What is a High Pressure Pneumatic Valve and How Does It Work

In the realm of industrial automation, high pressure pneumatic valves play an essential role in controlling the flow of gases and fluids under high pressure. As highlighted by industry expert Dr. Emily Richards, a prominent figure in pneumatic systems engineering, "The efficiency and reliability of a high pressure pneumatic valve can significantly enhance operational processes, ensuring both safety and performance in demanding applications." This statement underscores the critical importance of these valves in various sectors, including manufacturing, aerospace, and automotive industries.

Understanding how a high pressure pneumatic valve operates is fundamental to utilizing its capabilities effectively. These valves are designed to withstand extreme pressures while delivering precise control over the media flow, making them pivotal in systems where pressure management is crucial. By delving into their construction and function, we can appreciate not only the technological advancements in valve design but also their impact on improving system efficiency and safety. As we explore the intricacies of high pressure pneumatic valves, it becomes clear that their significance extends far beyond mere components; they are integral to the optimization of industrial processes.

Definition and Overview of High Pressure Pneumatic Valves

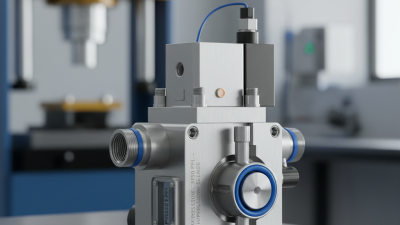

High pressure pneumatic valves are crucial components within various industrial applications, providing efficient control of gas flow under high pressure conditions. These valves are designed to operate effectively in pressure settings that can exceed 1000 psi, making them essential in sectors such as oil and gas, aerospace, and pharmaceuticals. According to a report by MarketsandMarkets, the global pneumatic valve market is anticipated to reach USD 12.5 billion by 2025, reflecting a significant growth driven by advancements in automation and increased demand for efficient systems.

These valves operate by utilizing compressed air to control the motion of the valve disc, enabling precise regulation of airflow. The design typically features a robust body capable of withstanding high operating pressures and temperatures, ensuring reliability and longevity in harsh environments. Furthermore, high pressure pneumatic valves can be actuated either manually or automatically, often integrating with sophisticated control systems that enhance operational efficiency. A report by Technavio highlights that the integration of smart technologies in valve systems is expected to revolutionize the industry, projecting a growth rate of over 6% annually through 2025. This suggests that high pressure pneumatic valves will continue to evolve alongside modern technological advancements, solidifying their role in industrial applications.

Components of High Pressure Pneumatic Valves and Their Functions

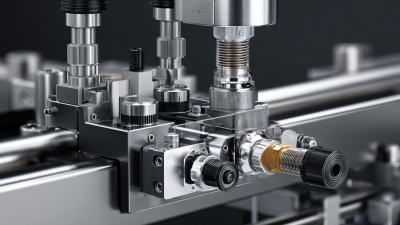

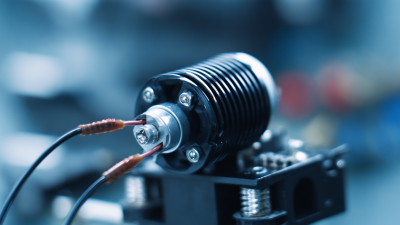

High pressure pneumatic valves are essential components in various industrial applications, particularly in systems requiring precise control of gases under high pressure. These valves are designed to handle operating pressures that often exceed 100 psi, making them critical in sectors such as manufacturing, energy, and transportation. The primary components of a high pressure pneumatic valve include the body, actuator, seat, and sealing elements, each playing a vital role in ensuring optimal performance.

The valve body is constructed from durable materials like stainless steel or brass to withstand high pressure and prevent leakage. The actuator, typically a pneumatic cylinder or a solenoid, controls the opening and closing of the valve. According to a report by MarketsandMarkets, the global pneumatic valve market is projected to grow at a CAGR of 4.8% from 2021 to 2026, driven by the increasing demand for automation across industries. The valve seat is designed to provide a tight seal, preventing any gas from escaping, while the sealing elements are critical for maintaining integrity under extreme conditions. Understanding the intricate functions of these components can help engineers and technicians enhance system reliability and efficiency in high-pressure environments.

Additionally, properly maintained high pressure pneumatic valves can significantly decrease downtime and improve the safety of operations. Industry reports suggest that frequent inspections and timely replacements of worn components can reduce failure rates by up to 30%. By focusing on the functionality of each component and adhering to best practices in maintenance, industries can leverage the benefits of high pressure pneumatic valves for optimal operational performance.

Principles of Operation for High Pressure Pneumatic Valves

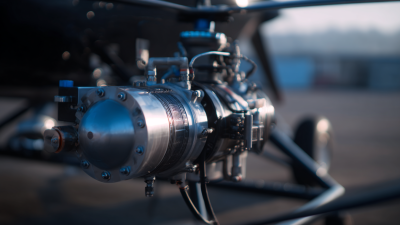

High pressure pneumatic valves are essential components in various industrial applications, controlling the flow of compressed air under significant pressure. The operation principles of these valves are grounded in basic fluid dynamics and mechanical engineering. Typically, they utilize a diaphragm or piston mechanism that responds to pressure differentials. When the valve is activated, the pressure differential between the input and output sides causes the diaphragm or piston to move, either allowing or obstructing the airflow based on the design of the valve. This movement is critical for regulating the flow precisely according to system requirements.

Moreover, the design of high pressure pneumatic valves often incorporates features that enhance their reliability and performance. For instance, many valves include springs that provide a fail-safe mechanism, ensuring that the valve returns to a closed position in case of power loss or failure. Additionally, the materials used in constructing these valves are selected for their durability and resistance to wear, considering the extreme conditions they may encounter. In summary, high pressure pneumatic valves operate through the interplay of mechanical movement and pressure differences, allowing for controlled management of pneumatic systems efficiently.

Performance of High Pressure Pneumatic Valves Under Different Conditions

This bar chart illustrates the flow rates of high pressure pneumatic valves at different pressure levels. As the pressure increases, the flow rate demonstrates a significant upward trend, highlighting the efficiency of these valves in high-pressure applications.

Applications of High Pressure Pneumatic Valves in Industry

High-pressure pneumatic valves play a crucial role in various industrial applications by managing the flow of compressed air or gas. One of the primary uses of these valves is in manufacturing processes, where they regulate air supply to pneumatic cylinders and actuators, ensuring precise control over machinery. By maintaining consistent pressure levels, these valves enhance the efficiency and responsiveness of production lines, making them essential in automated systems.

In addition to manufacturing, high-pressure pneumatic valves are widely utilized in the oil and gas industry. They govern the operation of drilling rigs and production equipment, allowing for safe and reliable management of high-pressure systems. These valves can also be found in the food and beverage sector, where they are essential for controlling pneumatic transport systems, including the movement of bulk materials. Their ability to operate effectively under extreme pressure conditions makes them vital for ensuring operational safety and product integrity across various industries.

In addition to manufacturing, high-pressure pneumatic valves are widely utilized in the oil and gas industry. They govern the operation of drilling rigs and production equipment, allowing for safe and reliable management of high-pressure systems. These valves can also be found in the food and beverage sector, where they are essential for controlling pneumatic transport systems, including the movement of bulk materials. Their ability to operate effectively under extreme pressure conditions makes them vital for ensuring operational safety and product integrity across various industries.

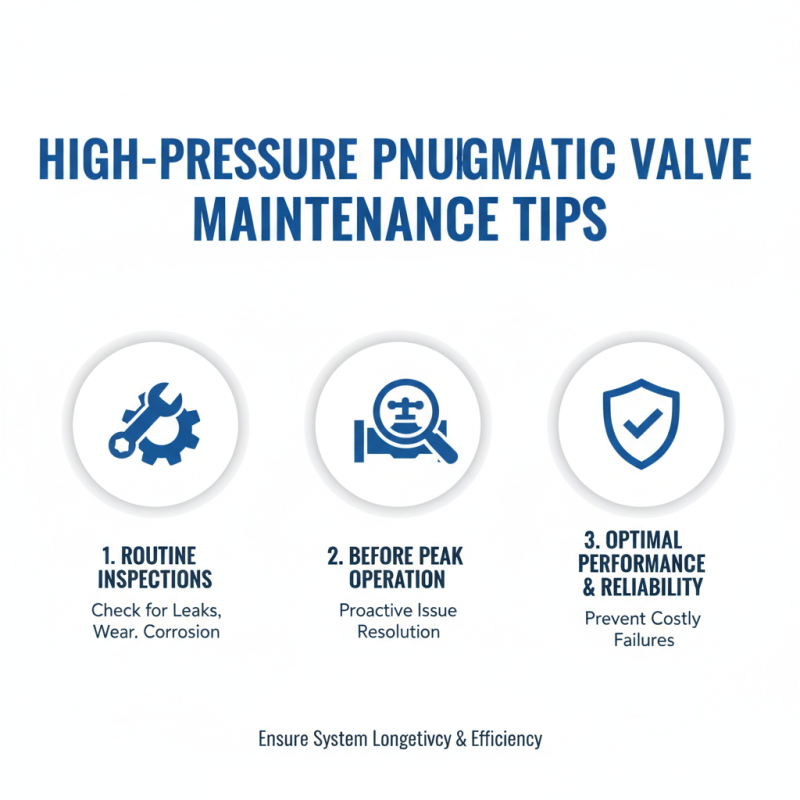

Maintenance and Troubleshooting Tips for High Pressure Pneumatic Valves

High pressure pneumatic valves are critical components in systems that manage high-pressure air or gas. Regular maintenance is essential to ensure optimal performance and prevent costly failures. One important tip is to perform routine inspections, checking for any signs of wear or damage, such as leaks or corrosion. This should be done before peak operating times to address any issues proactively.

Another key aspect of maintaining high pressure pneumatic valves involves ensuring that all connections and fittings are secure. Loose fittings can lead to pressure drops and inefficiencies within the system. Keep an eye on the valve's pressure settings and adjust them only when necessary, as frequent changes can lead to premature wear.

When troubleshooting, it’s crucial to monitor the valve's response to control signals. If the valve is not opening or closing properly, inspect the actuator and the associated control circuitry. Regular cleaning and lubrication of moving parts can also help maintain smooth operation. These practices not only enhance the lifespan of the valves but also improve overall system reliability.

Related Posts

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

Top 10 Tips for Choosing the Best Solenoid Valve Distributors for Your Needs

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries