Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

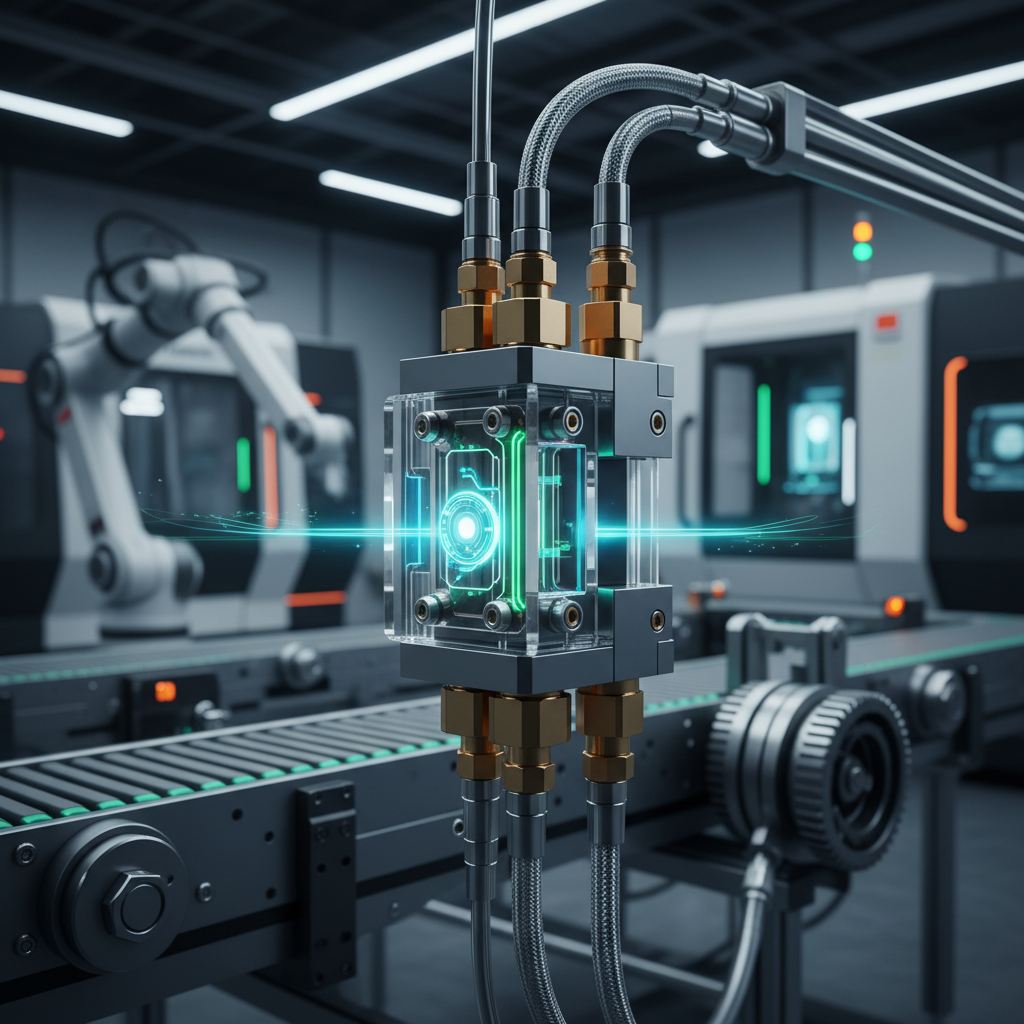

In the rapidly evolving landscape of automation technology, the integration of pneumatic actuator solenoid valves has become essential for enhancing efficiency and productivity in various industrial applications. Leading expert in the field, Dr. Emily Carter, a renowned automation engineer, emphasizes the importance of these devices by stating, “Pneumatic actuator solenoid valves are the backbone of smooth and precise control in automated systems.” This assertion underscores the critical role these components play in streamlining operations and reducing downtime.

As we approach 2025, organizations are increasingly recognizing the value of incorporating advanced pneumatic actuator solenoid valves into their automated systems. These valves not only facilitate quick response times but also offer significant energy savings, which are paramount in achieving operational excellence. With the growing demand for smart automation solutions, understanding the advantages of pneumatic actuator solenoid valves becomes crucial for businesses aiming to stay competitive.

This article will delve into the top five reasons why investing in pneumatic actuator solenoid valves is indispensable for efficient automation. By exploring their functionality, benefits, and future trends, we aim to provide valuable insights that will help industry leaders make informed decisions regarding automation strategies.

Benefits of Using Pneumatic Actuator Solenoid Valves in Automation

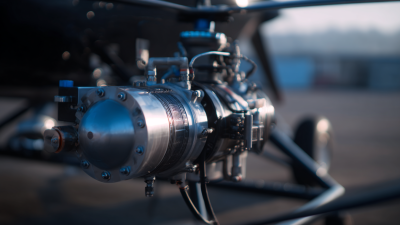

Pneumatic actuator solenoid valves play a crucial role in enhancing the efficiency of automation systems. One of the primary benefits of these valves is their ability to provide swift and precise control over fluid dynamics. When integrated into automation processes, they enable rapid actuation, allowing for quick adjustments in pressure and flow, which is essential in environments where timing is critical. This responsiveness not only optimizes performance but also contributes to energy savings by minimizing excess operational costs.

Another significant advantage of pneumatic actuator solenoid valves is their reliability and durability. Designed to withstand harsh conditions, these valves tend to have a longer lifespan compared to their electric counterparts. This reliability translates into reduced maintenance needs and lower downtime for automation systems. Furthermore, their simplicity in design allows for easy installation and integration into existing setups, making them an attractive option for industries looking to streamline their operations and improve overall productivity.

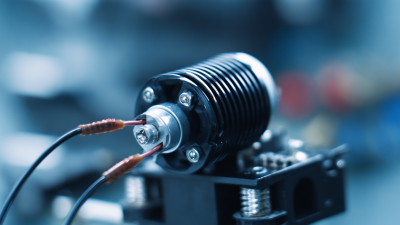

Key Features of Top Pneumatic Actuator Solenoid Valves to Consider

When selecting a pneumatic actuator solenoid valve for efficient automation, several key features are essential to consider.

Firstly, the material of the valve plays a critical role in determining its durability and performance.

Reports indicate that valves made from corrosion-resistant materials such as stainless steel can increase lifespan by up to 50%, reducing operational costs over time.

Additionally, the actuation response time is vital; a quicker response leads to enhanced system efficiency and precision in automation processes, often within the range of 10-20 milliseconds for top-tier models.

Another important factor is the valve's control mechanism.

Features like proportional control provide better flow management, allowing operators to finely tune performance according to specific needs.

In fact, according to a recent industry study, systems utilizing proportional solenoid valves demonstrate up to 30% energy savings compared to traditional ON/OFF valves.

Tips: When evaluating pneumatic actuator solenoid valves, always check for compatibility with your existing systems and ensure adequate flow ratings to meet your operational demands. Additionally, consider the installation requirements, as some models may offer quicker setups and easier maintenance, further enhancing operational efficiency.

Comparative Analysis: Pneumatic Actuator vs. Electric Actuator in Automation

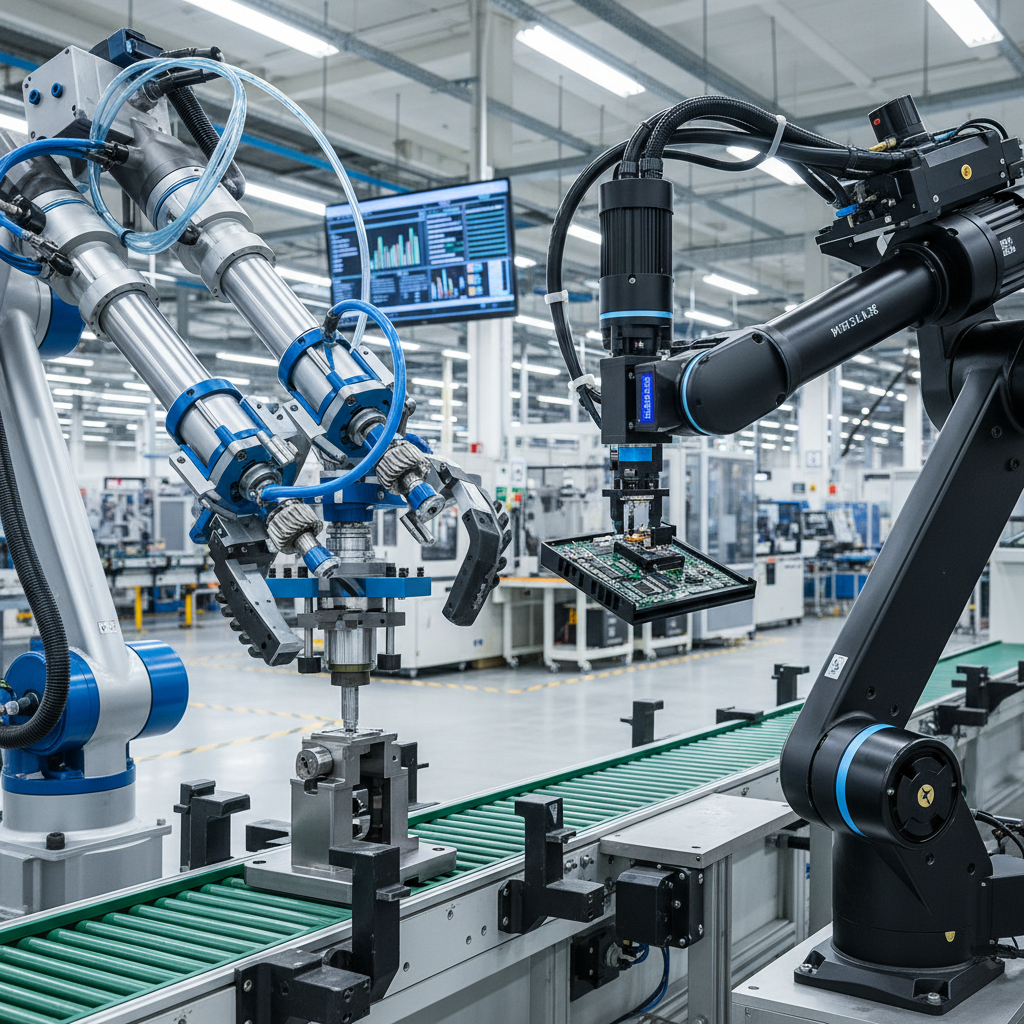

When it comes to automation systems, a critical decision is choosing the right type of actuator. Pneumatic actuators have gained popularity due to their speed and efficiency in various industrial applications. According to a report by Markets and Markets, the global pneumatic actuators market is projected to reach USD 11.71 billion by 2025, growing at a CAGR of 6.5%, indicating strong demand driven by their ability to operate at high speeds and under varying loads. In contrast, electric actuators, while offering precise control and energy efficiency, often cannot match the rapid response times of their pneumatic counterparts.

A comparative analysis shows that pneumatic actuators excel in environments where quick actuation is essential. Their ability to function effectively in extreme temperatures and hazardous conditions further sets them apart, making them ideal for sectors such as manufacturing, food processing, and oil and gas. A study from the International Society of Automation highlights that pneumatic systems can operate with up to 90% efficiency, whereas electric systems typically operate at 70-80%. This efficiency translates to lowered operational costs, particularly in high-demand environments, solidifying the case for pneumatic actuators in automation scenarios where performance and reliability are paramount.

Applications of Pneumatic Actuator Solenoid Valves in Various Industries

Pneumatic actuator solenoid valves play a crucial role in various industries, providing efficient control and automation solutions. The global pneumatic components market is poised for substantial growth, with projections estimating it to increase from $14.81 billion in 2025 to $21.58 billion by 2032. This surge emphasizes the increasing reliance on pneumatic systems across sectors such as manufacturing, oil and gas, and automotive, where precise control in processes is vital.

In conjunction with this trend, the solenoid valve market is also expected to expand significantly. Valued at $4.9 billion in 2025, it is anticipated to reach $7.6 billion by 2035, showcasing a compound annual growth rate (CAGR) of 4.5%. This growth indicates a rising demand for solenoid valves in automation applications, underpinned by the ISA-96 series of standards, which provides a robust framework for the specification and testing of valve actuators and accessories. Industries increasingly incorporate these technologies to enhance efficiency and reliability, reinforcing the need for advanced pneumatic actuator solenoid valves in contemporary automation systems.

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

This chart illustrates the percentage usage of pneumatic actuator solenoid valves across various industries, highlighting their essential role in automation processes.

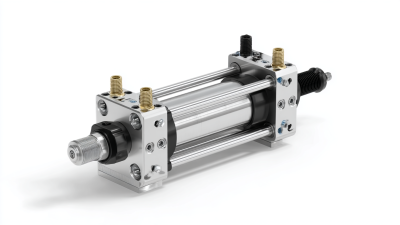

Maintenance Tips for Ensuring Longevity of Pneumatic Actuator Solenoid Valves

Pneumatic actuator solenoid valves are critical components in automation systems, enabling precise control of airflow and fluid dynamics. To ensure their longevity and optimal performance, regular maintenance is essential. According to a report by the International Society of Automation (ISA), valves account for approximately 25% of total plant maintenance costs, highlighting the need for effective upkeep strategies. Regular inspections can identify wear and tear, allowing for timely replacements of any deteriorating components.

One effective maintenance tip is to routinely check for leaks, as even minor leaks can lead to significant efficiency losses. The Pneumatic Institute states that a single leak can waste up to 40% of the system's air supply, thereby increasing operational costs. Additionally, ensuring that the valve is free from contaminants and is properly lubricated can significantly extend its lifespan. Implementing a scheduled maintenance routine not only safeguards the integrity of the pneumatic actuator solenoid valve but also enhances the overall efficiency of the automation process, ultimately leading to reduced downtime and operational costs.

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation - Maintenance Tips for Ensuring Longevity of Pneumatic Actuator Solenoid Valves

| Dimension | Specifications | Maintenance Tip | Longevity Impact |

|---|---|---|---|

| Operating Pressure | 0-10 bar | Regularly check for leaks | Maintains efficiency |

| Temperature Range | -20°C to 80°C | Avoid extreme temperatures | Prevents damage |

| Flow Rate | 3-500 L/min | Monitor for blockage | Ensures optimal operation |

| Voltage | 24V DC | Check electrical connections | Increases reliability |

| Material | Brass/Stainless Steel | Inspect for corrosion | Extends lifespan |

Related Posts

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries