10 Essential Tips for Choosing the Right Air Solenoid for Your Needs

Choosing the right air solenoid is a crucial decision that can significantly impact the efficiency and performance of your pneumatic systems. With a myriad of options available in the market, it can be challenging to identify the most suitable solenoid for your specific requirements. Whether you are designing a new system or upgrading an existing one, understanding the key factors that influence your choice will ensure reliable operation and durability of your equipment.

The functionality of an air solenoid directly affects various applications, from automation processes to control systems in manufacturing. As such, selecting the right unit necessitates careful consideration of specifications such as voltage, pressure ratings, and response times. Additionally, the environment in which the air solenoid will operate plays a pivotal role in determining its compatibility and longevity. By following essential tips on this subject, you can navigate the complexities of the selection process and invest in an air solenoid that meets both your operational needs and budgetary constraints.

In this guide, we will provide you with ten critical tips for choosing the right air solenoid that caters to your needs. By equipping yourself with this knowledge, you will be better prepared to make informed decisions that enhance the functionality and reliability of your systems.

Understanding the Basics of Air Solenoids and Their Applications

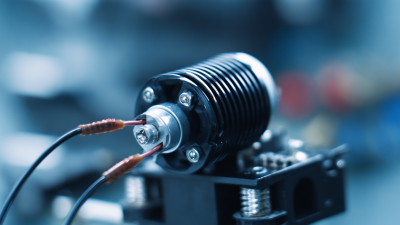

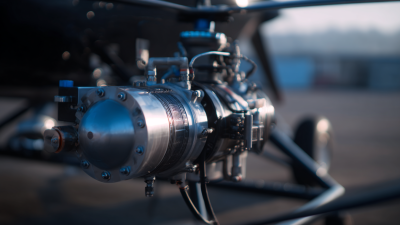

Air solenoids are electromechanical devices that play a crucial role in various applications, converting electrical energy into mechanical motion. They consist of a coil, a plunger, and a casing, allowing them to create an electromagnetic field when electricity is applied. This field pulls the plunger into the coil, thereby controlling the flow of air in pneumatic systems. Understanding these basic components and their functions is essential for effectively integrating air solenoids into any application.

The versatility of air solenoids makes them vital in numerous industries, including automation, automotive, and manufacturing. They are commonly used for controlling valves, engaging brakes, or activating pneumatic actuators. Understanding the specific requirements of your operation, such as the needed response time, pressure ratings, and duty cycle, is essential for selecting the right air solenoid. Equally important is considering the environmental conditions in which the solenoid will operate, including factors like temperature, humidity, and exposure to contaminants, as these can affect performance and durability. By grasping the fundamentals of air solenoids and their diverse applications, users can make informed decisions that enhance efficiency and reliability in their systems.

Factors to Consider When Selecting an Air Solenoid

When selecting an air solenoid, several critical factors come into play that can significantly influence your decision. First and foremost, understanding the operational requirements of your application is essential. Consider the pressure ratings needed for your specific use, as different solenoids are designed to operate under varying pressure levels. Additionally, the voltage and current specifications must align with your existing systems to ensure compatibility and optimal performance.

Another important aspect to evaluate is the environment in which the air solenoid will be installed. Factors such as temperature extremes, humidity levels, and potential exposure to corrosive substances can affect the solenoid's durability and efficacy. Selecting a solenoid built to withstand these conditions can prevent premature failure and costly downtime. Moreover, consider the size and mounting configurations available, as these will determine how easily the solenoid can be integrated into your existing setup while maintaining functionality and accessibility for maintenance.

Evaluating the Performance Specifications of Air Solenoids

When evaluating the performance specifications of air solenoids, it's crucial to consider factors such as voltage, current, and the force exerted by the solenoid. The working voltage is typically specified in either AC or DC, and selecting the appropriate voltage ensures compatibility with your system. Current draw impacts the power consumption and may dictate the choice of power supply. Furthermore, understanding the force output is vital, as it determines the solenoid's ability to handle the required load and perform effectively in your application.

Another important specification to evaluate is the response time of the solenoid. This characteristic defines how quickly the solenoid can activate and deactivate, which is essential for applications requiring precise timing. Additionally, consider the duty cycle of the solenoid, indicating how long it can operate before needing a cooling period. High duty cycles are necessary for applications that demand continuous operation. Lastly, the environmental conditions, such as temperature and humidity, should also be taken into account to ensure that the solenoid can withstand the operational environment without compromising performance.

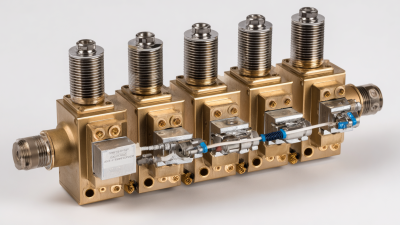

Exploring Different Types of Air Solenoids and Their Features

When selecting the right air solenoid for your specific application, it's crucial to understand the various types and their distinct features. Air solenoids generally come in two main types: direct-acting and pilot-operated. Direct-acting solenoids are ideal for low-pressure applications and offer swift actuation. Their simplicity makes them a prevalent choice in smaller systems. On the other hand, pilot-operated solenoids are suited for higher pressure and larger systems, using a small pilot signal to control the flow of air. According to industry reports, pilot-operated solenoids can handle pressures up to 150 PSI, making them invaluable in heavy-duty applications.

When choosing an air solenoid, it's essential to consider specific features that cater to your operational needs. For instance, look for solenoids that offer durability against environmental conditions, such as moisture and temperature fluctuations. Some models come equipped with seals that enhance their resistance to dust and debris, ensuring longevity and reliability.

Tip: Always verify the voltage ratings and response times required for your system. Many solenoids are available in both AC and DC configurations, and selecting the correct voltage can greatly impact performance and efficiency. Additionally, consider the flow rates that your solenoid can handle; this is often a critical factor in ensuring that your system operates smoothly and effectively, particularly in automated processes. Exploring these options will help you make an informed decision that aligns with your application needs.

Air Solenoid Types and Their Features

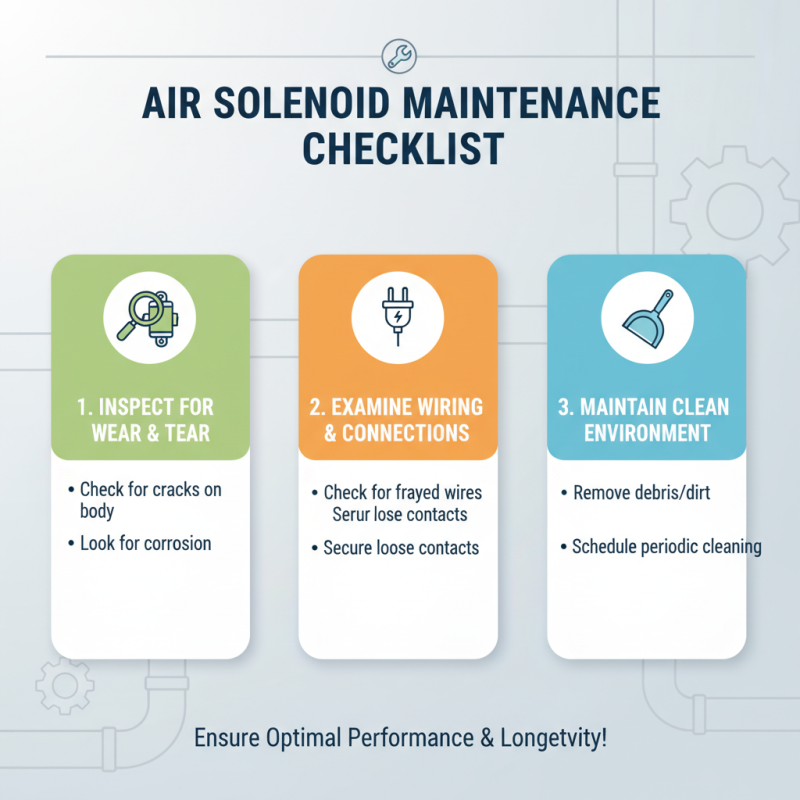

Maintenance and Troubleshooting Tips for Air Solenoids

When it comes to maintaining air solenoids, regular inspection is key to ensuring optimal performance. Begin by checking for signs of wear and tear, such as cracks or corrosion on the solenoid body. It's also essential to inspect the wiring and connections for fraying or loose contacts, as these can lead to poor operation or total failure. Maintaining a clean environment around the solenoid helps prevent debris and contaminants from interfering with its functionality, so consider periodic cleaning as part of your maintenance routine.

In the event of troubleshooting an air solenoid, start with a thorough check of the power supply. Ensure that the solenoid is receiving the correct voltage and current. If the solenoid fails to actuate, you may need to test the coil resistance to diagnose potential issues. Additionally, listen for unusual noises such as buzzing or clicking; these can indicate mechanical blockage or internal faults. Keeping detailed records of maintenance and any issues that arise not only aids in troubleshooting but also ensures that you are prepared for any future challenges. With consistent attention to these areas, your air solenoids can maintain their reliability and efficiency.

Related Posts

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

-

Top 10 Solenoid Valve Distributors: Find the Best Suppliers Near You

-

Top 10 Tips for Choosing the Best Solenoid Valve Distributors for Your Needs

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries