How to Choose the Right Pneumatic Air Cylinder for Your Application

In today's rapidly advancing industrial landscape, the selection of the right pneumatic air cylinder is crucial for optimizing performance and efficiency in various applications. According to a report by MarketsandMarkets, the global pneumatic cylinder market is expected to grow from USD 2.9 billion in 2020 to USD 4.1 billion by 2025, reflecting an annual growth rate of approximately 7.1%. This surge in demand underscores the necessity for manufacturers and engineers to understand the specific requirements of their projects when choosing pneumatic air cylinders.

The appropriate selection process involves considering critical factors such as stroke length, bore size, mounting type, and the operating environment. Research conducted by the International Fluid Power Society indicates that improperly specified pneumatic components can lead to inefficiencies, increased operational costs, and potential system failures. Hence, investing time and resources into selecting the right pneumatic air cylinder can not only enhance productivity but also extend equipment longevity, ultimately resulting in significant cost savings.

As industries continue to evolve and embrace automation, the insights into pneumatic air cylinders become even more pivotal. This ensures that professionals are well-equipped to make informed decisions tailored to their unique applications, thereby improving system reliability and performance across various sectors. In this article, we will delve into the essential criteria for selecting the most suitable pneumatic air cylinder for your specific needs.

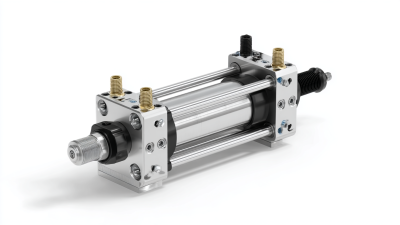

Understanding the Different Types of Pneumatic Air Cylinders Available

When selecting a pneumatic air cylinder for your application, it's essential to

understand the various types available. The most common categories include single-acting cylinders,

double-acting cylinders, and rotary actuators.

Single-acting cylinders utilize air pressure to extend a piston, while a spring retracts it. In contrast, double-acting

cylinders employ air pressure for both extension and retraction, providing a more powerful and controlled motion.

Rotary actuators convert linear motion into rotational movement, making them invaluable in applications that require

precise turning.

According to industry reports, the global pneumatic cylinder market was valued at approximately $4 billion

in 2022 and is expected to grow at a CAGR of over 5% through 2030. This growth is fueled

by increasing automation in manufacturing processes and the demand for efficient, space-saving solutions.

Understanding the specifications, such as bore size, stroke length, and operating pressure,

is critical for optimizing performance and ensuring compatibility with your system.

Tips: When choosing an air cylinder, evaluate the load requirements

and cycle frequency of your application to select a model that offers the best performance.

Additionally, always consider the environmental conditions, such as temperature and humidity, which can affect

the cylinder's lifespan. Lastly, opting for a cylinder with adjustable stroke limits can enhance versatility in various applications.

Key Specifications to Consider When Selecting Pneumatic Air Cylinders

When selecting pneumatic air cylinders for your application, understanding key specifications is crucial. First, consider the bore size, which directly impacts the force output of the cylinder. A larger bore size generates more force, making it suitable for heavy-duty applications, while smaller bore sizes are ideal for light tasks. According to industry reports, choosing the correct bore size can improve system efficiency by up to 30%, thereby optimizing performance.

Another vital specification is the stroke length. This determines the distance the piston travels within the cylinder and is essential for applications requiring precise movements. Data suggests that applications with varying stroke requirements can benefit greatly from adjustable stroke pneumatic cylinders, providing flexibility and reducing the need for multiple different models.

**Tip:** Always assess the application environment. Factors like temperature, humidity, and potential exposure to chemicals can greatly influence the suitable materials for your pneumatic cylinder. Opting for corrosion-resistant materials in harsh environments can enhance the longevity of your equipment.

**Tip:** Evaluate the actuation speed. Faster speeds can increase productivity but may also lead to decreased control. Striking a balance between speed and accuracy is key, as inappropriate settings might cause wear and tear, reducing the cylinder's lifespan.

Key Specifications of Pneumatic Air Cylinders

This chart illustrates the key specifications to consider when selecting pneumatic air cylinders, including Bore Diameter, Stroke Length, Pressure Rating, Cycle Life, and Operating Temperature. Each specification is essential for ensuring the optimal performance suited for specific applications.

Assessing the Force and Stroke Requirements for Your Application

When selecting a pneumatic air cylinder for your application, understanding the force and stroke requirements is paramount. The force generated by a cylinder is determined by its diameter and the pressure applied. To calculate the force, one can use the formula: Force = Area x Pressure. Therefore, assessing the operational pressure of the system alongside the required output force will help narrow down suitable cylinder sizes. Ensuring that the cylinder can deliver adequate force to perform the intended task—be it lifting, pushing, or clamping—is essential for optimal performance and efficiency.

Stroke length is another critical aspect to consider. The stroke is the distance the piston travels within the cylinder, and it must be sufficient to complete the required motion in your application. To determine the correct stroke length, evaluate the specific requirements of your machinery or process. Consider any potential obstacles and the full range of motion needed for the application. Additionally, taking into account the possibility of future adjustments or expansions in your system is wise, as this can influence the choice of cylinder stroke length. Making informed decisions regarding both force and stroke will enhance the effectiveness of the pneumatic system and ensure reliability in operations.

Evaluating the Operating Environment and Its Impact on Cylinder Choice

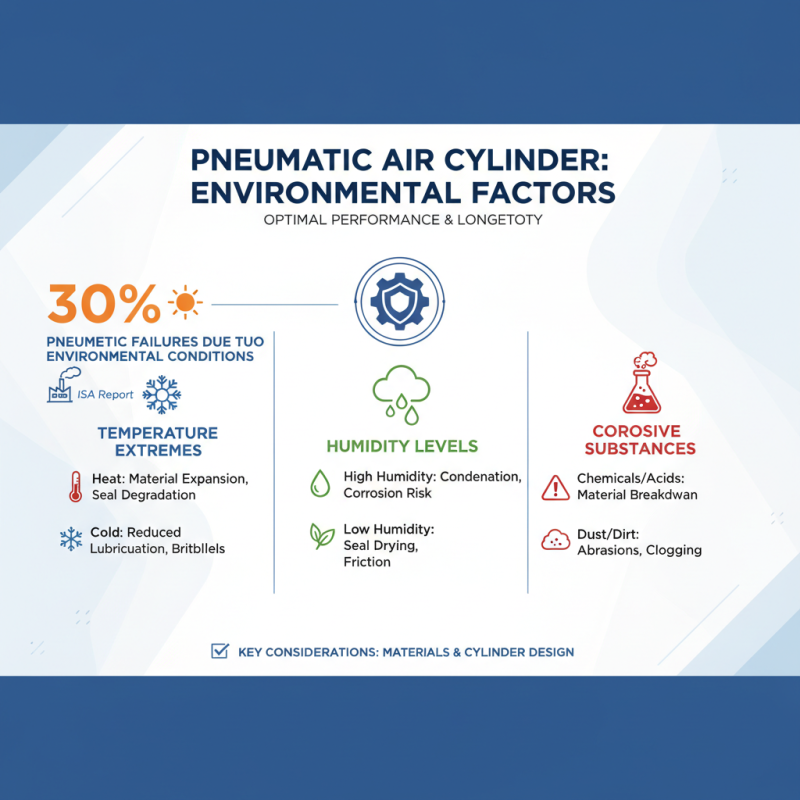

When choosing the right pneumatic air cylinder for a specific application, it's crucial to evaluate the operating environment, as environmental factors can significantly impact the performance and longevity of the cylinder. According to a report from the International Society of Automation, approximately 30% of pneumatic failures are attributed to environmental conditions, stressing the importance of this consideration. Factors such as temperature extremes, humidity levels, and exposure to corrosive substances can affect the choice of materials and design of the cylinder.

In harsh environments, such as those found in food processing or chemical manufacturing, selecting a cylinder with corrosion-resistant coatings and seals is essential. For example, studies indicate that pneumatic components exposed to moisture without proper protection can lose efficiency by up to 25%. Additionally, temperature fluctuations can alter the material properties of seals, leading to potential failure. The report emphasizes that environments with high dust levels require cylinders with additional filtration systems to prevent particulate contamination. Understanding these environmental impacts can guide engineers in selecting a cylinder with the appropriate specifications to ensure reliability and efficiency in their operations.

Comparative Analysis of Cost, Efficiency, and Maintenance for Pneumatic Cylinders

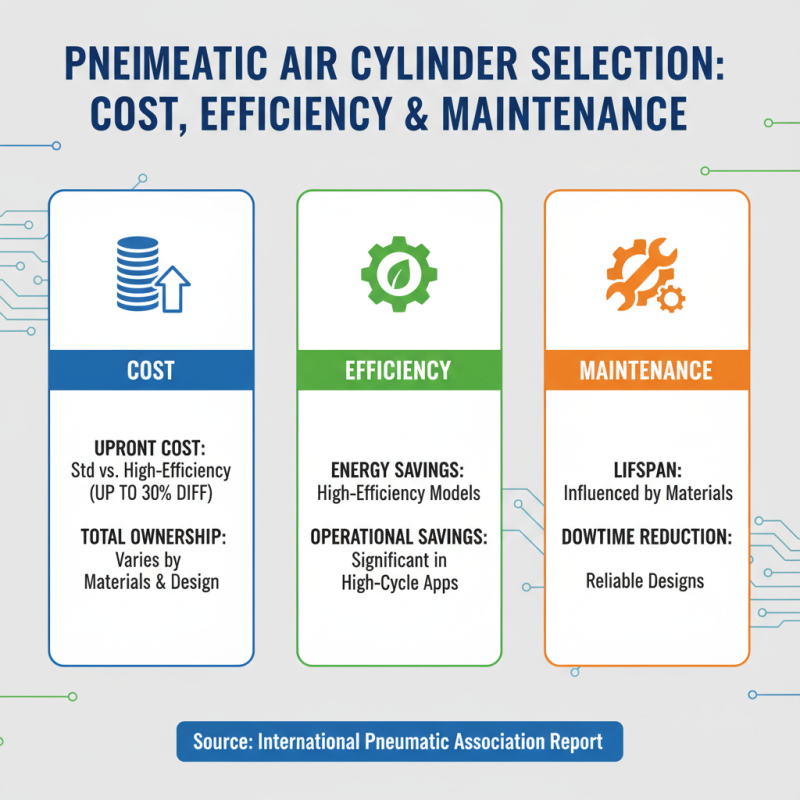

When selecting the right pneumatic air cylinder for your application, the evaluation of cost, efficiency, and maintenance is crucial. According to an industry report by the International Pneumatic Association, the total cost of ownership for pneumatic cylinders can significantly vary based on the selected materials and designs, with a difference of up to 30% between standard and high-efficiency cylinders. High-efficiency models, while potentially more expensive upfront, can lead to considerable savings in energy consumption and operational costs over time, particularly in high-cycle applications.

In terms of maintenance, studies indicate that traditional pneumatic cylinders require routine upkeep, often resulting in downtime that can exceed 15% of operational hours. Conversely, advanced pneumatic cylinders are designed with lower wear and longer lifespans, contributing to reduced maintenance frequency. For example, a report from the Association of Industrial Automation reveals that upgrading to a maintenance-free cylinder can reduce maintenance time by up to 50%, providing substantial improvements in productivity. This highlights the importance of not only initial cost considerations but also the long-term implications of efficiency and maintenance on operational performance and budgeting.

Related Posts

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

-

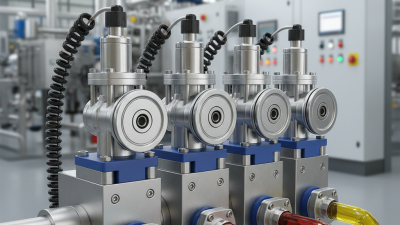

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

How to Choose the Right Air Cylinder for Your Application

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

Top 10 Solenoid Valve Distributors: Find the Best Suppliers Near You

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries