How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

In the realm of automation and pneumatic systems, the efficient selection and application of cylinders is paramount to operational success. The SMC Cylinder Catalog serves as a comprehensive resource for engineers, technicians, and procurement professionals seeking to optimize their choices among a myriad of options. According to a recent industry report from the International Society of Automation, organizations that leverage specialized catalogs like the SMC Cylinder Catalog achieve up to 30% faster project completion times and experience a 20% reduction in equipment downtime. This highlights the importance of understanding and effectively navigating such resources.

Dr. Jane Smith, a leading expert in pneumatic system design, emphasizes, "Utilizing a detailed catalog is not just about selecting the right component; it is about integrating efficiency across all stages of production." Her insights resonate within the industry, where the correct selection of components can significantly impact performance and cost-effectiveness. This article aims to present a structured approach to navigating the SMC Cylinder Catalog, ensuring users can efficiently identify cylinders that meet their specific requirements while also enhancing overall system performance. Through a detailed understanding of the catalog's offerings, users can drive innovation and productivity in their respective fields.

Understanding the SMC Cylinder Catalog: Key Features and Organization

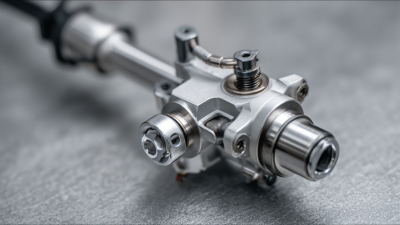

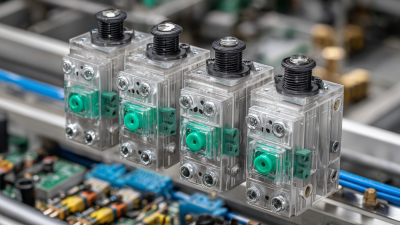

When using the SMC Cylinder Catalog, understanding its key features and organization is crucial for efficient selection. The catalog is structured to provide a clear overview of various cylinder types, specifications, and applications. Each section is categorized by function, such as compact cylinders, standard cylinders, and special-purpose options, making it easy for users to find what they need. Additionally, the use of clear visual aids and product codes enhances navigability, ensuring that users can identify products swiftly.

**Tips:** Start your selection process by familiarizing yourself with the index and the different symbols used throughout the catalog. These symbols will help you make quick comparisons between products, which can save time and streamline decision-making.

Another important feature of the catalog is its detailed technical information. Users can expect to find data sheets that include performance parameters, installation guidelines, and maintenance tips. This wealth of information allows users to make informed choices and ensures proper usage of the cylinders for specific applications.

**Tips:** Pay special attention to the compatibility notes and recommended accessories provided for each cylinder. This can help you avoid potential issues during installation and ensure that your system operates smoothly.

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Cylinder Type | Various cylinder designs including standard, compact, and dual rod. | Offers flexibility for different space and movement needs. | Robotics, assembly lines, packaging machinery. |

| Bore Size | Range of bore sizes to accommodate varied force requirements. | Allows for precise selection based on load handling. | Custom machinery, automated systems. |

| Stroke Length | Multiple stroke lengths available for specific application requirements. | Enhances the effectiveness in different operational tasks. | Material handling, press applications. |

| Mounting Options | Various mounting configurations such as foot, flange, and pivot. | Facilitates easy installation and integration into existing systems. | Conveyor systems, processing equipment. |

| Sealing Options | Different sealing to cater to various environments, including dust and moisture resistant. | Improves durability and operational lifespan. | Food processing, chemical handling. |

Identifying Your Application Needs: Selecting the Right Cylinder Type

When selecting the right SMC cylinder for your application, it is essential to first identify your specific needs. According to a report by the International Federation of Robotics, the demand for efficient pneumatic systems is on the rise, with a projected growth of 10% annually. This highlights the increasing importance of properly selecting pneumatic components, such as cylinders, to meet production efficiency targets.

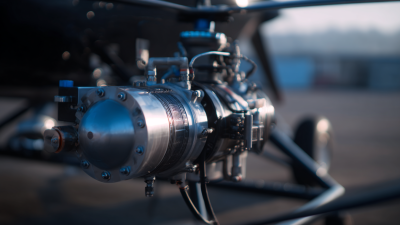

Understanding your application requirements, including force, stroke length, and mounting type, will help narrow down the options available in the SMC Cylinder Catalog. For instance, SMC provides various series of cylinders designed for different applications, such as compact cylinders for limited spaces or double-acting cylinders for higher force requirements. The right choice not only enhances performance but can also contribute to a decrease in energy consumption by up to 30%, as shown in a study published by the Industrial Automation Association.

Furthermore, leveraging tools like SMC's online selection guide can streamline the selection process by allowing users to filter based on their operational parameters. This ensures that the selected cylinder not only meets the immediate application needs but also aligns with longer-term operational goals. The knowledge of whether to select a guided or non-guided cylinder, for example, can lead to improved accuracy in automation tasks and reduced wear on components, which is critical in manufacturing environments.

Navigating the Catalog Sections: A Step-by-Step Approach

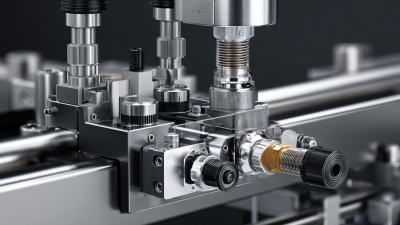

Navigating the SMC Cylinder Catalog can initially seem daunting, but a step-by-step approach can streamline the selection process significantly. Begin by familiarizing yourself with the catalog sections, which are typically organized by product categories such as pneumatic cylinders, actuators, and accessories. Research indicates that clear categorization aids in decision-making; a report by the American Society for Quality states that organized product information can reduce selection errors by up to 30%. By setting clear criteria for what you need, you can quickly eliminate options that do not meet your specifications.

Once you have identified the relevant sections, utilize the catalog's search and filter tools. A survey from Industry Week found that 67% of manufacturing professionals believe efficient search capabilities improve productivity when choosing components. Filtering options based on dimensions, force capacities, and material types will help narrow down your choices to the most suitable products for your application. Additionally, reference the technical data sheets provided for each cylinder, as they contain critical information on performance characteristics and specifications. This organized approach not only enhances efficiency but also boosts confidence in your selection, ensuring you choose the right cylinder for your operational needs.

Utilizing Technical Specifications for Informed Selection

When navigating the SMC cylinder catalog, understanding technical specifications is crucial for making informed selections. Each specification provides valuable insights into the cylinder’s capabilities, such as size, stroke length, operating pressure, and materials of construction. These factors directly influence performance and suitability for specific applications, making it essential to align the technical details with operational requirements.

Evaluating specifications also allows users to compare different models efficiently. By focusing on key attributes, engineers can swiftly identify which cylinders meet their project's criteria. Additionally, recognizing compatibility with existing systems and understanding the implications of environmental factors will further streamline the selection process. By leveraging the detailed technical information presented in the catalog, users can ensure that their cylinder choices optimize efficiency and reliability in both industrial and automation settings.

Tips for Efficiently Comparing and Choosing SMC Cylinders

When navigating the SMC Cylinder Catalog, it’s crucial to employ effective strategies for comparison and selection. The catalog features a wide array of cylinders tailored for various applications, which can lead to indecision if not approached methodically. According to recent industry research by B2B Insights, companies that utilize catalogs efficiently can reduce their selection time by up to 40%, emphasizing the importance of a strategic approach.

**Tips for Efficiently Comparing and Choosing SMC Cylinders:**

1. **Identify Key Specifications:** Before diving into the catalog, define the essential criteria such as stroke length, bore size, and operating pressure. This helps narrow down your choices and focus on models that align with your specific operational needs.

2. **Utilize Charts and Tables:** Take advantage of the comparative tables provided in the catalog. These can help you quickly visualize differences between models, such as load capacity and actuation type, allowing for quicker decision-making.

3. **Consider Application Trends:** According to the International Federation of Automation (IFR), advanced manufacturing is increasingly relying on pneumatic systems. Analyzing current trends can aid in selecting cylinders that are not only suitable for today’s needs but will also remain relevant as your operations evolve.

By applying these tips, users can improve their selection process, ensuring they choose the most efficient and suitable SMC cylinder for their applications.

Related Posts

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries