Top 10 Tips for Choosing the Right Air Solenoid for Your Project

When embarking on a project that requires precision and reliability, selecting the right air solenoid can be a pivotal decision that impacts performance and efficiency. Air solenoids serve as essential components in various applications, ranging from automation systems to pneumatic controls. The multitude of options available in the market can be daunting, presenting both opportunities and challenges for engineers and hobbyists alike. Understanding the key factors that differentiate air solenoids will empower you to make an informed choice that aligns with your project's specific requirements.

In this guide, we will explore the top ten tips for choosing the right air solenoid tailored for your unique project needs. Whether you're designing a complex industrial machinery system or simply upgrading a small-scale operation, these insights will help demystify the selection process. By considering aspects such as compatibility, power requirements, and environmental factors, you can ensure that your chosen air solenoid will deliver optimal performance and longevity. Let's delve into these crucial tips to enhance your project outcomes and streamline your decision-making process.

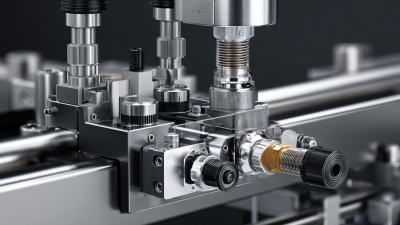

Key Specifications to Consider When Selecting Air Solenoids

When selecting the right air solenoid for your project, it's crucial to focus on several key specifications that can greatly impact performance and efficiency. One major consideration is the solenoid's voltage rating, which typically ranges from 12V to 24V for most applications. According to the International Society of Automation, choosing the correct voltage not only affects the solenoid’s response time but also its longevity. Incorrect voltage can lead to premature failure, which industry sources estimate contributes to nearly 20% of equipment downtime.

Another important specification to consider is the flow rate and pressure. Depending on your project’s requirements, you should ensure the solenoid can handle the necessary air flow (measured in SCFM) and pressure ratings. Reports from the Pneumatic Institute suggest that selecting a solenoid with insufficient capacity can hinder system performance, leading to a potential decrease in operational efficiency by up to 30%.

When making your selection, don't overlook the importance of duty cycle. A device rated for intermittent duty will not perform adequately in continuous operation scenarios. As highlighted by industry experts, the ideal solenoid should match the demands of your application to ensure reliability and reduce maintenance costs in the long run.

Understanding the Role of Duty Cycle in Air Solenoid Selection

When selecting an air solenoid for your project, one critical factor to consider is the duty cycle, which refers to the proportion of time the solenoid is energized versus the time it remains off. Understanding the duty cycle is essential because it directly impacts the solenoid's performance, longevity, and reliability in your application. A higher duty cycle indicates that the solenoid can remain energized for extended periods without overheating, making it suitable for tasks that require continuous operation. Conversely, a lower duty cycle may be sufficient for intermittent applications but can lead to overheating and premature failure if misapplied.

In practical terms, the duty cycle is usually expressed as a percentage. For example, a solenoid rated with a 50% duty cycle can operate for 30 seconds before needing a cooldown period of 30 seconds. Therefore, when selecting an air solenoid, evaluate the expected operational demands of your project to ensure the selected component can handle the required duty cycle without compromising performance. Ignoring this specification may result in inefficiencies and increased maintenance costs, ultimately affecting the overall success of your project.

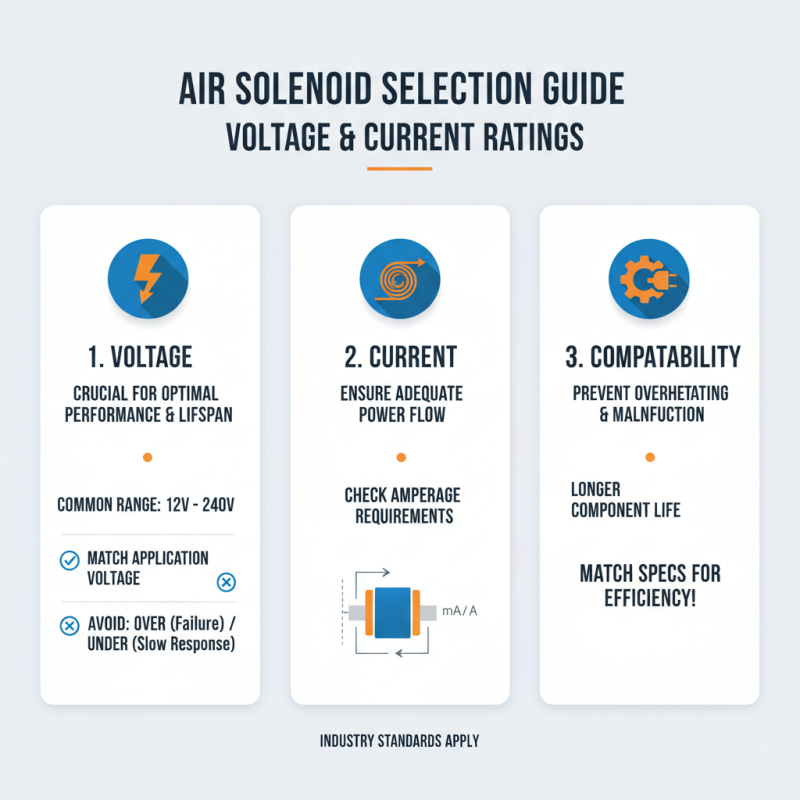

Evaluating Voltage and Current Ratings for Optimal Performance

When selecting the right air solenoid for your project, it’s crucial to evaluate the voltage and current ratings to ensure optimal performance. According to industry standards, solenoids typically operate within a range of voltage levels, commonly from 12V to 240V. Choosing a solenoid that matches the specific voltage of your application not only ensures efficiency but also enhances the lifespan of the component. Over-voltage can lead to overheating and premature failure, whereas under-voltage may result in inadequate performance and slower response times.

Additionally, current rating plays a pivotal role in the selection process. The International Electrotechnical Commission (IEC) emphasizes that solenoids must be operated within their specified current ratings, which generally range from a few hundred milliamps to several amps depending on the design and purpose. For precise applications, such as robotics or industrial automation, it’s vital to consider starting current versus holding current. The starting current can be significantly higher than the holding current, sometimes exceeding the nominal rating by 10-20%. Thus, understanding these electrical specifications is essential to avoid flickering, inconsistent actuation, and potentially damaging the solenoid or the entire system.

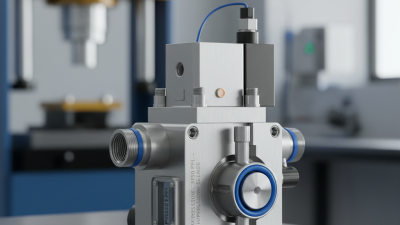

Assessing Environmental Factors Affecting Solenoid Durability

When selecting an air solenoid for your project, one crucial aspect to consider is the environmental factors that can significantly impact the solenoid's durability. Factors such as temperature fluctuations, humidity levels, and exposure to corrosive substances play a pivotal role in the lifespan and performance of the solenoid. For instance, if your project operates in a high-humidity environment, it's essential to choose solenoids with corrosion-resistant materials and seals to prevent moisture ingress.

Another important point is to assess the temperature range the solenoid will encounter. Some solenoids are designed to function optimally only within specific temperature limits. As a tip, always check the manufacturer's specifications and look for solenoids with a wider operational range if your environment is subject to extreme conditions. Additionally, consider mounting orientations and vibration levels; solenoids subjected to continuous movement may require more robust designs to ensure reliability.

Incorporating protection features such as IP ratings can also enhance the durability of your solenoid. Look for those that have high ingress protection levels if your project involves dust or liquid exposure. Understanding these environmental factors will help you make a more informed choice, ensuring your air solenoid performs reliably throughout its intended lifespan.

Environmental Factors Affecting Solenoid Durability

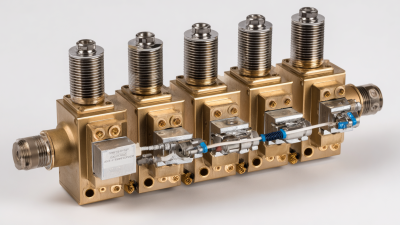

Comparing Cost vs. Quality in Air Solenoid Options for Projects

When selecting the right air solenoid for your project, the debate between cost and quality is paramount. A comprehensive report from the Institute of Electrical and Electronics Engineers (IEEE) indicates that while low-cost solenoids can initially seem attractive, they often lead to increased operational failures and maintenance costs in the long run. Approximately 30% of projects that employed budget solenoid options experienced malfunctions within the first year, ultimately negating initial savings.

On the other hand, investing in higher-quality air solenoids can enhance not only the reliability of your project but also its overall performance. In a study published by the International Society of Automation (ISA), it was revealed that premium solenoid options, albeit 15-25% more expensive, offered a lifespan that exceeded standard models by up to 50%. This data substantiates the idea that investing in quality can yield significant cost-efficiencies, reducing both downtime and the frequency of replacements, thereby saving money over time. Thus, making an informed choice about air solenoids can profoundly impact your project's success and sustainability.

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

| Tip Number | Tip Description | Cost Range (USD) | Quality Rating (1-5) |

|---|---|---|---|

| 1 | Determine the Required Voltage | $10 - $30 | 4 |

| 2 | Check Fluid Compatibility | $15 - $35 | 5 |

| 3 | Assess Power Consumption | $5 - $20 | 3 |

| 4 | Look for a Reliable Manufacturer | $20 - $50 | 5 |

| 5 | Evaluate the Size and Weight | $10 - $25 | 4 |

| 6 | Check the Operating Pressure Range | $15 - $40 | 4 |

| 7 | Research Customer Reviews | $10 - $30 | 5 |

| 8 | Consider Environmental Conditions | $12 - $28 | 4 |

| 9 | Verify Certification Standards | $15 - $45 | 5 |

| 10 | Get Professional Recommendations | $20 - $60 | 5 |

Related Posts

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries