2025 Top 5 Machine Vision Systems Revolutionizing Industry Automation

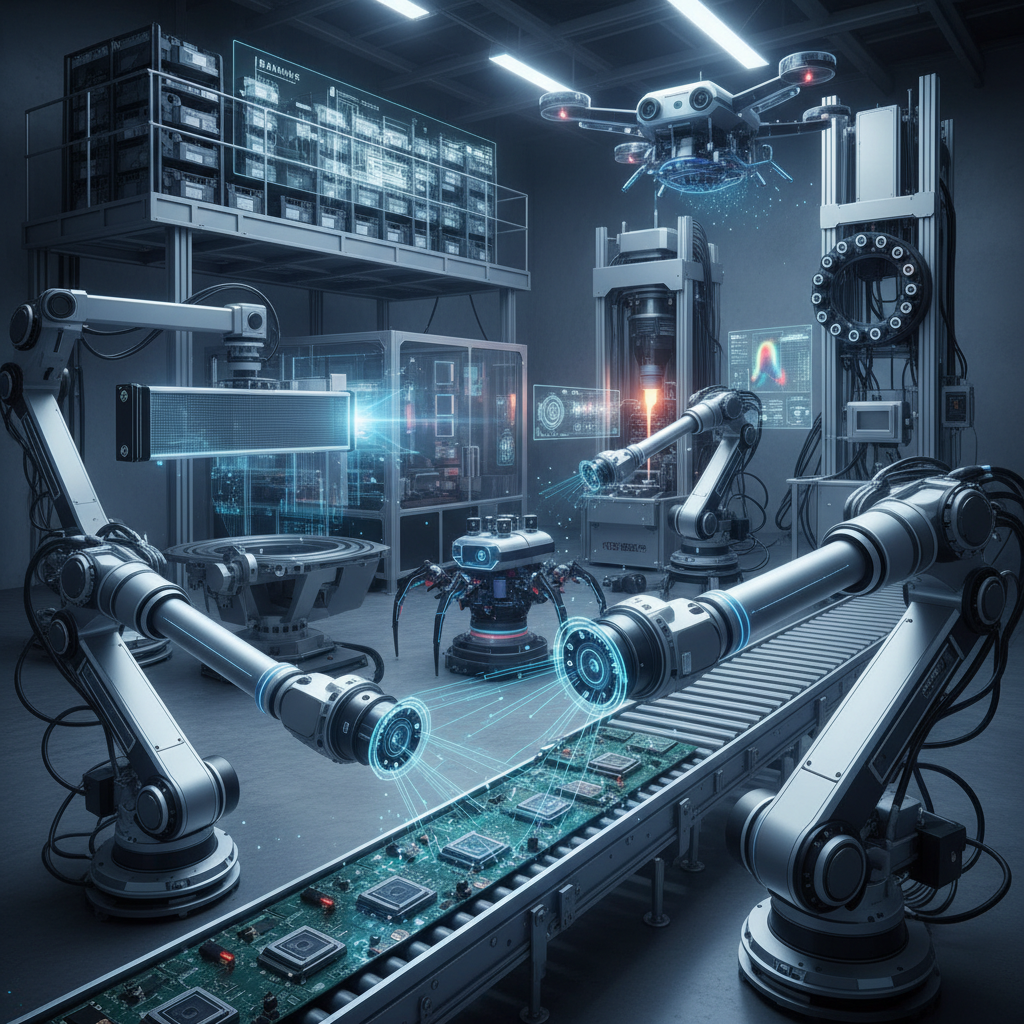

In the rapidly evolving landscape of industrial automation, machine vision systems are at the forefront of transformative technology. These sophisticated systems integrate advanced imaging and processing capabilities to enhance production efficiency, accuracy, and safety across various manufacturing sectors. As industries pivot towards smarter and more automated processes, understanding the dynamics and innovations within machine vision systems becomes increasingly crucial.

This article aims to explore the top five machine vision systems set to revolutionize the industry by 2025. Each of these systems showcases unique features and applications, driving not only productivity but also fostering a culture of continuous improvement in manufacturing environments. By harnessing the power of machine vision, industries can significantly reduce errors, optimize workflows, and ultimately deliver higher quality products to the market.

Through an in-depth analysis, we will uncover how these innovative systems are reshaping the future of automation, setting new standards and benchmarks that will define the next era of manufacturing excellence.

Future Trends in Machine Vision Systems for Enhanced Industrial Automation

The integration of digital twin technology

is rapidly transforming machine vision systems, driving significant growth in industrial automation. By leveraging enhanced simulation design and high-resolution modeling, artificial intelligence facilitates more precise manufacturing processes. This advancement supports innovative applications in areas such as product design and quality control, allowing companies to optimize processes and reduce errors in real-time.

Tips for implementing digital twin technology include starting with a clear understanding of your specific operational goals. Identify key performance indicators that will help you measure the effectiveness of the machine vision systems you implement. Additionally, investing in training for your workforce is crucial to maximize the benefits of these advanced technologies, ensuring that your team can effectively utilize the tools available.

As machine vision systems continue to evolve, industries that adopt these technologies early will likely gain a competitive edge. Companies should explore partnerships with technology providers to stay ahead of the curve and ensure they are utilizing the latest developments in digital twin applications and machine vision integration. This proactive approach will help organizations not only enhance their automation strategies but also position themselves as leaders in the market.

Key Features of Leading Machine Vision Technologies in 2025

In 2025, the landscape of industry automation is being transformed by cutting-edge machine vision systems that boast remarkable features. One of the key advancements is the incorporation of artificial intelligence (AI) algorithms, enabling machines to recognize patterns and make real-time decisions. This capability not only enhances quality control processes but also increases efficiency in the production line, allowing operators to swiftly identify defects and adjust procedures.

Another defining characteristic of leading machine vision technologies is their improved integration with the Internet of Things (IoT). This connectivity facilitates seamless data exchange between devices, providing invaluable insights for predictive maintenance and performance optimization. Manufacturers can monitor systems from a centralized platform, significantly reducing downtime and operational costs.

Tip: When considering a machine vision system, evaluate its adaptability to current and future technologies. A system that offers modular components can be easily upgraded as your needs evolve.

Moreover, advancements in 3D imaging and depth perception are set to revolutionize how industries approach automation. With these technologies, machines can now assess complex objects with precision, enhancing automation in intricate assembly tasks and packaging operations. As industries embrace these innovations, the future of machine vision promises substantial improvements in workflow efficiency and safety standards.

Tip: Always conduct thorough research and pilot testing before fully implementing a new machine vision system to ensure compatibility with existing processes.

Case Studies: Successful Implementations of Machine Vision in Industry

The rapid evolution of machine vision systems has brought about significant advancements in industrial automation. Across various sectors, companies are implementing these technologies to enhance efficiency, reduce error rates, and improve product quality. For instance, a leading automotive manufacturer successfully integrated a machine vision system to monitor the assembly line in real-time. By using high-resolution cameras and advanced image processing algorithms, the system identified defects and inconsistencies, allowing the company to address issues promptly and minimize waste.

In the food processing industry, a major player adopted machine vision for quality control during packaging. The system scans products for size, shape, and labeling accuracy, ensuring compliance with safety standards. This successful implementation not only streamlined operations but also strengthened consumer confidence in product quality.

Tips: When considering machine vision implementation, start with a clear understanding of your specific needs. Assess the areas of your production that require improvements and choose a system that integrates seamlessly with existing workflows. Additionally, ensure your staff receives adequate training to maximize the system's potential and achieve optimal results.

Impact of AI and Deep Learning on Machine Vision Advancements

The integration of AI and digital twin technology is significantly transforming the landscape of machine vision systems in industrial automation. By leveraging advanced simulation designs and high-resolution modeling, manufacturers can achieve unprecedented precision in their production processes. This technological synergy enables innovative applications, such as optimized product design and real-time quality control, which are crucial for maintaining competitive advantages in today’s market. Reports indicate that the machine vision market is projected to grow substantially, with an expected compound annual growth rate (CAGR) of over 7% through 2025, demonstrating a clear trend towards automation facilitated by these advanced technologies.

In recent years, the advancements in deep learning have further enhanced machine vision capabilities. Algorithms have evolved to allow systems to learn and adapt from vast datasets, improving accuracy and efficiency. A significant milestone in this development is the rise of convolutional neural networks, which have revolutionized how machines interpret visual information. Industry data suggests that companies implementing AI-driven machine vision systems can reduce inspection times by 30% while increasing defect detection rates, thus driving down operational costs. This powerful combination of AI and digital twins is poised to not only reshape manufacturing processes but also bolster the broader scope of industrial automation across various sectors.

Evaluating Cost Efficiency and ROI of Modern Machine Vision Systems

Modern machine vision systems are dramatically reshaping industrial automation, prompting business leaders to evaluate their cost efficiency and return on investment (ROI). As organizations increasingly adopt these advanced technologies, understanding the data-driven trends and expected timelines from 2026 to 2030 becomes crucial for strategic decision-making. The ability of machine vision systems to streamline processes, enhance quality control, and reduce operational costs not only boosts productivity but also promises significant long-term savings, making them a core investment for forward-thinking enterprises.

The integration of smart devices in commercial cleaning is another facet of this technological evolution. IoT-enabled systems and robotic scrubbers are reimagining maintenance operations, shifting perceptions from luxury to necessity. These innovations not only improve operational efficiency but also contribute to environmental sustainability, offering business leaders a compelling case for investment. By analyzing the ROI associated with such technology adoptive measures, C-suite executives are better positioned to make informed decisions that align with their corporate strategy and drive sustainable growth in an increasingly automated landscape.

Related Posts

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

-

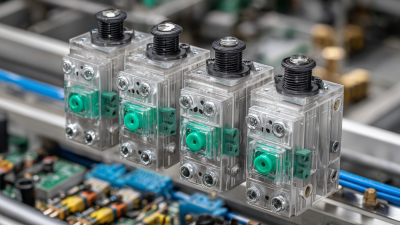

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

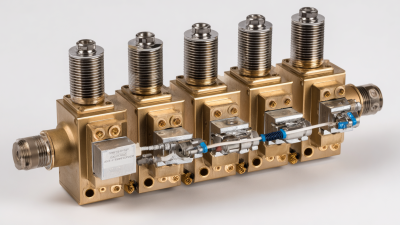

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries