Top 2026 Automatic Valve Types You Must Know About

In the world of industrial automation, understanding the different types of automatic valves is crucial. John Smith, a leading expert in valve technology, states, "Choosing the right automatic valve can save costs and increase efficiency." With innovations constantly reshaping the industry, it's essential to grasp the various designs and functionalities.

Automatic valves play a key role in fluid control systems. They enhance operational efficiency and minimize human error. However, many professionals still struggle to select the best option for their needs. There are various types available, each serving unique functions. Understanding these differences can be overwhelming, but it is essential for optimizing performance.

Investing in the right automatic valve type can yield significant benefits. However, overlooking details can lead to costly mistakes. It's crucial to weigh the pros and cons of each variant. Exploring their applications helps professionals make informed decisions. Embracing this complexity can lead to better outcomes in automation.

Overview of Automatic Valve Types and Their Applications

Automatic valves play a crucial role in various industries. They ensure proper flow control in systems, enhancing efficiency and safety. Common types include globe, ball, and butterfly valves. Each type serves distinct purposes. For example, ball valves are ideal for quick shut-off applications, while globe valves regulate flow effectively.

Many industries rely heavily on automated valve technology. According to a recent market research report by Fortune Business Insights, the global automatic valve market is projected to reach $24.3 billion by 2026. This growth stems from rising automation in manufacturing and increasing safety regulations in sectors such as oil and gas and water treatment. However, it's essential to stay updated on technological advancements. Failing to adapt may lead to inefficiencies in operations.

Tips: When selecting an automatic valve, consider compatibility with your system. Evaluate the materials used. Proper sizing is crucial for optimal performance. Regular maintenance is another aspect often overlooked. Neglecting it can result in costly downtime. Understanding these challenges helps organizations make informed decisions.

Top 2026 Automatic Valve Types and Their Applications

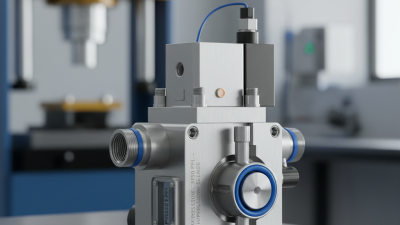

Ball Valves: Advantages and Usage in Fluid Control

Ball valves are essential in fluid control systems. Their design features a spherical disc, which allows for smooth flow. This simple, yet effective construction permits quick shut-off and precise regulation of fluids. Ball valves operate with a quarter-turn mechanism, making them easy to use. They can be adjusted quickly without much effort.

One major advantage of ball valves is their durability. They are often made from robust materials that resist corrosion. This makes them suitable for various environments, from residential to industrial applications. However, in certain conditions, they may not seal perfectly. This can lead to leaks if not properly maintained. Regular inspection is crucial to ensure long-term performance.

Another benefit is versatility. Ball valves can handle different types of media, including gases and liquids. They are used in plumbing, pipelines, and chemical processing. Choosing the right size is important to avoid flow issues. Sometimes, people overlook this detail, leading to inefficiencies. Proper sizing and regular maintenance are key to maximizing the benefits of ball valves.

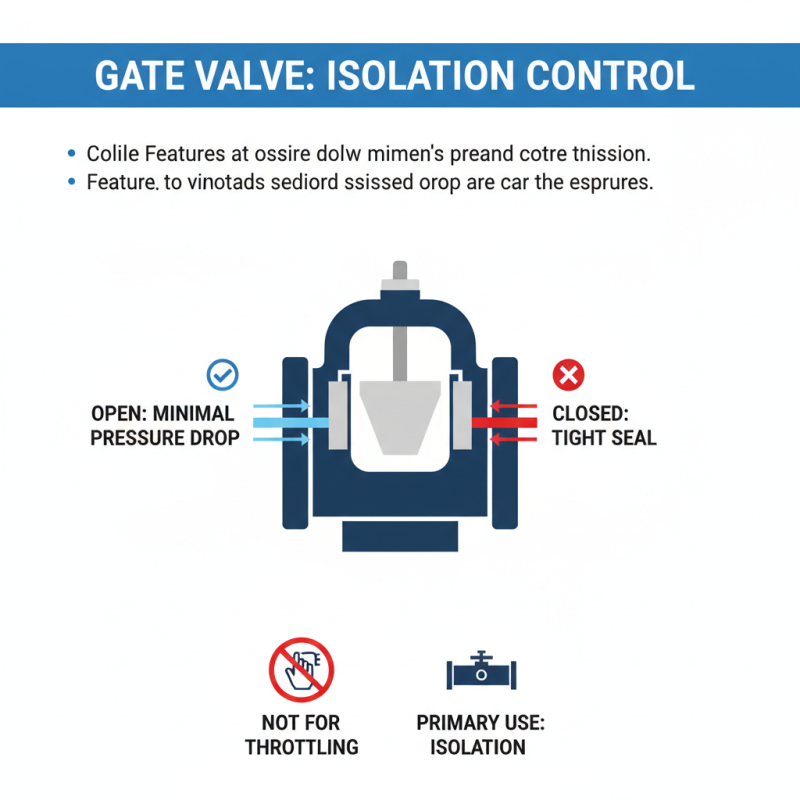

Gate Valves: Design Features and Common Utilization

Gate valves play a crucial role in various fluid systems. Their design features focus on providing reliable on-off control. Typically, they have a wedge-shaped disc that fits tightly against a seat. This design ensures minimal pressure drop when fully opened. It's essential to recognize that gate valves are not ideal for throttling. They are primarily used for isolation purposes.

Common utilization of gate valves includes pipelines, water treatment facilities, and industrial applications. They excel in situations where a straight-line flow is best. However, some might overlook maintenance issues. Over time, gate valves can experience wear and tear, leading to leaks. Proper inspection is vital to ensure their longevity.

In some cases, users may face challenges in valve selection. The size and material can significantly impact performance. Gate valves are often made of cast iron, stainless steel, or bronze. These materials offer differing levels of durability and corrosion resistance. While gate valves are effective, their limitations are worth considering. They may not always provide the best solution for every application, prompting further reflection on valve choice.

Check Valves: Functionality and Importance in Preventing Backflow

Check valves play a critical role in many industries, preventing backflow and protecting systems from damage. These valves only allow fluid to flow in one direction. According to the International Journal of Engineering Research, improper flow can lead to significant efficiency losses, sometimes up to 25%. Backflow can cause contamination in water systems, making check valves indispensable.

Many people overlook the importance of regular maintenance for check valves. Over time, sediment can accumulate, blocking the valve. It’s essential to inspect these valves periodically. A simple inspection can save thousands in repair costs. Remember to check for wear and tear as well.

Tip: Consider using a filter upstream to reduce sediment buildup. This can extend the life of your check valves. Monitoring pressure drops can also indicate issues with your valves. Regular maintenance checks can be a proactive measure. They help prevent serious problems before they escalate.

Butterfly Valves: Operational Mechanism and Industry Applications

Butterfly valves are essential in various industries. They utilize a rotating disk to regulate flow. This design allows for quick and efficient control. The operation is simple yet effective. When the disk is parallel to the flow, it opens fully. When it’s perpendicular, the flow is blocked. This straightforward mechanism minimizes pressure drop.

In water treatment plants, butterfly valves play a key role. They manage the flow of water efficiently. Their lightweight design makes installation easier. However, they may not seal perfectly under high-pressure conditions. Some operators find this a limitation. Regular maintenance is necessary to ensure optimal performance. When neglected, wear and tear can lead to failure.

These valves are also widely used in HVAC systems. They help control airflow in large buildings. This is crucial for energy efficiency. However, the choice of material can affect longevity. Some materials may corrode over time. Operators must frequently reassess their valve selections. Understanding these factors is critical for improved reliability and performance.

Related Posts

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

How to Choose the Right Air Cylinder for Your Application

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

-

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

-

Top 10 Tips for Choosing the Best Solenoid Valve Distributors for Your Needs

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries