How to Choose the Right Pneumatic Solenoid Valve for Your Application?

Choosing the right pneumatic solenoid valve for your application can be challenging. With numerous options available, making a decision may feel overwhelming. Each valve has unique characteristics and specifications that can affect its performance.

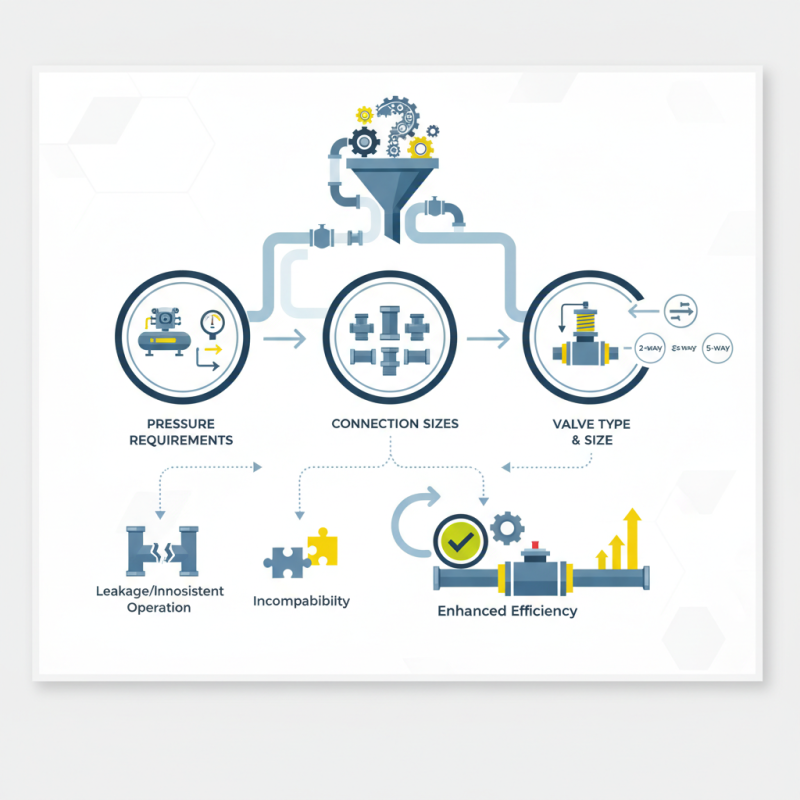

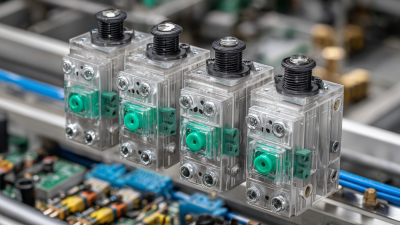

A pneumatic solenoid valve controls the flow of air in various systems. It is essential to understand the different types and sizes that suit your needs. Consider the pressure requirements and connection sizes carefully. Sometimes, users find themselves unsure about the compatibility of their equipment. It’s common to overlook important criteria, leading to inefficiency.

In some cases, individuals end up selecting a valve that doesn't fit their system perfectly. This can cause issues like leakage or inconsistent operation. Reflecting on these choices is crucial. It's vital to gather all relevant information before making a final decision. A well-informed choice can enhance the efficiency of your operation.

Understanding Pneumatic Solenoid Valves: Types and Functions

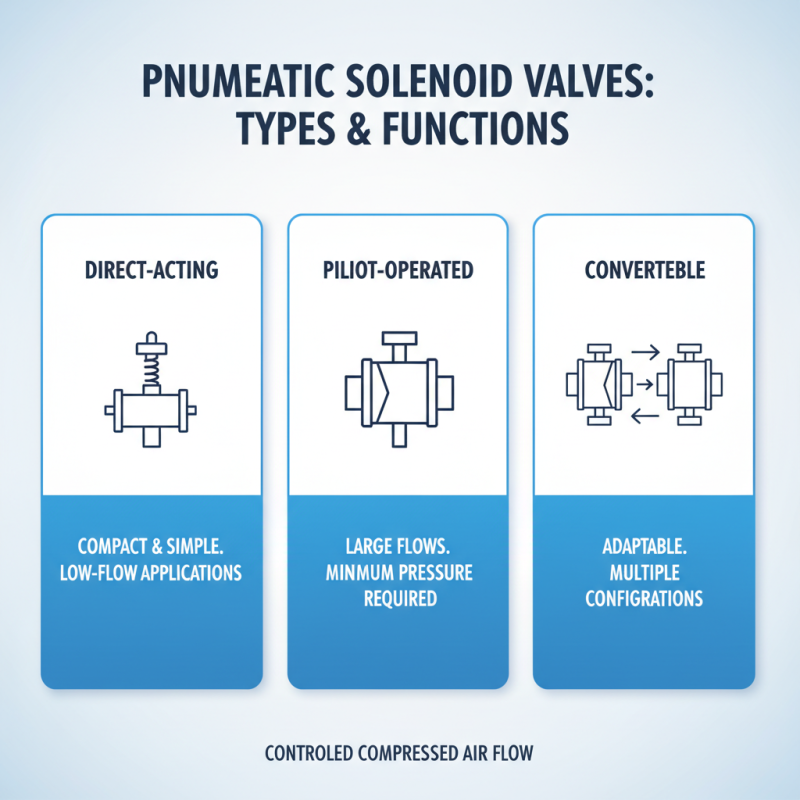

Pneumatic solenoid valves play a vital role in various industries. They control the flow of compressed air. Understanding their types and functions is essential for selecting the right one. These valves are categorized into direct-acting, pilot-operated, and convertible types. Direct-acting valves are compact and simple, making them ideal for low-flow applications. Pilot-operated valves handle larger flows but require a minimum pressure.

According to a recent industry report, the global pneumatic valve market is expected to grow significantly. It is projected to reach USD 12 billion by 2025. This growth reflects increasing automation in manufacturing. Selecting the correct valve impacts system efficiency and operational costs. Improper choices can lead to malfunctions. Misalignment of valve specifications with application needs can cause downtime.

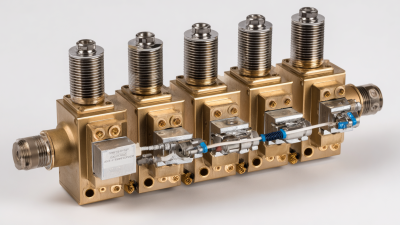

It's crucial to examine the actuator type as well. Electromagnetic or mechanical options can affect performance. The choice of materials also plays a key role in durability. For instance, corrosion-resistant materials increase lifespan. Many users overlook these details, which can lead to costly errors. Understanding the full scope of pneumatic solenoid valves will enhance functionality and reliability.

Key Factors in Selecting Pneumatic Solenoid Valves for Specific Applications

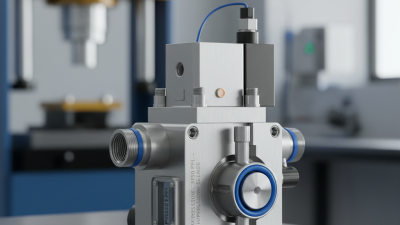

When selecting pneumatic solenoid valves for specific applications, several factors require careful consideration. Pressure ratings are crucial. Many industrial applications operate under varying pressure conditions. According to a recent industry report, nearly 40% of valve failures stem from incorrect pressure ratings. Ensuring alignment with system requirements can save costs and prevent downtime.

Another key factor is the medium. Valves handle gases and liquids differently. For instance, corrosive chemicals demand specific materials, while high-pressure air applications might need robust designs. A 2023 survey indicated that over 25% of valve users report issues related to medium incompatibility. Understanding the characteristics of the fluid or gas is essential for optimal performance.

Lastly, the valve's response time can significantly impact operations. In processes needing quick actuation, slower valves may lead to inefficiencies. An older study showed that 60% of manufacturing delays were due to outdated valve technology. Assess not just the specifications but also the application environment to ensure proper integration. A comprehensive approach leads to more reliable use and fewer operational hiccups.

Evaluating Performance Metrics: Flow Rate and Pressure Ratings

When selecting a pneumatic solenoid valve, evaluating performance metrics is essential.

Flow rate is one of the most critical factors.

It determines how much air can pass through the valve in a specific timeframe. Too low a flow rate may lead to insufficient actuation.

Conversely, an excessively high flow rate could waste resources and impact system efficiency.

Finding a balance is crucial for optimal function.

Pressure ratings also play a significant role in valve selection.

The valve must withstand the system's maximum pressure without failing.

If the pressure rating is too low, it can lead to dangerous leaks or valve failure.

A thorough assessment of your application's pressure requirements is vital.

Consider variations in pressure during operation. It's common to overlook these changes, but they can significantly affect performance.

Reflecting on these metrics should lead to better decision-making.

Testing different valves in real-world scenarios might reveal unexpected results.

Engineers often rely on specifications, yet practical applications can vary.

A seemingly perfect valve could perform poorly in actual conditions.

Regular evaluations and adjustments are necessary for achieving reliable results.

Material Compatibility and Environmental Considerations in Valve Selection

Choosing the right pneumatic solenoid valve requires careful consideration of material compatibility. Different fluids and gases react differently with various materials. For instance, aggressive chemicals may degrade certain plastics. Similarly, high temperatures can compromise rubber seals. Understanding the specific requirements of your application is essential.

Environmental factors also play a significant role in valve selection. Will the valve face extreme temperatures or fluctuations? Is it exposed to dust, moisture, or corrosive substances? These conditions can affect the valve's performance and lifespan. Using a valve that can't withstand environmental demands may lead to frequent failures.

Sometimes, users overlook minor details that lead to significant issues. A brightly colored valve may seem appealing, but if the material isn't appropriate, it could fail when needed most. It's vital to revisit these choices and consult with experts when necessary. Failing to address material compatibility and environmental concerns could result in costly downtime and repairs. Always reflect on the specifics of your application to ensure optimal performance.

Maintenance and Lifespan: Ensuring Optimal Performance of Solenoid Valves

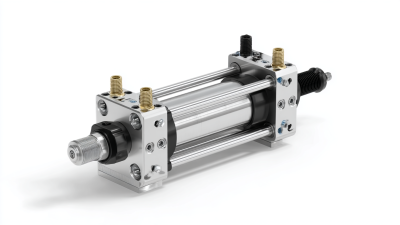

Maintaining pneumatic solenoid valves is crucial for their longevity and efficiency. Regular inspection can help identify wear and tear early. Check for leaks and unusual noises during operation. Often, simple maintenance can prevent bigger issues down the line. Cleaning the valve and its components ensures smooth operation. Dust and debris can hinder performance, so a clean environment is essential.

The lifespan of solenoid valves varies widely. Factors include the application, environment, and frequency of use. High-demand environments may reduce valve longevity. It's essential to understand the conditions in which your valve operates. Monitor performance regularly to catch any signs of decline.

Timing is key; waiting too long can lead to failure. Consider setting a maintenance schedule based on usage patterns. By focusing on these aspects, you can ensure your pneumatic solenoid valves perform optimally for longer.

Related Posts

-

Top 10 Solenoid Valve Distributors: Find the Best Suppliers Near You

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries