2026 How to Choose a Pneumatic Actuator Solenoid Valve Effectively?

In the world of industrial automation, choosing the right pneumatic actuator solenoid valve is crucial. According to a recent report by the International Society of Automation, improper valve selection can lead to operational inefficiencies costing companies nearly 15% in lost productivity. Such statistics highlight the importance of making informed decisions in this area.

John Smith, a leading expert in fluid control systems, emphasizes, "The relevance of a tailored approach in selecting pneumatic actuator solenoid valves cannot be overstated.” His insights reflect the need for careful evaluation of specific application requirements. Each pneumatic actuator solenoid valve operates uniquely within different systems, making it vital to consider factors like pressure rating, response time, and material compatibility.

Inadequate attention to these elements can lead to failure or suboptimal performance. Many engineers overlook nuanced specifications, assuming one valve fits all. This misconception can create significant challenges in the long run. A deeper understanding of the functionalities of pneumatic actuator solenoid valves is essential for improved reliability and efficiency in automation processes.

Understanding Pneumatic Actuators: Types and Applications in Industry

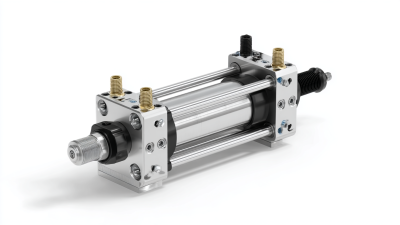

Pneumatic actuators play a vital role in various industrial applications. They convert compressed air into mechanical motion. This motion can control valves, dampers, and other devices. Understanding different types of pneumatic actuators is crucial for effective use. There are linear and rotary actuators. Linear actuators move in a straight line, while rotary actuators provide circular motion.

Each actuator type has distinct applications. Linear actuators are commonly used in automation systems. They offer precise positioning. Rotary actuators suit applications needing torque. Examples include conveyor systems and robotics. In many cases, the choice isn’t straightforward. Factors like pressure, load, and speed affect performance.

Selecting the right actuator type demands careful thought. Each option has its pros and cons. A mismatched actuator may lead to inefficiencies. Consider the environment too. Some actuators may not withstand extreme temperatures. Reflecting on these details can save time and money. The process is not always easy, but informed decisions yield better outcomes.

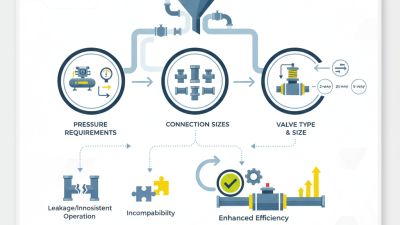

Key Factors Influencing the Selection of Solenoid Valves for Pneumatic Systems

When selecting a solenoid valve for pneumatic systems, several key factors come into play. These factors significantly influence performance and efficiency. One vital aspect is the valve size. Ensure the valve matches the system's flow requirements. An oversized valve may lead to inefficiencies. Conversely, a small valve can restrict flow.

Pressure rating is another critical factor in the selection process. The valve must withstand the system's operational pressure. A mismatch could result in leaks or failures. Additionally, consider the environment. Extreme temperatures or corrosive conditions can impact valve longevity.

Tips: Check if the valve material is suitable for your application. Regular maintenance helps avoid unexpected issues. Make sure to evaluate the response time. A slow response can affect system performance. With these considerations, you'll enhance your system’s functionality and reliability.

Evaluating Performance Metrics: Pressure, Flow Rate, and Response Time

When selecting a pneumatic actuator solenoid valve, three performance metrics stand out: pressure, flow rate, and response time. Pressure is crucial. High-pressure applications require valves that can withstand elevated levels without leakage. If the valve fails under pressure, it compromises the entire system. Always assess the maximum and minimum operational pressures.

Flow rate is another significant factor. It determines how quickly fluid can move through the valve. A low flow rate can hinder operations. It’s vital to select a valve that meets the specific needs of your application. Ensuring compatibility with required flow rates can prevent bottlenecks.

Response time shouldn't be overlooked. This metric assesses how quickly the valve can open or close. A delay in response can lead to inefficiencies. Testing the response in real conditions can reveal unexpected delays. It’s common to discover that manufacturer's claims don't always align with actual performance. Evaluating these metrics carefully helps in making an informed choice.

2026 How to Choose a Pneumatic Actuator Solenoid Valve Effectively? - Evaluating Performance Metrics: Pressure, Flow Rate, and Response Time

| Valve Type | Max Pressure (bar) | Flow Rate (L/min) | Response Time (ms) | Temperature Range (°C) |

|---|---|---|---|---|

| Type A | 8 | 250 | 50 | -20 to 80 |

| Type B | 12 | 300 | 30 | -10 to 90 |

| Type C | 16 | 400 | 20 | -30 to 100 |

| Type D | 10 | 200 | 40 | -15 to 85 |

| Type E | 14 | 350 | 25 | -25 to 95 |

Material Compatibility and Environmental Considerations for Valves

Choosing the right pneumatic actuator solenoid valve

involves careful consideration of materials and environmental factors.

Material compatibility is crucial. Not all materials withstand harsh conditions. For example, metals like

stainless steel resist corrosion, while plastics may degrade in UV exposure.

Assess the chemicals in use. Check for compatibility with valve materials.

Many users overlook environmental factors.

Temperature extremes affect valve performance. High temperatures can

cause seals to wear out quickly. Cold conditions may lead to freezing fluids, impacting functionality. Aim for valves

rated for your specific environment. This ensures reliability and longevity in operations.

Tips:

Always test materials in real-world conditions. Consider the potential for unexpected reactions.

Don’t rely solely on specs. Mistakes can lead to costly downtime. Regularly inspect and maintain valves. Small issues

may grow into bigger problems. Clear documentation of your environment and material choices can simplify future decisions.

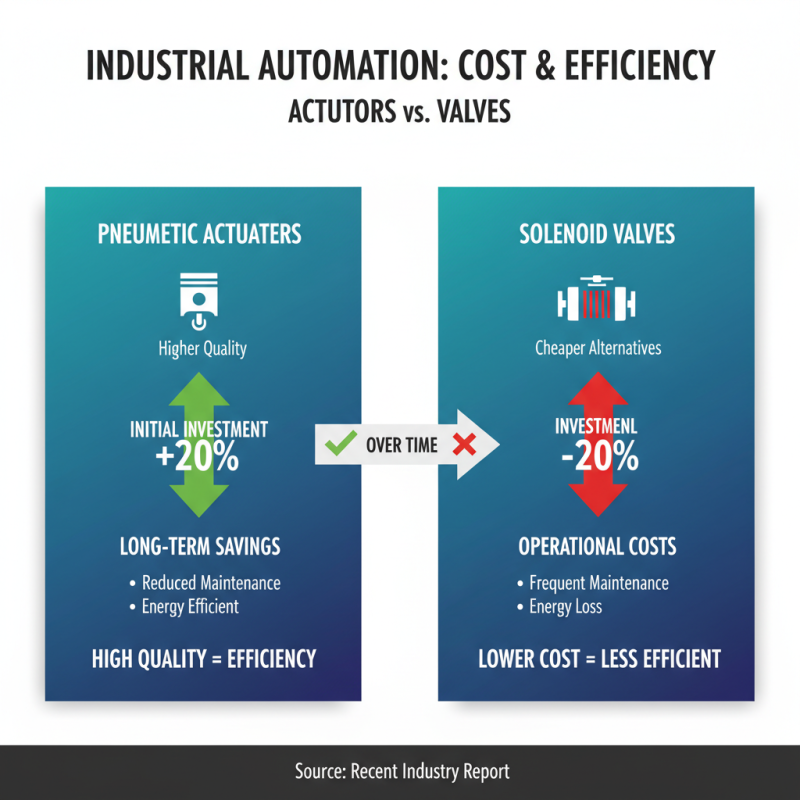

Cost-Benefit Analysis: Initial Investment vs. Long-Term Efficiency in Actuators

In the field of industrial automation, the choice of pneumatic actuators and solenoid valves significantly impacts both costs and efficiency. Analyzing the initial investment versus long-term operational efficiency is vital. According to a recent industry report, an initial investment in high-quality pneumatic actuators can rise by 20% compared to cheaper alternatives. However, this upfront cost is often offset by the long-term savings in maintenance and energy efficiency.

Consider that well-designed pneumatic actuators can offer efficiencies ranging from 75% to 90%. In contrast, lower-end models may only achieve 60% efficiency. This means your choice will influence energy consumption and operating costs for years. Over a decade, energy savings alone can exceed initial costs by 30-50%. Yet, many companies overlook these calculations, focusing solely on the upfront price.

Predicting maintenance costs is equally crucial. Many businesses report that a cheaper actuator requires twice the maintenance of a premium model. This reality pushes some to reconsider their choices. Investing in higher-quality components might seem daunting, but failing to do so could lead to increased downtime and unplanned expenses. Balancing initial costs with long-term efficiency is a nuanced process that requires careful thought.

Related Posts

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

-

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

-

Top 10 Solenoid Valve Distributors: Find the Best Suppliers Near You

-

How to Choose the Right Pneumatic Solenoid Valve for Your Application?

-

2026 Best Solenoid Valve Distributors to Consider?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries