Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

As industries continue to evolve in the face of rapid technological advancement, the essential role of pneumatic components in automation has become increasingly pronounced. According to a report by the International Federation of Robotics, the global market for industrial automation is projected to reach over $150 billion by 2025, with pneumatic systems being a critical enabler for efficiency and reliability.

These components facilitate motion control, energy transfer, and system integration across various sectors, including manufacturing and logistics. As companies strive to enhance productivity and reduce operational costs, the demand for pneumatic components is anticipated to rise significantly, driving innovation and efficiency within automated systems. This article explores the future of automation and highlights how pneumatic components are transforming modern industries, ensuring seamless operations and fostering sustainable growth.

These components facilitate motion control, energy transfer, and system integration across various sectors, including manufacturing and logistics. As companies strive to enhance productivity and reduce operational costs, the demand for pneumatic components is anticipated to rise significantly, driving innovation and efficiency within automated systems. This article explores the future of automation and highlights how pneumatic components are transforming modern industries, ensuring seamless operations and fostering sustainable growth.

The Impact of Pneumatic Components on Automation Efficiency

The Impact of Pneumatic Components on Automation Efficiency

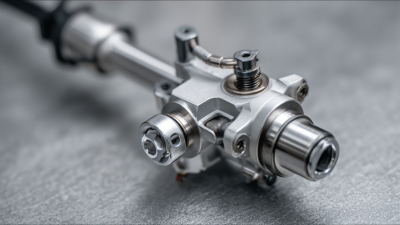

Pneumatic components play an essential role in enhancing automation efficiency across various industries. In recent years, the adoption of pneumatic systems has surged, driven by their versatility and reliability. According to a report by Research and Markets, the global pneumatic components market is expected to grow at a CAGR of 4.9% from 2021 to 2026, reflecting the increasing demand for automation solutions. These components, such as actuators, valves, and compressors, contribute significantly to the performance of automated systems by providing precise control and quick response times, crucial for maintaining productivity in manufacturing processes.

Incorporating pneumatic technologies allows industries to achieve higher levels of automation, often translating to reduced operational costs and increased output. A study by the International Federation of Robotics indicated that the use of advanced automation technologies could boost productivity by up to 30% in manufacturing environments. By integrating pneumatic components, companies can streamline processes, reduce cycle times, and enhance overall system reliability.

**Tips:** When implementing pneumatic solutions, consider regular maintenance schedules to reduce downtime. Equipping systems with sensors can provide real-time data, allowing for predictive maintenance and better efficiency management. Additionally, investing in high-quality pneumatic components can lead to improved performance and longevity of your automation systems.

Key Advantages of Pneumatic Systems in Industrial Applications

Pneumatic systems have become indispensable in modern industrial applications, offering numerous advantages that enhance operational efficiency. According to a report from the International Society for Automation (ISA), up to 70% of factory automation systems utilize pneumatic components due to their reliability and versatility. These systems can effectively convert compressed air into mechanical energy, driving machinery with precision while minimizing operational downtime.

One of the key benefits of pneumatic systems is their ability to quickly adapt to varying production needs. A survey conducted by the Pneumatic and Hydraulic Systems Association (PHSA) revealed that manufacturers report a 30% increase in productivity when implementing pneumatic technology compared to hydraulic or electric systems. Additionally, pneumatic components are generally lighter and simpler, leading to reduced maintenance costs and longer equipment lifespan. With a focus on sustainability, pneumatic systems also have the advantage of being more energy-efficient, with recent breakthroughs in energy recovery systems enabling companies to significantly lower their energy consumption by up to 25%. This positions pneumatic technology as a crucial player in the evolving landscape of industrial automation.

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

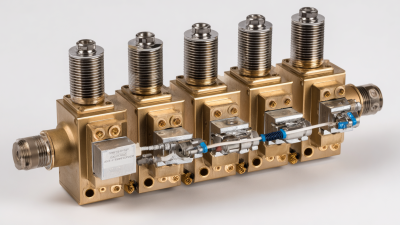

| Pneumatic Component | Industry Application | Key Advantages |

|---|---|---|

| Air Compressor | Manufacturing | High power-to-weight ratio, energy efficiency |

| Pneumatic Cylinder | Automotive | Reliable motion control, simple operation |

| Air Actuator | Food and Beverage | Hygienic operations, safety features |

| Filter Regulator Lubricator (FRL) | Textile | Optimized air quality, system longevity |

| Pneumatic Valves | Electronic Assembly | Fast response times, versatility |

Integrating Pneumatic Technologies with Modern Automation Solutions

The integration of pneumatic technologies with modern automation solutions is increasingly essential in today's fast-paced industrial environment. Pneumatic components, known for their reliability and efficiency, play a crucial role in achieving high levels of automation. They facilitate rapid movements, precise control, and minimal maintenance, making them ideal for applications ranging from assembly lines to packaging systems. As industries focus on optimizing production processes and reducing downtime, pneumatic technologies are often at the forefront, enabling seamless operation alongside electronic and robotic systems.

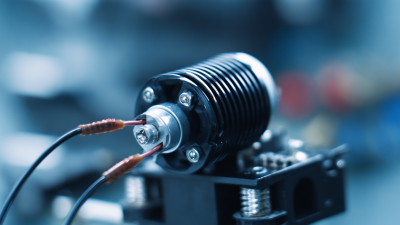

Moreover, the synergistic relationship between pneumatic systems and advanced automation technologies enhances operational flexibility. By incorporating smart sensors and IoT connectivity, pneumatic systems can be monitored and adjusted in real-time, allowing for improved process control and data analysis. This level of integration not only boosts productivity but also supports the predictive maintenance of machinery, mitigating the risk of unexpected failures and costly disruptions. As companies continue to embrace automation, the role of pneumatic components will be critical in shaping a more efficient and innovative industrial landscape.

Exploring the Role of Pneumatic Components in Modern Automation Solutions

This chart illustrates the distribution of different pneumatic component types used in modern industries, highlighting their significance in automation solutions.

Future Trends in Pneumatic Components for Enhanced Industrial Automation

The future of industrial automation is closely linked to the advancements in pneumatic components, which serve as vital enablers of efficiency and productivity. As industries increasingly adopt automated processes, the demand for high-performance pneumatic systems is surging. Future trends indicate a move toward more compact and energy-efficient pneumatic components that utilize smart technologies. These innovations not only reduce the environmental footprint but also enhance process control and simplify integration into existing systems.

Moreover, the integration of IoT (Internet of Things) with pneumatic technology is set to revolutionize how industries operate. This shift allows for real-time monitoring and predictive maintenance of pneumatic systems, which minimizes downtime and optimizes performance. Companies can leverage data analytics to enhance decision-making, thereby achieving greater operational efficiency. The continuous development of advanced materials and designs further contributes to the evolution of pneumatic components, positioning them as indispensable assets in the future landscape of industrial automation.

Real-World Applications of Pneumatic Systems in Various Industries

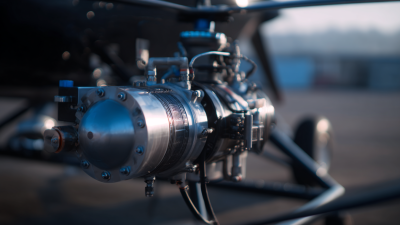

Pneumatic systems play a pivotal role across various industries, leveraging compressed air to power machinery and streamline operations. In manufacturing, for instance, pneumatic components are integral to automate processes such as assembly, painting, and material handling. Their ability to provide precise control and rapid movement enhances production efficiency while reducing the need for manual labor. This not only minimizes errors but also improves workplace safety by taking over hazardous tasks traditionally performed by workers.

In the automotive sector, pneumatic systems are utilized for assembling vehicles and testing components. Machinery like pneumatic wrenches and clamps enables quick assembly lines, significantly accelerating production rates. Additionally, in the food and beverage industry, pneumatically actuated equipment ensures hygienic transport and packaging of products, maintaining compliance with health standards. The adaptability of pneumatic systems to various applications underscores their essential role in fostering innovation and efficiency across modern industries.

Related Posts

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries