Top 10 High Pressure Pneumatic Valve Uses and Benefits?

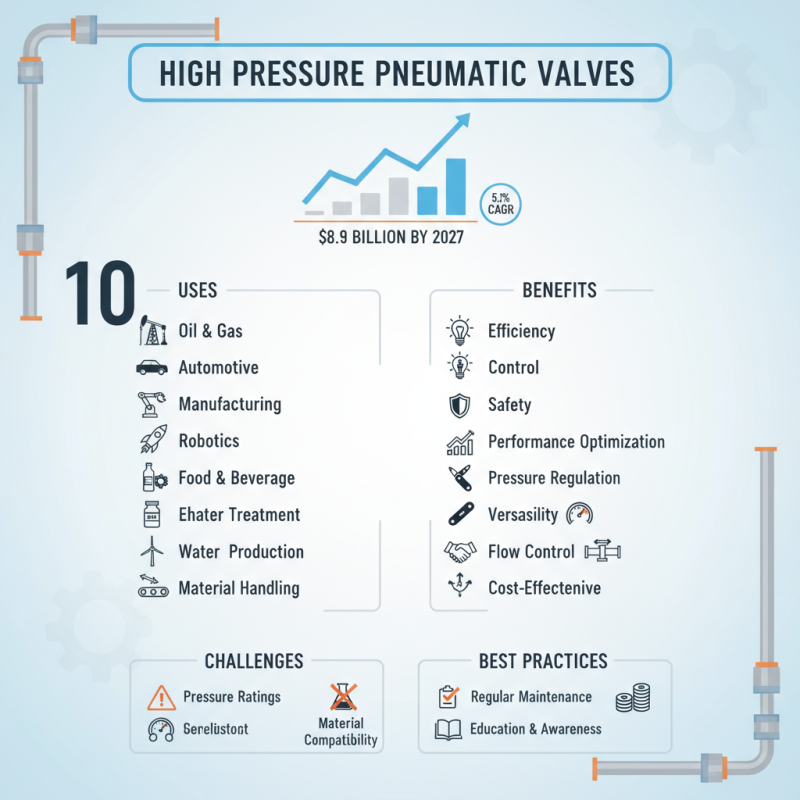

High pressure pneumatic valves play a crucial role in various industries, ensuring efficient control in systems that require precise pressure management. According to recent market reports, the global pneumatic valve market is expected to reach $8.9 billion by 2027, growing at a CAGR of 5.2%. This growth highlights the increasing reliance on high pressure pneumatic valve applications in sectors such as oil and gas, automotive, and manufacturing.

These valves are designed to withstand significant pressure while providing reliable operation. From controlling the flow of compressed air to regulating pressure in pneumatic systems, their versatility is unmatched. Industries utilize these valves for safety, efficiency, and performance optimization. However, the implementation of high pressure systems also presents challenges. Operators must be cautious about pressure ratings and material compatibility to avoid potential failures.

In addition, regular maintenance is often overlooked, leading to inefficiencies. Awareness and education can improve performance and lifespan. As industries evolve, the demand for high pressure pneumatic valves continues to increase, yet there remains a critical need for best practices and continuous improvement in application methods.

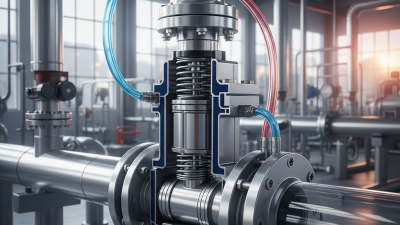

Overview of High Pressure Pneumatic Valves and Their Functionality

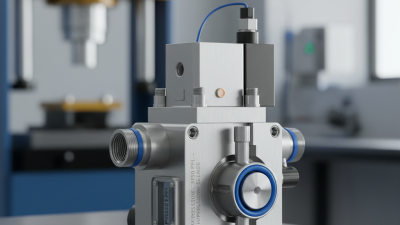

High pressure pneumatic valves are essential components in various industrial applications. They control the flow of gases under high pressure, making them vital for automotive, food processing, and chemical industries. These valves operate using compressed air, allowing for swift action and precise regulation. Their design enhances safety and efficiency in operations.

The functionality of these valves is rooted in their ability to manage extreme conditions. They can handle significant pressure and temperature variations. However, not all high pressure pneumatic valves perform optimally in every situation. Choosing the wrong valve can lead to inefficiencies. For instance, valve sizes impact flow rates. Miscalculating flow requirements may result in performance issues.

Moreover, regular maintenance is crucial. Neglecting this can lead to wear and tear. This might compromise safety and efficiency. Operators often overlook the importance of routine checks. It's a reflection of the need for better oversight in valve management. Thus, understanding their functionality is not just beneficial; it is necessary for operational integrity.

Top 10 High Pressure Pneumatic Valve Uses and Benefits

This chart displays the benefit scores of high-pressure pneumatic valves across various industries. The scores represent the levels of effectiveness and importance in each sector, highlighting the versatility and necessity of these valves in numerous applications.

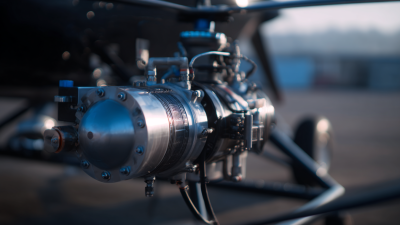

Key Applications of High Pressure Pneumatic Valves in Industries

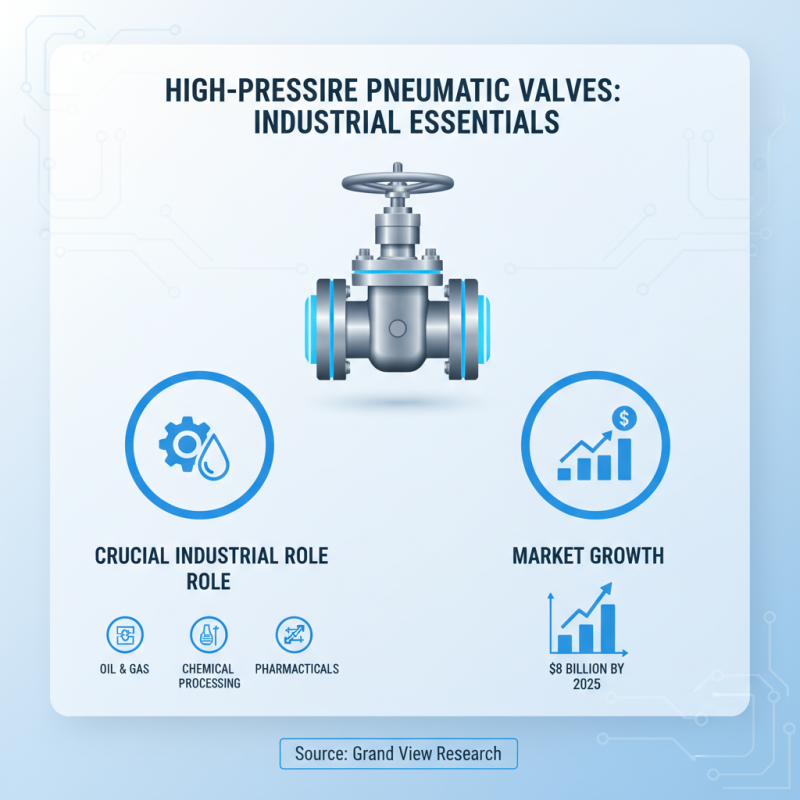

High-pressure pneumatic valves play a crucial role in various industries. They're essential in sectors like oil and gas, chemical processing, and pharmaceuticals. These valves are designed to handle extreme pressures. According to a report by Grand View Research, the global pneumatic valve market is expected to reach $8 billion by 2025. This growth highlights the importance of these valves in modern industry.

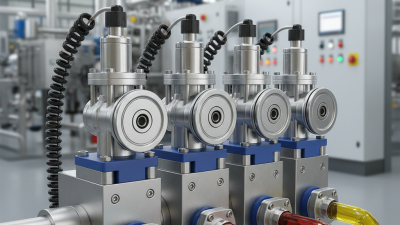

One key application is in automation systems. High-pressure pneumatic valves control the flow of air or gas in machines. They help maintain optimal performance. Another vital use is in safety systems. These valves prevent overpressure situations. They operate quickly, ensuring safety and efficiency.

Tips: Always consider the specific pressures and gases you'll use. Not all valves suit every application. Regular maintenance is essential but often overlooked. Check for wear and tear to avoid breakdowns.

High-pressure environments test valve durability. Certain types may fail under extreme conditions. Evaluating your pneumatic system helps prevent costly repairs. Investing in good quality valves can save money in the long run.

Benefits of Utilizing High Pressure Pneumatic Valves for Automation

High pressure pneumatic valves play a crucial role in automation systems. Their design allows them to handle extreme pressures and maintain efficiency. Many industries rely on these valves for their durability and reliability. They are often used in applications like manufacturing, packaging, and food processing. These valves ensure precise control of airflow and fluid flow.

Utilizing high pressure pneumatic valves streamlines processes. They reduce operational downtime and maintenance costs. Automation enhances productivity, allowing for faster production cycles. In some cases, users report challenges in calibrating and maintaining these systems. A small error in setup can lead to inefficiencies. Ensuring regular checks is essential, but it can be overlooked.

The benefit of these valves lies in their ability to manage pressure with precision. This capacity boosts overall system performance. The automation of valves minimizes human intervention, yet it requires constant oversight. Balancing automation with human checks creates a safer and more efficient environment. Continuous improvement and attention to detail are necessary for optimal performance.

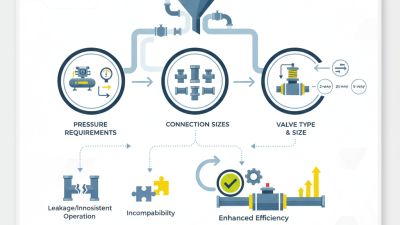

Comparative Analysis of Different Types of High Pressure Pneumatic Valves

High pressure pneumatic valves play a crucial role in various industrial applications, providing control over air and gas flows. Different types of valves, such as globe, ball, and needle valves, have unique functionalities. For instance, globe valves are ideal for throttling, while ball valves offer excellent sealing capabilities. According to a report from Industry Research, the global pneumatic valve market is expected to grow significantly, reaching $10 billion by 2025.

When comparing high pressure pneumatic valves, consider parameters like pressure ratings and material composition. Steel valves are common, but polymers can also be effective in certain environments. Reports suggest that valves made from corrosion-resistant materials last longer, reducing maintenance costs. It's essential to select the right type for your specific application. An ill-suited valve can lead to leaks or system failures.

Tips: Always evaluate operation conditions. Assessing temperature, pressure, and media type is vital. Choose a material that resists corrosion. Regular maintenance checks can enhance longevity. Remember, an informed choice leads to better performance and efficiency in your system.

Maintenance Practices for Ensuring Optimal Performance of Pneumatic Valves

Pneumatic valves play a crucial role in many industrial applications. Regular maintenance is key to ensuring they operate effectively. Over time, dirt and debris can build up, impacting performance. It is essential to keep these components clean. Inspecting valve seals regularly can also help avoid leaks.

One tip for maintenance is to conduct periodic functional tests. This allows you to identify any issues early. Additionally, review the piping and connections for wear. A loose connection can cause pressure drops, leading to system inefficiencies. Consider replacing components that show signs of fatigue.

Lubrication is another vital practice. Use the right fluid to prevent corrosion and ensure smooth operation. However, avoid over-lubrication. Excess lubricant can attract dirt, which might negate its benefits. Reflect on how often you check these factors; sometimes we overlook routine tasks. Consistent attention can lead to longer valve life and fewer breakdowns.

Related Posts

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

What Are Pneumatic Operated Valves and How Do They Work?

-

How to Choose the Right Pneumatic Solenoid Valve for Your Application?

-

Top 2025 Humphrey Air Valve Types: What You Need to Know for Optimal Performance

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries