How to Choose the Right Norgren Valves for Your Industrial Applications 2025

Choosing the right Norgren valves for your industrial applications is crucial for optimizing efficiency and ensuring operational reliability. In 2025, as industries evolve and demands for precision and performance increase, the selection process becomes even more critical. With a myriad of options available, understanding the specific requirements of your application is essential to make an informed choice.

Norgren valves stand out due to their robust design, advanced technology, and versatility across various industrial sectors. This guide aims to provide insights into the key factors to consider when selecting Norgren valves, including flow rates, pressure capacities, and compatibility with different media. By focusing on these elements, you can ensure that your system operates smoothly and meets the rigorous standards expected in today’s industrial landscape. As we explore the top five considerations for 2025, we'll delve into how these valves can enhance performance while mitigating potential challenges in your operations.

Identifying Key Industrial Applications for Norgren Valves

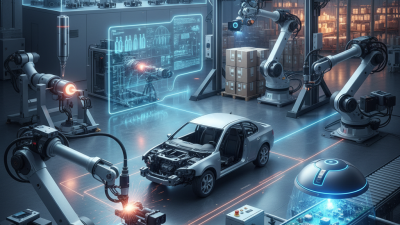

Norgren valves are crucial components in various industrial applications, particularly in sectors that require precision engineering and reliable performance. Identifying the right applications for these valves can substantially enhance operational efficiency and safety. For instance, in the automotive industry, a report by Allied Market Research revealed that the global automotive valves market was valued at approximately $73.7 billion in 2021 and is projected to reach $107.4 billion by 2030. This growth underscores the demand for high-performance valves that can withstand the pressures and complexities involved in manufacturing processes.

Additionally, the food and beverage industry, with its stringent hygiene standards, benefits significantly from the use of Norgren valves. According to a recent survey by Fortune Business Insights, the global food and beverage processing pumps market—which encompasses valve technology—was valued at $30.2 billion in 2021, and is expected to grow at a compound annual growth rate (CAGR) of 5.4% over the next decade. This highlights the necessity for valves that not only ensure precision and control but also comply with safety standards, making Norgren a preferred choice for manufacturers aiming to maintain quality and efficiency in their production lines.

Evaluating the Performance and Efficiency of Norgren Valve Types

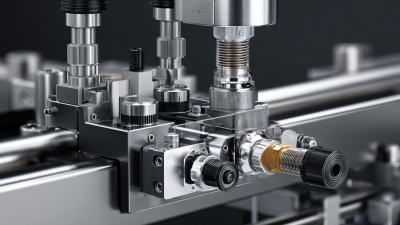

When selecting the appropriate Norgren valves for industrial applications, evaluating the performance and efficiency of various types is paramount. Each valve type offers distinct features that cater to specific operational needs, such as pressure, flow rates, and media compatibility. For instance, solenoid valves are often chosen for their rapid operation and precise control, making them ideal for automated systems. On the other hand, pneumatic valves provide robust solutions for heavy-duty applications, consistent performance under varying pressures, and durability, which are essential for maintaining operational efficiency in demanding environments.

Moreover, assessing the efficiency of Norgren valves involves understanding their energy consumption and maintenance requirements. High-efficiency models are designed to minimize energy loss while maximizing performance, which can significantly reduce operational costs over time. Additionally, implementing valves with easy maintenance features can lead to less downtime and smoother operations. By carefully considering these performance metrics and efficiency aspects, businesses can ensure that they select the right Norgren valves that not only meet their immediate operational needs but also contribute to long-term sustainability and cost-effectiveness in their industrial processes.

Performance Comparison of Different Valve Types

This bar chart illustrates the performance and efficiency metrics of various valve types commonly used in industrial applications. The data reflects key performance indicators such as flow rate (L/min) and pressure drop (bar) across different valve types, helping users make informed decisions when selecting the right valve.

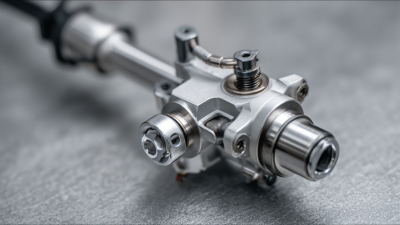

Understanding Material Compatibility for Norgren Valves in Industry

When selecting Norgren valves for industrial applications, understanding material compatibility is critical. The right materials can prevent corrosion, ensure reliable performance, and extend the valve's lifespan. For instance, according to a recent report by the International Society of Automation, improper material selection accounts for approximately 30% of valve failures in critical systems. In industries such as oil and gas, where harsh chemical environments prevail, using materials like stainless steel, PTFE, and brass can significantly enhance durability and performance.

Tips: Always consult the material compatibility charts provided by manufacturers like Norgren. These charts detail how various materials react under different environmental conditions, helping you make informed decisions. Additionally, consider factors such as temperature, pressure, and the specific fluids the valves will come into contact with, as these aspects significantly influence material selection.

Furthermore, conducting regular maintenance and inspections is essential. According to industry estimates, proactive maintenance can reduce unexpected failures by nearly 40%. This not only saves costs associated with downtime but also improves overall operational efficiency. By prioritizing material compatibility and maintenance, industries can ensure that their Norgren valves perform optimally and reliably.

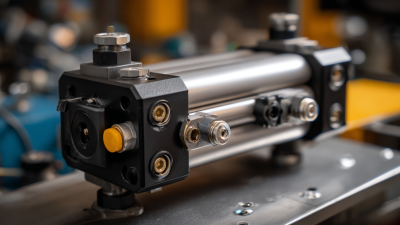

Assessing Maintenance Needs and Lifespan of Norgren Valves

When selecting Norgren valves for industrial applications, assessing their maintenance needs and lifespan is crucial for ensuring operational efficiency and minimizing downtime. Regular maintenance is essential to prolong the life of valves, as it helps identify potential issues before they escalate. Consider establishing a routine inspection schedule that includes checking for leaks, wear, and other performance indicators.

Tips: To streamline maintenance, keep detailed records of each valve's service history. This will aid in identifying recurring issues and facilitate timely interventions. Also, invest in quality training for your maintenance team to ensure they are familiar with Norgren valve specifics and best practices.

The lifespan of Norgren valves can be influenced by several factors, including the environment in which they operate, the type of media they control, and the frequency of use. Understanding these factors can help you select the right valve for your application. Additionally, manufacturers often provide guidelines regarding the expected lifespan under different conditions, enabling better planning for replacements and minimizing unexpected failures.

Tips: Consider implementing a predictive maintenance program that uses data analytics to monitor valve performance in real-time. This proactive approach can help in adjusting maintenance schedules based on actual wear and tear, greatly extending the overall lifespan of your valves.

Comparing Costs and Budget Considerations for Norgren Valve Selection

When selecting Norgren valves for industrial applications, it is crucial to consider the costs and budget implications to ensure a worthwhile investment. Begin by evaluating the specific requirements of your application, such as flow rates, pressure, and medium compatibility. Understanding these factors will help narrow down your choices, allowing for a more cost-effective selection that meets performance standards without overspending.

Tips: Always include total cost of ownership in your budget considerations. This encompasses not just the purchase price but also maintenance, installation, and potential energy costs over the valve's lifespan. Additionally, look for opportunities to bundle purchases or consider long-term contracts with suppliers like Norgren, which can lead to significant savings.

Moreover, consider the scalability of the valves you select. Choosing components that align with future expansion plans can save costs in the long run. Investing in adaptable valves facilitates upgrades without the need for full replacements, ensuring that your budget remains intact even as operational demands change.

Related Posts

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

2025 Top 5 Machine Vision Systems Revolutionizing Industry Automation

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries