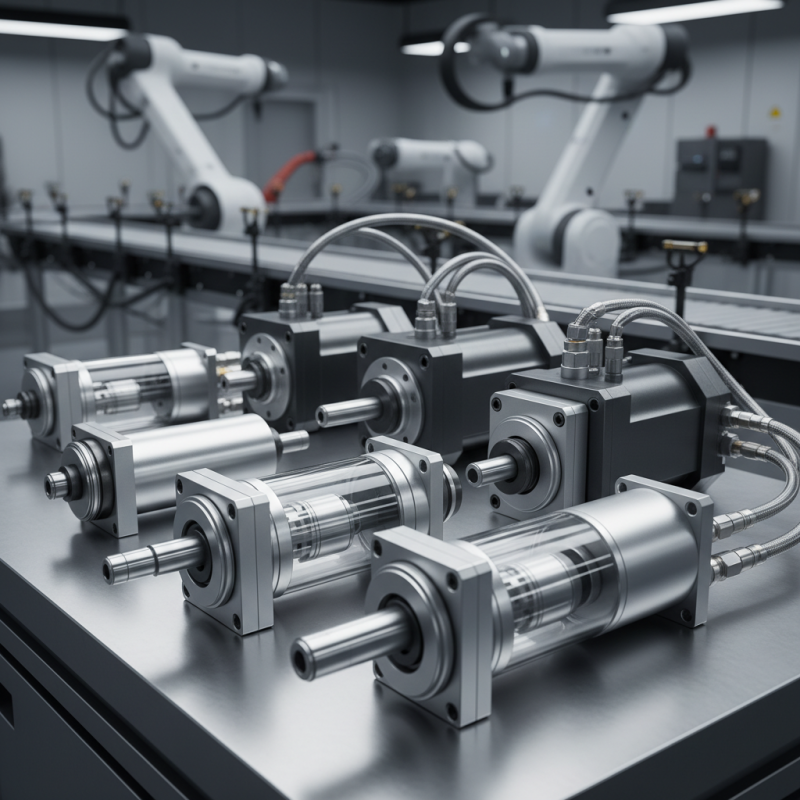

Best Pneumatic Actuators for Optimal Performance and Efficiency?

Pneumatic actuators play a crucial role in various industries, driving efficiency and performance. According to a recent report by MarketsandMarkets, the global pneumatic actuator market is projected to reach $6.34 billion by 2026, growing at a CAGR of 5.3%. This highlights the increasing reliance on pneumatic actuators in sectors such as manufacturing, automotive, and food processing.

Modern pneumatic actuators offer advantages such as speed and precision. They are often preferred for their swift response times, making them ideal for time-sensitive operations. However, not all pneumatic actuators perform equally. Factors such as material composition and design intricacies can significantly impact their effectiveness. For instance, actuators made with lightweight metals may outperform standard models in specific applications but can lack durability.

It’s essential to continually assess the operational efficiency of pneumatic actuators. Industry data suggests that improper selection can lead to increased downtime and maintenance costs. Organizations must carefully analyze their requirements to avoid common pitfalls. While many pneumatic actuators are designed for optimal performance, the best choice will depend on unique operational needs and environments.

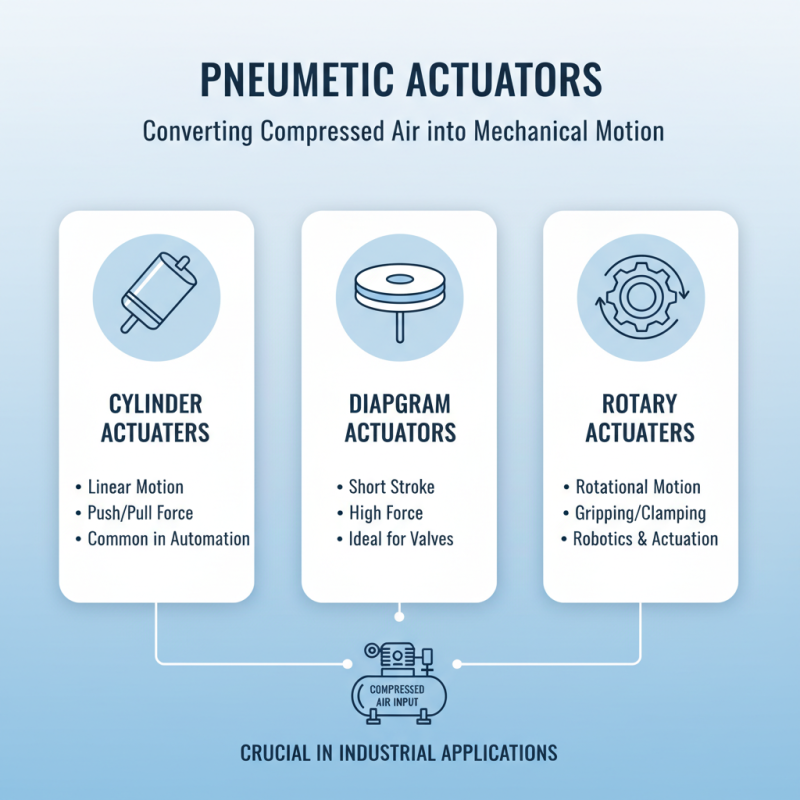

Types of Pneumatic Actuators and Their Applications

Pneumatic actuators are crucial in many industrial applications. They convert compressed air into mechanical motion. There are several types, including cylinder actuators, diaphragm actuators, and rotary actuators. Each type has unique advantages tailored to specific tasks.

Cylinder actuators are commonly used for linear motion. They are found in packaging, food processing, and assembly lines. According to industry reports, their efficiency can reach 90%. However, they require consistent maintenance. Neglecting them can lead to air leaks and reduced performance.

Diaphragm actuators are often used in valve control. They provide precise control in fluid handling applications. However, their sensitivity to pressure changes can sometimes lead to erratic performance. It's essential to monitor the pressure levels closely to ensure smooth operation.

**Tips**: Regularly check for air leaks. Even minor leaks can significantly impact efficiency. Ensure that all connections are tight. Use filters to prevent contamination in the air supply. This can enhance the lifespan of your actuators.

In contrast, rotary actuators enable rotational motion. They are ideal for applications like conveyor systems. Their simplicity makes them easy to integrate, but they may lack precision in some scenarios. Understand the application's specific requirements to choose the right actuator type effectively.

Factors Influencing Performance and Efficiency of Pneumatic Actuators

Pneumatic actuators are vital in various industries. Their performance and efficiency hinge on several key factors. The first factor is pressure regulation. According to industry reports, maintaining optimal pressure within the actuator can enhance efficiency by up to 30%. However, fluctuations in pressure can lead to response delays or inefficient motion.

Another crucial aspect is the actuator's design. The geometry impacts flow rates and response times. A well-designed actuator allows for smoother operations. It can achieve higher speeds with less energy. Some studies indicate that even minor design enhancements can improve energy efficiency by 15%. Yet, many engineers still overlook the importance of meticulous design evaluations, often leading to unforeseen inefficiencies.

Moreover, the supply and quality of compressed air play significant roles. Contaminated air can degrade actuator performance. It might lead to increased wear or failures. Research suggests that using clean, dry air can extend actuator life by over 20%. Still, many facilities do not prioritize proper air filtration. This negligence can result in higher maintenance costs down the line.

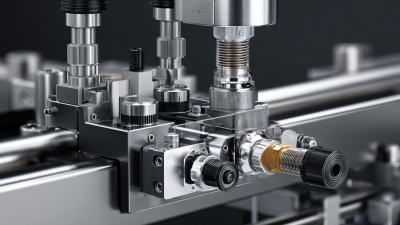

Key Features to Consider When Selecting Pneumatic Actuators

When selecting pneumatic actuators, several key features are crucial for ensuring optimal performance. One important factor is the actuator’s size and type. Compact actuators are ideal for limited spaces. Larger ones offer more force but may not fit everywhere. Another aspect to consider is the stroke length. A longer stroke allows for greater movement, but precision is sometimes sacrificed.

Next, examine the materials used in the actuator's construction. Corrosion-resistant materials are vital in harsh environments. They enhance longevity and reduce maintenance needs. Furthermore, the actuator's response time is often overlooked. Fast response times lead to improved efficiency in process control. However, if the response is too quick, it could cause instability in the system.

Installation and compatibility are other critical considerations. Ensure the actuator fits your existing systems. Poor compatibility can lead to inefficient operations. Additionally, think about the energy requirements. Some actuators consume more air than others, affecting overall efficiency. It’s essential to balance performance with energy consumption for optimal results.

Performance Comparison of Pneumatic Actuators

This chart compares the efficiency and performance scores of various pneumatic actuators. Actuator D shows the highest efficiency and performance score, making it an optimal choice for applications requiring superior performance.

Comparative Analysis of Leading Pneumatic Actuator Brands

When it comes to pneumatic actuators, efficiency and performance are critical. Various brands have emerged, each claiming superiority. However, a comparative analysis shows nuanced differences. A recent industry report indicates that pneumatic actuators can increase operational efficiency by up to 30% in specific applications. Yet, actual performance varies widely among brands.

One noteworthy aspect is the materials used. Some actuators employ aluminum, while others opt for composite materials. Durability is often compromised in lighter models. The coefficient of friction can also influence performance significantly. This is evident in tests that show a range of 0.05 to 0.15 for different actuator brands. These variations can affect how quickly and effectively an actuator responds.

Maintenance frequency is another critical concern. A well-documented study found that certain actuators require up to 15% more maintenance. This impacts both operation costs and downtime. Users often overlook these details during selection, leading to unintended consequences. The decision should consider not just performance, but total cost of ownership, including potential maintenance issues. Ultimately, understanding these factors deepens insights into selecting the best pneumatic actuator for various applications.

Best Pneumatic Actuators for Optimal Performance and Efficiency

| Actuator Type | Max Pressure (psi) | Stroke Length (inches) | Material | Efficiency Rating | Weight (lbs) |

|---|---|---|---|---|---|

| Double Acting | 120 | 4 | Aluminum | 90% | 8.5 |

| Single Acting | 100 | 3 | Stainless Steel | 85% | 5.5 |

| Rotary Actuator | 150 | 2 | Brass | 88% | 6.2 |

| Compact Actuator | 80 | 1.5 | Polymer | 92% | 4.3 |

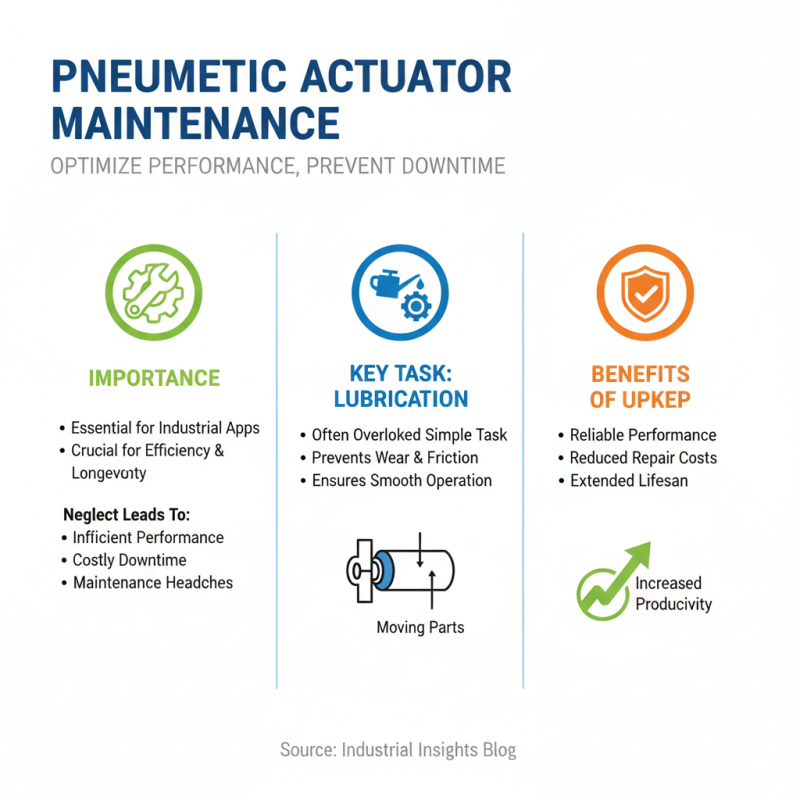

Maintenance Best Practices for Enhanced Actuator Performance

Pneumatic actuators are essential for many industrial applications. To ensure they operate effectively, regular maintenance is crucial. A neglected actuator can lead to inefficient performance, costly downtimes, and a headache for maintenance teams. Often, the simplest tasks, like lubricating moving parts, can be overlooked. This may seem minor, but it plays a pivotal role in preventing wear.

Checking for air leaks is another vital step. Even small leaks can cause significant loss of efficiency. Identifying these leaks requires diligent observation. Sometimes, they go unnoticed until the actuator fails. It's wise to conduct routine inspections. Pay attention to the seals and fittings, as these areas are prone to degradation.

Training personnel on maintenance practices is essential. Employees should understand the importance of these tasks. Even well-trained teams can miss critical checks. Scheduling regular maintenance sessions can help instill this culture. Consistent attention can translate into enhanced performance and fewer breakdowns. Balancing efficiency with diligence is a challenge, but it's vital for actuator longevity.

Related Posts

-

How to Choose the Right Air Cylinder for Your Application

-

Top Benefits of Using Air Cylinders in Industrial Applications

-

How to Choose the Right Pneumatic Solenoid for Your Automation Needs

-

How to Choose the Right Pneumatic Air Cylinder for Your Application

-

10 Essential Tips for Choosing the Right Air Solenoid for Your Needs

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries