How to Choose the Right Norgren Valves for Your Applications?

Choosing the right Norgren valves for your specific applications is crucial. Industry expert John Smith stated, "Selecting the right valve can enhance efficiency." His insights remind us that the right choice can significantly impact performance and reliability.

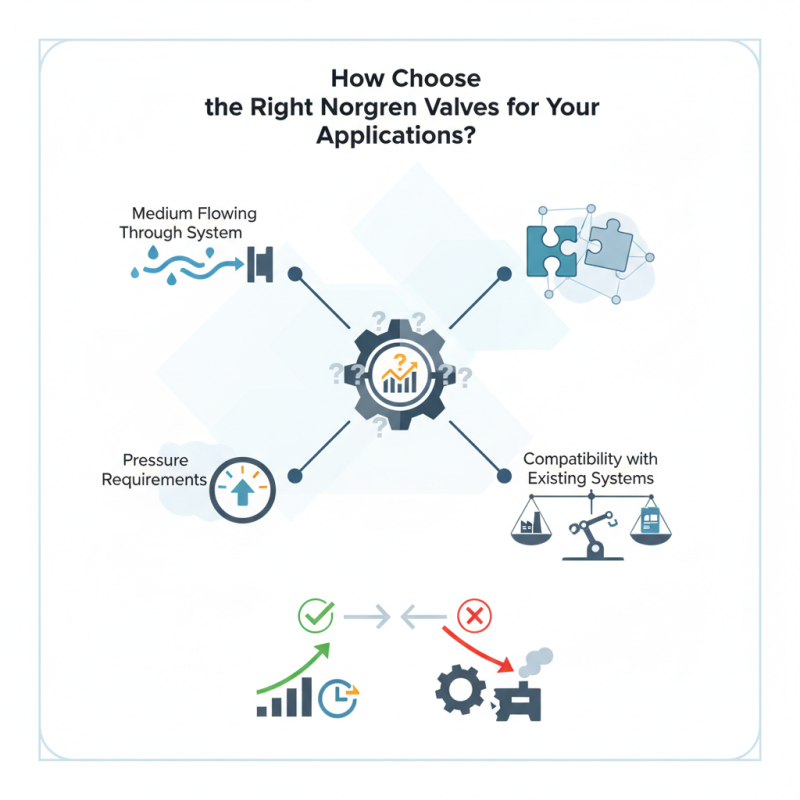

There are many factors to consider. You must evaluate the medium flowing through the system. Pressure requirements also play a vital role. Moreover, ensuring compatibility with existing systems is vital. Many overlook these details, leading to costly mistakes and inefficiencies.

When faced with various options, it can feel overwhelming. Not all Norgren valves are the same, and making the wrong choice can hinder operations. Reflecting on these aspects helps in making a more informed decision. Always remember: the right valve is not just about brand, but about suitability for purpose.

Factors to Consider When Choosing Norgren Valves

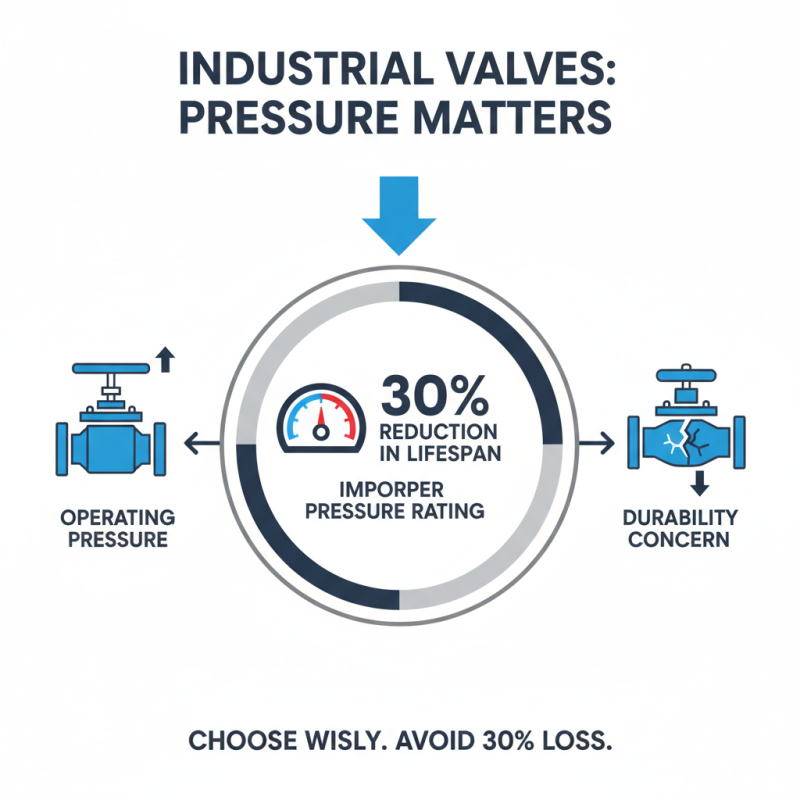

Choosing the right valves is vital for industrial applications. The first factor to consider is the operating pressure. Valves must operate efficiently within their designated pressure range. Reports indicate that improper pressure ratings can lead to 30% reduced lifespan. This is a significant concern for industries relying on durability.

Another critical factor is the medium being controlled. Fluids can vary greatly in temperature, viscosity, and chemical composition. For instance, corrosive substances require valves made from specific materials. A study found that 25% of valve failures stem from material incompatibility. Users must ensure the valve's material aligns with the application.

Lastly, consider the control method. Pneumatic, hydraulic, or manual actuation can greatly influence performance. Some users gravitate toward user-friendliness, while others prioritize precision. However, many overlook the need for appropriate sizing. Oversized valves can lead to inefficiencies, while undersized ones can restrict flow. Reflecting on these choices can lead to improved operational performance.

Types of Norgren Valves and Their Applications

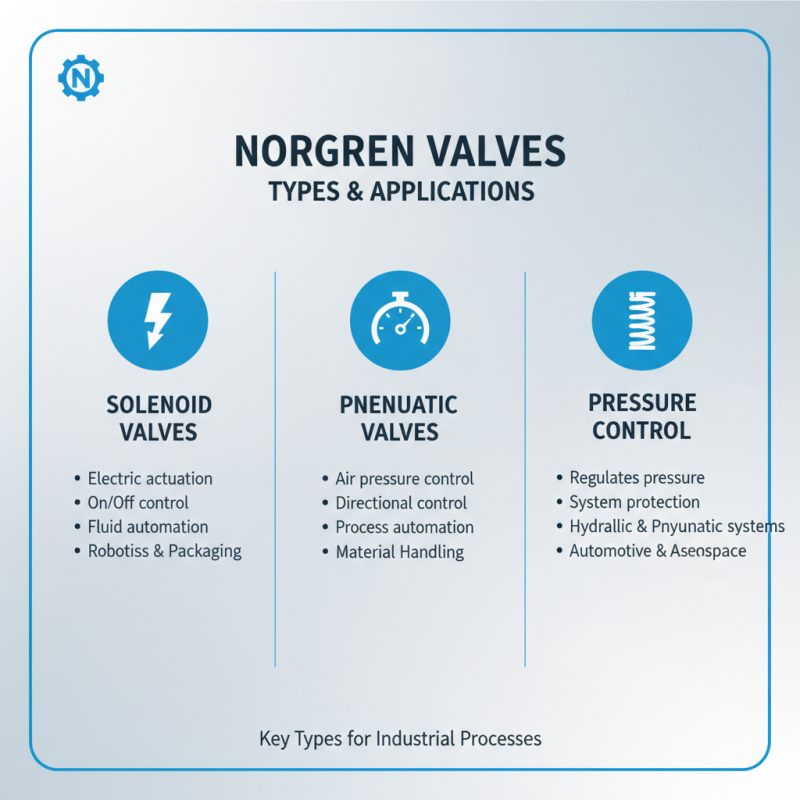

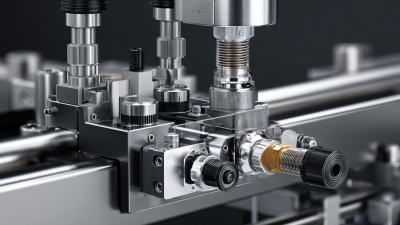

When selecting Norgren valves, understanding their types and applications is crucial. Different valve types serve unique purposes. Common types include solenoid valves, pneumatic valves, and pressure control valves. Each type plays a critical role in various industrial processes.

For instance, solenoid valves are often used in automation systems. They enable precise control over fluid movement. Data indicates that over 30% of industrial automation systems utilize solenoid valves due to their efficiency. Pneumatic valves, on the other hand, are essential in controlling air-powered machinery. A report states that they account for nearly 25% of all valve usage in manufacturing sectors.

Pressure control valves are vital in maintaining system integrity. They help regulate pressure in hydraulic systems. Improper selection can lead to system failures. It is estimated that a staggering 15% of operational downtime is linked to valve failure. This emphasizes the need for careful consideration in the selection process. Ensure that each valve chosen matches the specific demands of your application. Understanding the unique characteristics of each type is key to mitigating risks.

Understanding Technical Specifications for Valve Selection

When selecting valves for your applications, understanding technical specifications is crucial. Each valve has unique features. These characteristics can determine their efficiency and longevity. Focus on key specifications like pressure rating, flow capacity, and valve type. These factors often dictate suitability for specific tasks.

Pressure ratings indicate the limits within which a valve operates. Exceeding these ratings can lead to failures or inefficiency. Similarly, flow capacity measures how much fluid a valve can manage. Ensure that the chosen valve aligns with the system’s requirements. Neglecting this could result in inadequate performance, impacting the entire operation.

Valve type is equally significant. Different types serve various functions. Misreading specifications can lead to selecting the wrong type. This mistake can hinder productivity and increase costs. It’s essential to thoroughly review the specifications available. Sometimes, specifications can be overly technical. Take your time understanding them. Seek clarification when needed. This approach ultimately leads to better selections.

Common Issues in Valve Selection and How to Avoid Them

Choosing the right valves can be challenging. Many factors can complicate the selection process. One common issue is misunderstanding the application requirements. For example, pressure ratings and flow characteristics must align with system needs. Ignoring these can lead to system failures.

Another concern is material compatibility. Selecting valves made from unsuitable materials can cause corrosion or damage. Always consider the media that will flow through the valve. For instance, a valve used for corrosive substances needs to withstand harsh conditions. This detail is often overlooked but crucial for maintaining system integrity.

Lastly, many users forget to consider maintenance and replacement parts. Valves require upkeep to function correctly. A valve that seems perfect now might be a hassle later if maintenance is difficult. Choose valves with accessible parts and clear maintenance guidelines. Making informed choices today can prevent costly issues tomorrow.

Performance Comparison of Valve Types for Industrial Applications

Best Practices for Installing and Maintaining Norgren Valves

When installing valves, attention to detail is crucial. Proper alignment helps prevent leaks and ensures smooth operation. Misalignment can cause wear and tear. Always refer to the installation guidelines provided. This step is sometimes overlooked but crucial for optimal performance.

Regular maintenance is essential for longevity. Inspect valves for any signs of wear, corrosion, or damage. Replace seals as needed. Clean components regularly to avoid buildup that could hinder performance. Neglecting maintenance can lead to breakdowns, resulting in costly repairs.

Tip: Use appropriate lubricants to minimize friction in moving parts. This can also enhance the lifespan of your valves. Remember to calibrate your valves periodically. This check helps maintain accuracy and efficiency in your system. Small adjustments can lead to significant improvements. Regular checks might seem tedious, but they pay off in the long run.

Related Posts

-

How to Choose Norgren Valves for Your Applications?

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

What is a Pneumatic System and How Does It Work?

-

Exploring the Future of Machine Vision Technologies in 2025 Top Applications

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries