The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

In the rapidly evolving fields of automation and fluid control, selecting the right solenoid valve distributors is crucial for optimizing system performance and ensuring reliability. According to a recent market analysis by Research and Markets, the global solenoid valve market is projected to reach USD 5.78 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.9% from 2020. This growth underscores the increasing demand for efficient control systems across various industries, including water treatment, HVAC, and manufacturing. As businesses aim to enhance their operational capabilities, understanding the nuances of solenoid valve distributors becomes essential. Choosing the right distributor not only impacts the quality of the solenoid valves but also influences the overall efficiency and longevity of the systems they support. Therefore, this guide provides valuable insights to navigate the selection process, ensuring that you make informed decisions that align with your specific technical requirements and industry standards.

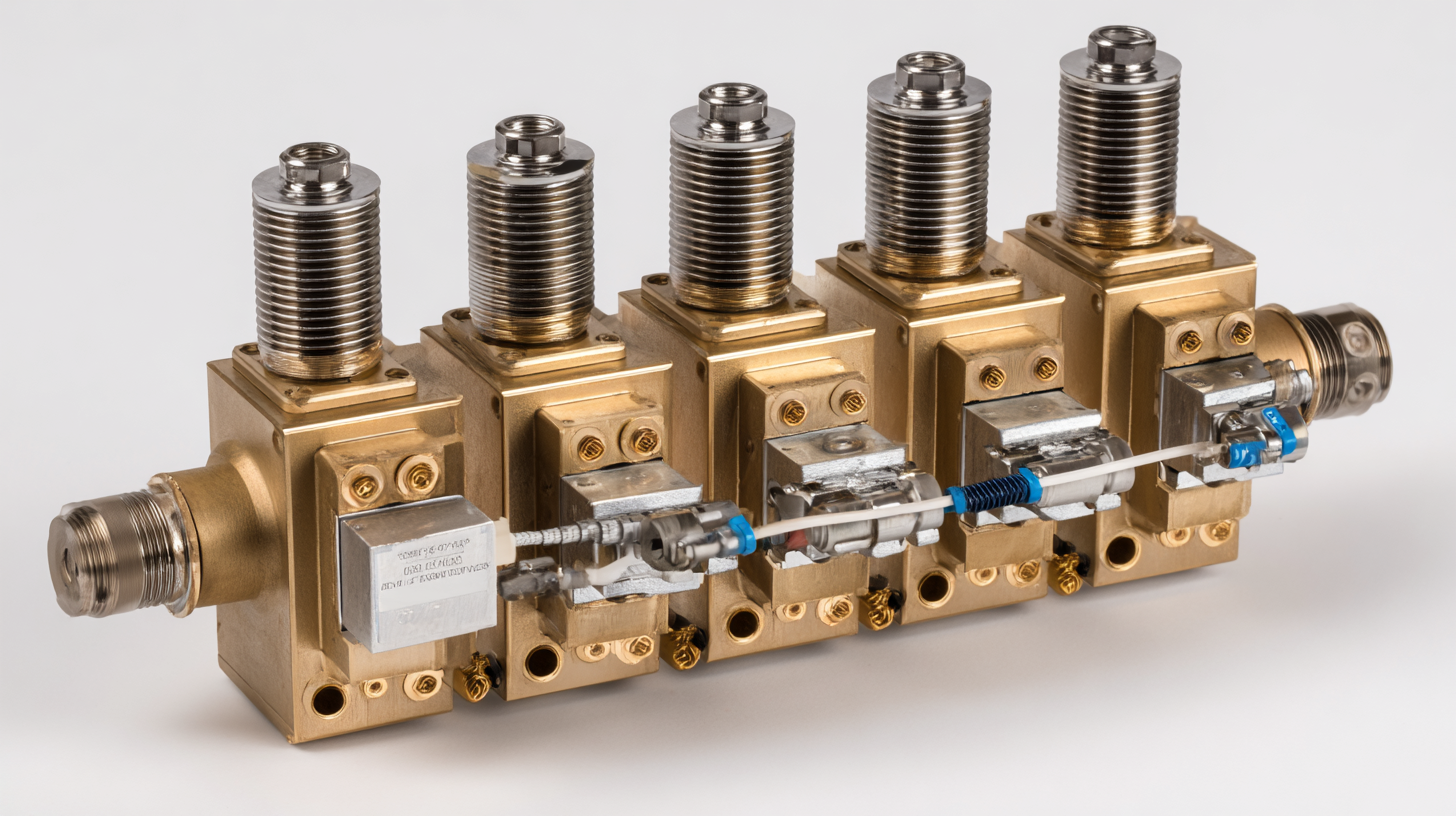

Understanding Solenoid Valve Basics: Types and Applications in Various Industries

Solenoid valves are vital components used in various industries, controlling the flow of liquids and gases with precision. Understanding the types and applications of solenoid valves is essential for selecting the right distributor. According to a report by Fortune Business Insights, the global solenoid valve market is projected to reach USD 4.8 billion by 2026, indicating a significant demand across multiple sectors. The major types of solenoid valves include direct acting, pilot operated, and proportional valves, each catering to specific operational needs.

In industries such as automotive, aerospace, and water management, solenoid valves play crucial roles. For instance, in wastewater treatment, the deployment of solenoid valves enhances efficiency by automating flow control, reducing manual intervention. A study by MarketsandMarkets highlights that automated control systems leveraging solenoid valves can improve operational efficiency by up to 20%. Moreover, in the pharmaceutical industry, these valves are employed for precise dosing applications, where reliability and accuracy are paramount. As the market continues to evolve, understanding these fundamental aspects of solenoid valves will be crucial for making informed distribution choices.

Key Factors to Consider When Selecting a Solenoid Valve Distributor

When selecting a solenoid valve distributor, several key factors can influence your decision. First and foremost, it’s essential to evaluate the distributor's industry experience and expertise. According to a 2021 market analysis by Grand View Research, the global solenoid valve market is projected to reach USD 6.8 billion by 2028. This growth underscores the importance of partnering with a distributor that not only understands the technical details but also keeps abreast of evolving industry trends. Their experience can provide insights into the most effective valve solutions tailored to your specific applications.

Another critical consideration is the range of products offered by the distributor. A diverse inventory ensures you can find the right solenoid valve for various applications, whether it's for HVAC systems or fluid control processes. A study by MarketsandMarkets revealed that innovation in solenoid valve technology is driving the demand for advanced solutions, particularly in automation and smart systems. Distributors that collaborate with leading manufacturers and invest in a wide array of products typically offer better support and can assist in selecting valves that optimize performance while adhering to compliance standards.

The Importance of Certification and Standards in Solenoid Valve Distribution

When selecting solenoid valve distributors, understanding the significance of certification and standards is paramount. Certifications such as ISO, CE, and UL ensure that the products meet specific safety and quality benchmarks, which is crucial for the reliability and performance of solenoid valves in various applications. A distributor that adheres to these standards demonstrates a commitment to providing high-quality products and can significantly reduce the risks of equipment failure.

**Tips:** Always check if the distributor provides documentation of their certifications. This not only offers insight into their commitment to quality but also helps in making informed decisions regarding warranty and support policies.

Moreover, standards play a key role in industry compliance. Distributors who comply with established standards often have better customer support, as they are familiar with the regulatory environment and can assist in navigating through the complexities of compliance. By choosing a distributor that prioritizes certification, customers can ensure they receive reliable products that are less likely to encounter compliance issues down the line.

**Tips:** Establish a relationship with distributors who actively participate in industry associations or standards organizations, as this involvement often reflects their investment in quality and continuous improvement.

Analyzing Market Trends: The Growth of the Solenoid Valve Industry in Recent Years

The solenoid valve industry has experienced significant growth in recent years, driven by advancements in automation and the increasing demand for efficient fluid control systems. According to a recent report by Market Research Future, the global solenoid valve market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2020 to 2027. This growth reflects a burgeoning need for solenoid valves across various applications, including HVAC systems, automotive, and manufacturing processes.

Market Trends indicate that the surge in industrial automation is a key factor in this growth. With the rise of smart factories and IoT technologies, there's an escalating requirement for components that facilitate precise control over fluid dynamics. Moreover, the transition towards more sustainable technologies has propelled industries to adopt solenoid valves for their energy efficiency and reliability. A report by Research and Markets also highlighted that the Asia-Pacific region is a hotbed for this growth, fueled by rapid industrialization and increased investments in infrastructure development.

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs - Analyzing Market Trends: The Growth of the Solenoid Valve Industry in Recent Years

| Year | Market Size (Million USD) | Growth Rate (%) | Key Applications | Trends |

|---|---|---|---|---|

| 2019 | 1500 | 5.0 | Automotive, HVAC | Increased automation and energy efficiency |

| 2020 | 1580 | 5.3 | Water Management, Oil & Gas | Shift towards renewable energy sources |

| 2021 | 1665 | 5.4 | Food & Beverage, Pharmaceutical | Focus on safety and hygiene |

| 2022 | 1750 | 5.1 | Industrial Automation, Aerospace | Adoption of IoT technologies |

| 2023 | 1850 | 5.7 | Environmental Control, HVAC | Sustainability initiatives |

Evaluating Distributor Performance: Metrics for Success in Solenoid Valve Supply Chain

When evaluating distributor performance in the solenoid valve supply chain, several key metrics can be utilized to ensure that suppliers meet organizational needs efficiently. One essential metric is the reliability of the supply chain, which can be informed by understanding how well distributors manage their inventory and forecast demand. In light of recent supply chain disruptions due to fluctuating oil prices and COVID-19, reliability becomes pivotal for companies looking to maintain operations without interruption.

Moreover, the ability of distributors to implement multi-region sourcing strategies is crucial. These strategies can provide companies with greater flexibility and mitigate risks associated with local disruptions. A focused assessment of a distributor's sourcing capabilities, including their network of suppliers and local manufacturing practices, can illuminate their preparedness for unexpected market changes. By investing in comprehensive evaluation frameworks, organizations can better position themselves to select solenoid valve distributors who not only deliver quality products but also contribute to a more resilient and responsive supply chain.

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries