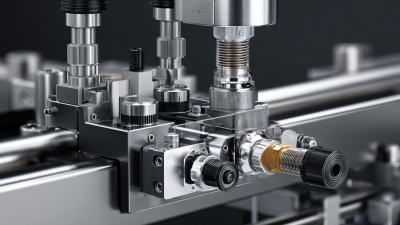

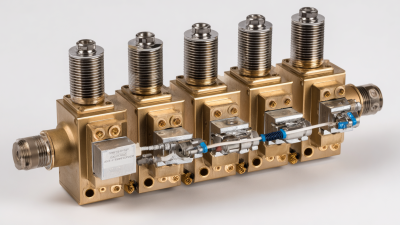

Smart Pneumatic Actuators: Integrating IoT for Real-Time Monitoring

As industries continue to embrace automation, the integration of smart pneumatic actuators with IoT technology is revolutionizing operational efficiency. According to a report by Market Research Future, the smart actuator market is expected to grow significantly, with a projected CAGR of over 10% from 2021 to 2027. This growth is largely driven by advancements in IoT, which enable real-time monitoring and data analytics capabilities that are critical for enhancing automation solutions.

Smart pneumatic actuators, equipped with sensors and connectivity features, allow for real-time performance tracking. These IoT-enabled devices can send vital performance data directly to maintenance teams, alerting them to potential issues before they lead to costly downtime. For instance, predictive maintenance enabled by smart actuators can reduce maintenance costs by up to 30%, according to a recent study by McKinsey & Company.

Tip: When considering the implementation of smart pneumatic actuators, ensure your existing infrastructure supports IoT integration. Assess compatibility with current systems and choose devices that offer robust data control capabilities for maximum efficiency. This proactive approach can lead to significant improvements in productivity and operational reliability.

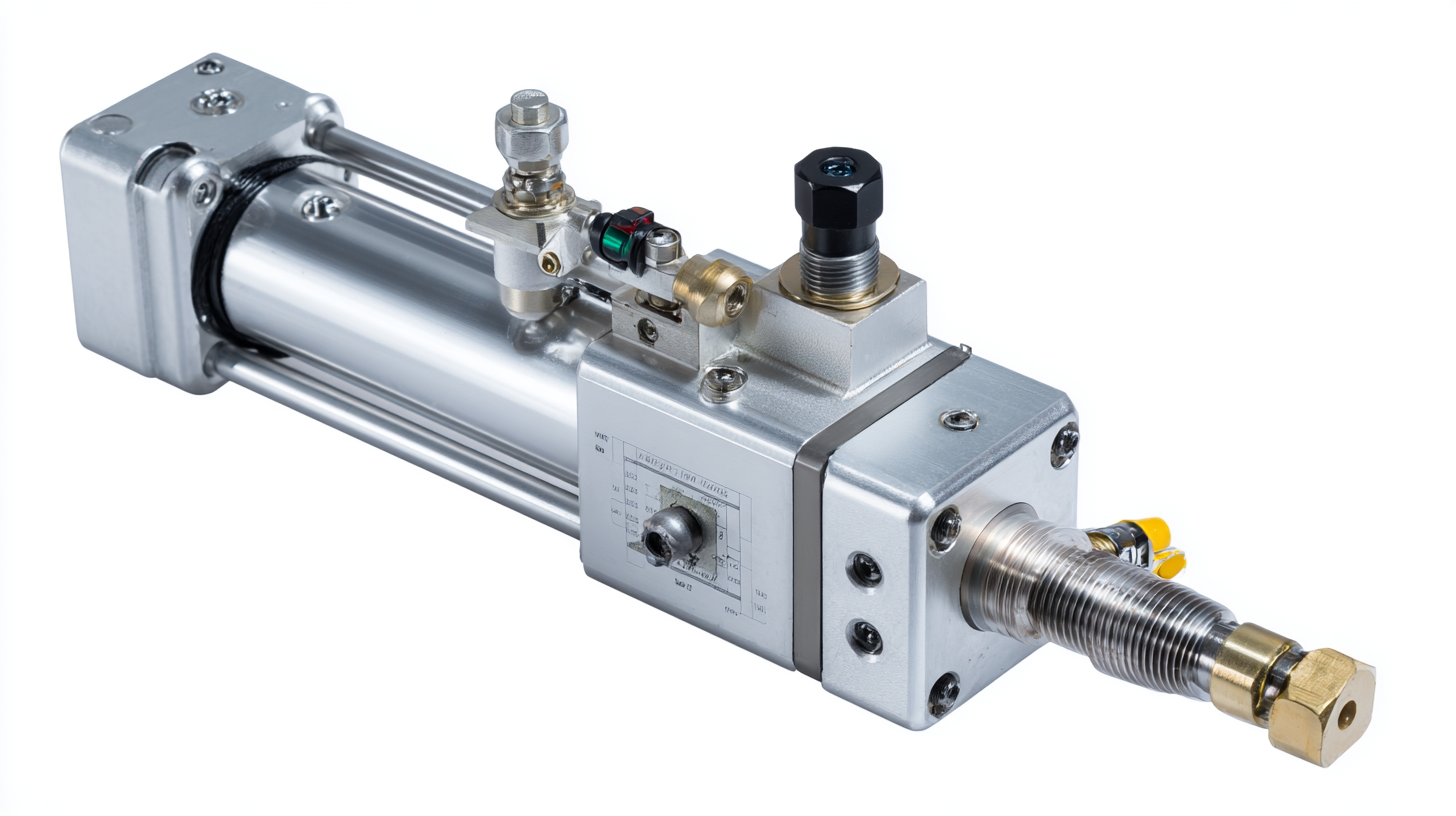

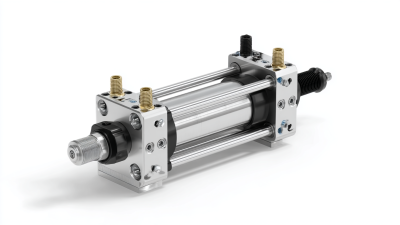

Energy-Efficient Pneumatic Actuators: Reducing Operational Costs in Automation

The rise of energy-efficient pneumatic actuators marks a significant shift in automation solutions. According to the International Energy Agency (IEA), energy efficiency improvements in industrial applications can lead to cost savings of up to 30%. The latest innovations in pneumatic actuator technology are designed not only to enhance performance but also to minimize energy consumption and operational costs. For instance, advanced materials and designs are now enabling actuators to operate at lower pressures while maintaining the same output force, making processes more sustainable.

Tips: To maximize the efficiency of your pneumatic systems, consider implementing variable speed drives to adjust the power supply according to operational requirements. Regular maintenance and monitoring can also help identify leaks or inefficiencies, further improving energy usage.

In addition to cost savings, the shift towards energy-efficient pneumatic actuators can also significantly reduce a facility's carbon footprint. According to a recent report by Markets and Markets, the global market for energy-efficient automation solutions is projected to reach $30 billion by 2025, reflecting the industry’s commitment to sustainability. By adopting these innovative systems, companies not only improve their bottom line but also contribute to environmental conservation efforts, aligning with global sustainability goals.

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

| Innovation | Description | Energy Efficiency (%) | Operational Cost Reduction (%) | Application Area |

|---|---|---|---|---|

| Smart Flow Control | Advanced sensors for optimized air flow control in processes. | 25% | 15% | Manufacturing |

| Adaptive Actuator Technology | Adjusts power usage based on load conditions. | 30% | 20% | Automotive |

| Compact Design Improvements | Smaller size actuators that require less energy to operate. | 20% | 10% | Robotics |

| Leak Detection Systems | Integrated systems for early detection of pneumatic leaks. | 15% | 12% | Food Processing |

| AI-Driven Performance Monitoring | Utilizes AI for predictive maintenance and operational insights. | 35% | 25% | Oil & Gas |

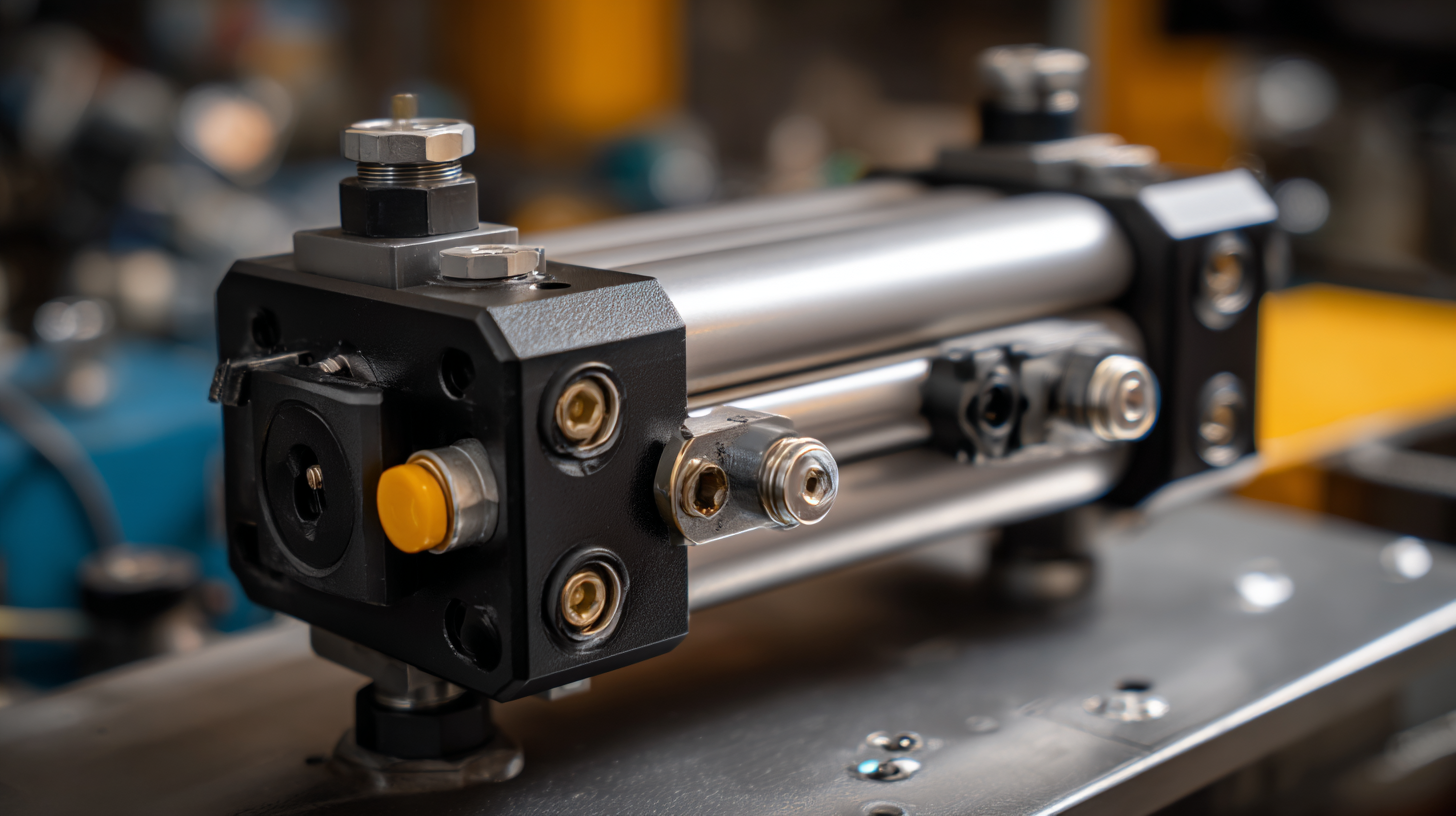

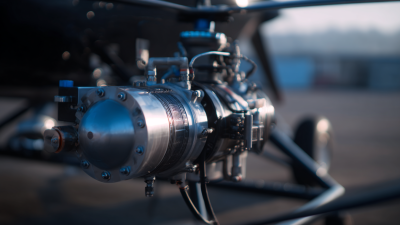

Advanced Control Techniques: Enhancing Precision in Pneumatic Actuation

Advanced control techniques in pneumatic actuation are reshaping the landscape of industrial automation, significantly enhancing precision and responsiveness in various applications. As industries demand greater efficiency and accuracy, innovations such as closed-loop control systems and smart sensors are becoming pivotal. These technologies allow for real-time monitoring and adjustments, ensuring that pneumatic actuators function with utmost precision. This level of control minimizes the risk of errors, contributing to increased productivity and reduced waste.

Moreover, the integration of machine learning algorithms into control systems is revolutionizing the way pneumatic actuators operate. By analyzing vast amounts of operational data, these algorithms can predict potential failures and optimize performance metrics dynamically. This proactive approach not only enhances the longevity of the actuators but also ensures that they can adapt to changing operational conditions, leading to a more streamlined automation process. With these advancements, businesses are better positioned to meet the ever-evolving demands of the market, ultimately driving forward the future of automation solutions.

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

Sustainable Innovations: Eco-friendly Practices in Pneumatic Actuator Manufacturing

The focus on sustainable innovations within the pneumatic actuator manufacturing sector is timely, particularly as global investments in green technology hit record highs. As industries are increasingly urged to adopt eco-friendly practices, pneumatic actuators are evolving to meet these demands. Manufacturers are exploring sustainable materials and processes to minimize their environmental impact while enhancing performance. This shift not only aligns with global sustainability goals but also caters to market pressures for greener automation solutions.

Among the innovative practices emerging in 2025, the integration of recyclable materials in actuator components and energy-efficient production methods stands out. Manufacturers are leveraging advances in technology, such as generative design and smart manufacturing techniques, to reduce waste and energy consumption. These developments are crucial as businesses strive to balance growth with environmental responsibility, ensuring that pneumatic actuators contribute positively to the automation landscape while supporting broader eco-friendly initiatives.

Related Posts

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries