Top 2025 Humphrey Air Valve Types: What You Need to Know for Optimal Performance

In the ever-evolving landscape of pneumatic control systems, understanding the various types of Humphrey air valves is crucial for achieving optimal performance in diverse applications. As noted by industry expert Dr. Sarah Jenkins, "The efficiency and reliability of a pneumatic system heavily depend on selecting the right air valve that matches the specific requirements of the task." In 2025, the market is increasingly offering innovative designs and technologies that enhance the functionalities of Humphrey air valves, catering to the growing demands of automation and precision in industries ranging from manufacturing to automotive.

As we delve into the top Humphrey air valve types, it is essential to consider their unique characteristics and operating principles. Each type of valve brings its advantages, influencing performance factors such as response time, flow rate, and operational longevity. Consequently, understanding these distinctions will empower engineers and technicians to make informed decisions that not only optimize system efficiency but also reduce maintenance costs and enhance overall productivity. In this outline, we aim to provide insights that will guide professionals in navigating the complexities of selecting the right Humphrey air valve for their specific application needs.

Key Features of Humphrey Air Valves for Enhanced Efficiency

When selecting air valves, understanding their key features is crucial for enhancing system efficiency. One important characteristic is the valve's response time, which can significantly impact performance, particularly in applications that require rapid actuation. A valve with a quick response time ensures that the system can adapt to changing demands promptly, reducing downtime and improving operational speed.

Another vital feature is the sealing capability of the air valve. High-quality seals minimize air leakage, which not only conserves energy but also sustains optimal pressure levels within system components. Additionally, a robust sealing mechanism can prolong the valve's lifespan by preventing contaminants from entering the system, thus reducing maintenance costs and downtimes.

Ease of installation and maintenance is also a significant factor to consider. Valves designed for simple integration into existing systems facilitate quicker setups and troubleshooting processes. Features such as modular design and accessible components allow for efficient replacements or repairs, ensuring that systems remain operational with minimal interruptions. With these elements in mind, selecting the right air valve can lead to improved efficiency and reliability in various applications.

Different Types of Humphrey Air Valves and Their Applications

Humphrey air valves are vital components in a variety of pneumatic systems, allowing for the controlled regulation of air flow and pressure. These valves come in several configurations, each tailored to specific applications. For instance, poppet valves, known for their simplicity and reliability, are often utilized in low-pressure systems where air flow needs to be quickly activated or deactivated. Their design minimizes the risk of leakage and wear, making them ideal for use in environments with strict maintenance requirements.

Another type is the solenoid valve, which is widely employed in automated systems. These valves use electromagnetic coils to control the opening and closing of the air flow, providing precise control that is essential for applications like robotics and packaging machinery. Additionally, the angle seat valve offers a compact design with a high flow capacity, making it suitable for high-pressure applications in industries such as automotive and manufacturing. Understanding the unique features and applications of these different valve types can significantly enhance system performance and efficiency, ultimately leading to better productivity and lower operational costs.

Selecting the Right Humphrey Air Valve for Your System Needs

When selecting the right air valve for your system, it's crucial to assess your specific operational requirements and environmental conditions. Different types of air valves are designed for various applications, so understanding the distinctions between these types will ensure optimal performance. Factors such as pressure ratings, flow capacity, and material compatibility play significant roles in the decision-making process. For instance, high-pressure applications may necessitate valves that can withstand greater stress, while corrosive environments might require materials that resist degradation.

Additionally, consider the purpose of the air valve within your system. Whether it's for controlling airflow, maintaining system pressure, or facilitating rapid exhaust, each application may dictate specific valve characteristics. Evaluating the installation requirements and available space can also influence your choice, as some valve types offer compact designs ideal for constrained spaces. Prioritizing these aspects will lead you to the most effective solution tailored to your system's unique needs, ensuring both reliability and efficiency in operation.

Maintenance Tips for Prolonging the Life of Humphrey Air Valves

To ensure optimal performance and longevity of air valves, regular maintenance is essential. One key aspect of upkeep is to keep the air valves clean and free from debris. Dust and contaminants can impair function and lead to premature wear. Implementing a routine cleaning schedule not only promotes efficiency but also prevents costly repairs in the future. Use a soft, damp cloth to wipe down the exterior and ensure that any ingress points remain unobstructed.

Another important tip for maintaining air valves involves checking for leaks at regular intervals. Even small leaks can dramatically affect the performance of the air system. A visual inspection alongside a pressure test can quickly identify potential issues. If you discover any leaks, address them immediately to prevent further damage and ensure the system runs smoothly.

Lastly, it’s crucial to lubricate moving parts periodically. Proper lubrication reduces friction and wear, significantly extending the life of the air valves. Utilize the manufacturer’s recommended lubricant and follow their guidelines for intervals and application methods. By prioritizing these essential maintenance practices, you can maximize the performance and durability of your air valves.

Performance Comparison of Different Air Valve Types

This chart displays the performance ratings of various types of air valves, ranging from Type A to Type E. Each type has been evaluated on a scale from 0 to 100, providing insights into their effectiveness and efficiency.

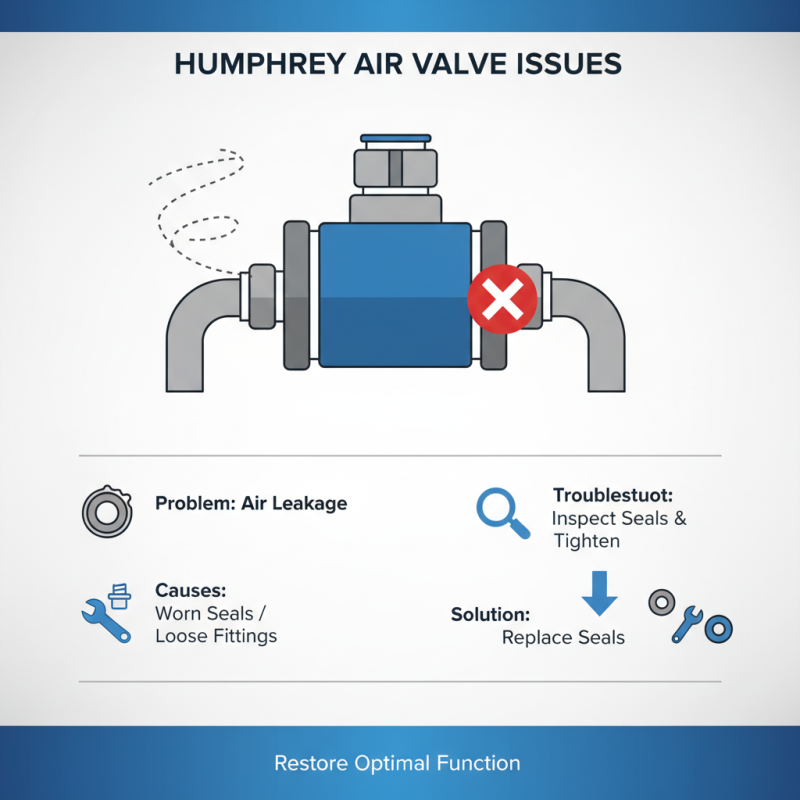

Common Issues with Humphrey Air Valves and Troubleshooting Solutions

Humphrey air valves are widely used in various applications, but like any mechanical system, they can encounter common issues that may hinder their performance. One frequently observed problem is air leakage, which can lead to inefficiency in operation. This issue often arises from worn-out seals or improper installation. To troubleshoot, first inspect the seals for any signs of damage and ensure that all fittings are tightened adequately. If leaks persist, replacing the seals may be necessary to restore optimal functionality.

Another common issue is valve sticking, which can occur due to dirt, dust, or corrosion buildup over time. This can result in delayed response times or complete failure to actuate. To address this, regular maintenance is crucial; cleaning the valve components using appropriate solvents can help remove debris. Additionally, lubricating moving parts with compatible greases can significantly enhance performance. In cases where the valve continues to stick despite cleaning, it may be necessary to disassemble the valve for a more thorough inspection and possible repair or replacement of affected components.

Related Posts

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

Top 10 Solenoid Valve Distributors: Find the Best Suppliers Near You

-

Top Benefits of Using Air Cylinders in Industrial Applications

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

How to Choose the Right Pneumatic Air Cylinder for Your Application

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries