Exploring the Future of Machine Vision Technologies in 2025 Top Applications

As we approach 2025, the landscape of machine vision technologies is evolving at an unprecedented pace, driven by advancements in artificial intelligence, sensor technology, and imaging software. According to a recent report from ResearchAndMarkets, the global machine vision market is projected to reach $14.68 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.3%. This growth is indicative of the increasing adoption of machine vision systems across various industries, including manufacturing, automotive, and healthcare.

Machine vision encompasses a range of applications that utilize imaging technology to automate tasks traditionally performed by humans, enhancing efficiency and accuracy. The 2023 Machine Vision Market Trends report highlights that sectors such as quality inspection and process automation are among the leading applications fueling this growth, as businesses strive to reduce human error and improve operational productivity. Furthermore, the integration of machine vision with other emerging technologies, such as deep learning and IoT, is set to expand its capabilities, enabling real-time data analysis and smarter decision-making processes.

As we delve into the top applications of machine vision technologies for 2025, it is essential to understand the transformative impact these advancements will have on industries and society. From enhancing safety and precision in manufacturing to revolutionizing diagnostics in healthcare, the future of machine vision presents exciting opportunities for innovation and efficiency across various sectors.

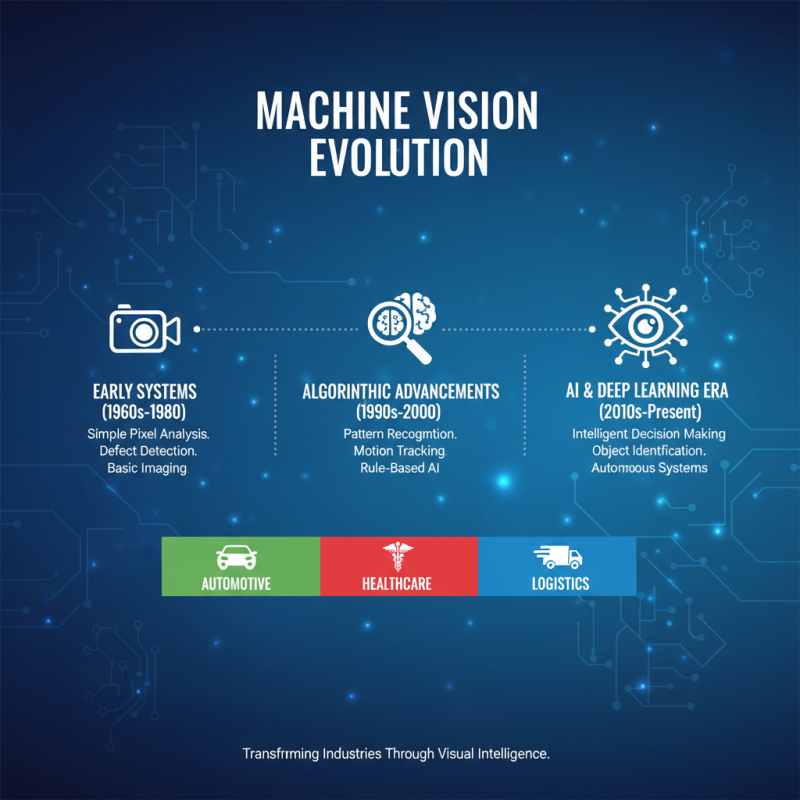

Overview of Machine Vision Technologies and Their Evolution

Machine vision technologies have undergone significant evolution since their inception, transforming industries with their ability to interpret and process visual information. Initially limited to basic imaging functions, early systems utilized simple pixel analysis to detect defects in manufacturing lines. Over the years, advancements in artificial intelligence and machine learning algorithms have enhanced the capabilities of machine vision, enabling systems to recognize patterns, track movements, and even make intelligent decisions based on visual data. This evolution has led to a wide array of applications in sectors such as automotive, healthcare, and logistics.

As we look toward 2025, the future of machine vision technologies appears promising, with innovations expected to further refine their performance and applicability. Enhanced processing power and improved sensors will enable systems to capture high-resolution images in real-time, facilitating more complex analyses. Additionally, the integration of machine vision with other technologies such as robotics and the Internet of Things (IoT) will create synergies that can optimize production processes, improve quality control, and enable smarter supply chain management. With these advancements, machine vision is poised to redefine automation and precision in various sectors, making it an essential component of the modern technological landscape.

Key Trends Influencing Machine Vision Applications by 2025

The landscape of machine vision technologies is set to undergo significant transformation by 2025, driven by several key trends. One of the primary influences is the integration of artificial intelligence and machine learning algorithms, which enhance object recognition and processing capabilities. This evolution allows systems to adapt to varied environments, improving accuracy and efficiency in real-time operations across multiple sectors, such as manufacturing, healthcare, and logistics.

Another notable trend is the advancement of hardware components, including cameras and sensors. As resolution and processing speeds increase, machine vision systems will become more capable of handling complex tasks with greater precision. The adoption of 3D vision systems will also rise, enabling more detailed inspection and analysis of products. These innovations not only enhance operational capabilities but also reduce downtime and operational costs.

Tips: When considering the implementation of machine vision in your business, focus on understanding the specific needs of your operation. Analyze how these technologies can streamline processes and reduce errors. Additionally, investing in training for your team ensures they can leverage these innovations effectively, maximizing the return on investment.

Major Industries Adopting Machine Vision Technologies in 2025

As we approach 2025, machine vision technologies are set to transform numerous sectors by enhancing automation, quality control, and data analysis capabilities. Major industries such as manufacturing, automotive, and healthcare are leading the charge in adopting these advanced systems. According to a report by MarketsandMarkets, the machine vision market is projected to reach $14.90 billion by 2025, reflecting a compound annual growth rate of 7.5% from 2020. This growth can be attributed to the increasing demand for automation in manufacturing processes, where machine vision is vital for defect detection, robotic guidance, and process optimization.

The automotive industry is particularly poised for significant advancements, with machine vision systems being integral for applications such as autonomous driving, safety inspections, and supply chain management. A study by ResearchAndMarkets indicates that the automotive sector accounts for approximately 27% of the overall machine vision market in 2021, and this share is expected to rise as manufacturers integrate these technologies to enhance vehicle safety and reliability. Additionally, the healthcare sector is leveraging machine vision for clinical diagnostics and surgical applications, improving patient outcomes through accurate imaging and analysis. With the potential to streamline operations and reduce human error, the adoption of machine vision technologies across these industries is not just a trend but a pivotal shift towards a more efficient and sophisticated technological landscape.

Future of Machine Vision Technologies in 2025: Top Applications

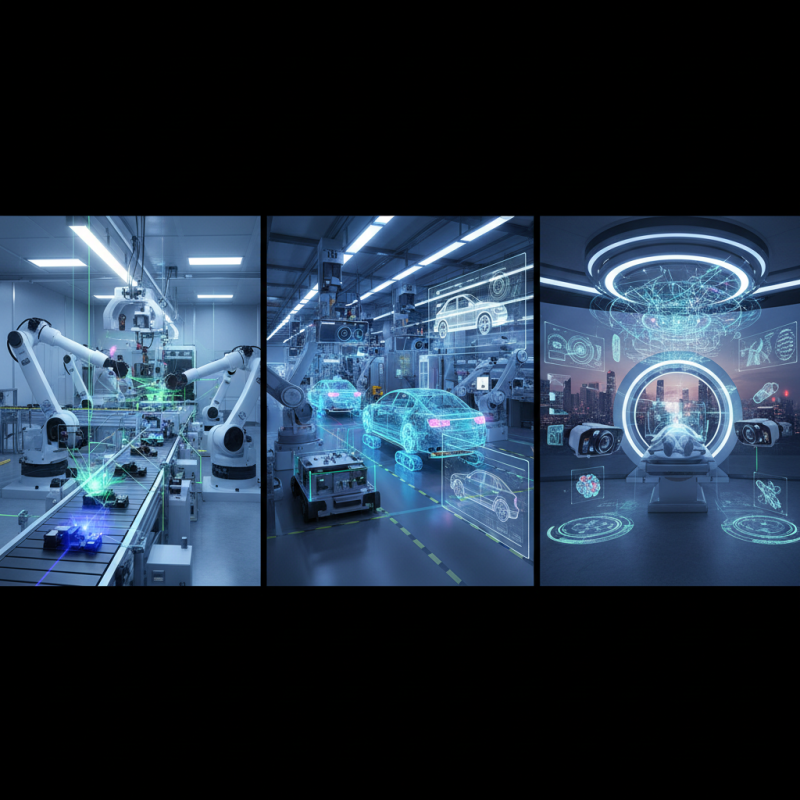

Innovative Applications of Machine Vision in Automation and Robotics

The rapid advancement of machine vision technologies is revolutionizing automation and robotics, particularly in manufacturing and logistics sectors. By 2025, it is estimated that the global machine vision market will exceed $20 billion, driven by the growing need for precision and efficiency in industrial processes. According to a recent report by the International Federation of Robotics, over 1.5 million industrial robots are expected to be deployed worldwide by 2025, with machine vision systems integral to their functionality. These technologies enhance capabilities such as part recognition, quality inspection, and real-time decision-making, eliminating human error and increasing production speed.

Innovative applications of machine vision are not limited to the factory floor; they are finding their way into various fields such as agriculture, healthcare, and transportation. For instance, in agriculture, machine vision systems equipped with advanced algorithms are used for crop monitoring and health assessment, leading to improved yield predictions—an essential aspect as the global population continues to rise. In healthcare, machine vision is enabling more accurate diagnostics through image analysis, contributing to better patient outcomes. Furthermore, in transportation, autonomous vehicles leverage machine vision to navigate and interpret their environments, a critical advancement for the future of smart cities and sustainable urban mobility. As these technologies evolve, they will continue to reshape industries, driving efficiencies and fostering innovation.

Challenges and Opportunities for Future Machine Vision Developments

As the machine vision industry continues to evolve, the landscape in 2025 presents both remarkable opportunities and significant challenges. The global machine vision market is projected to reach $19.36 billion by 2025, growing at a CAGR of 7.2% from 2020, driven by increasing automation and the rising need for quality inspections across various sectors—particularly manufacturing, automotive, and healthcare. This surge in adoption highlights the critical role that machine vision systems will play in facilitating smarter, more efficient production processes.

However, the journey toward widespread implementation is fraught with challenges. One major hurdle lies in the integration of advanced artificial intelligence capabilities into machine vision systems, which requires robust datasets and sophisticated algorithms for effective performance. According to a report from a leading research firm, AI-powered machine vision systems, while potent, face a shortage of high-quality training data, which can hinder their deployment in real-world scenarios. Additionally, addressing issues related to data privacy and security is paramount as organizations increasingly rely on real-time visual data analytics. As organizations navigate these potential pitfalls, they must also explore new partnerships and innovative approaches to enhance the effectiveness and reliability of machine vision technologies, thereby capitalizing on the opportunities that lie ahead.

Exploring the Future of Machine Vision Technologies in 2025: Top Applications, Challenges and Opportunities

| Application | Challenges | Opportunities | Expected Growth Rate (2025) |

|---|---|---|---|

| Automated Quality Inspection | High variability in product designs | Increased accuracy and efficiency in defect detection | 15% CAGR |

| Agricultural Monitoring | Integration with IoT systems | Enhancement of crop yields through precise monitoring | 20% CAGR |

| Autonomous Vehicles | Safety and regulatory issues | Significant advancements in traffic safety | 25% CAGR |

| Facial Recognition | Privacy concerns and ethical issues | Growth in security and retail applications | 18% CAGR |

| Medical Imaging | High costs of technology adoption | Improved diagnostic accuracy and patient outcomes | 22% CAGR |

Related Posts

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

Why You Need a Pneumatic Actuator Solenoid Valve for Efficient Automation

-

How to Choose the Right Air Cylinder for Your Application

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries