How to Choose the Right Air Cylinder for Your Application

In the world of mechanical systems, selecting the appropriate air cylinder can significantly impact the efficiency and functionality of your application. Industry expert Dr. Sarah Thompson, a leading mechanical engineer known for her work on pneumatic systems, emphasizes the importance of this decision by stating,

“Choosing the right air cylinder is crucial, as it directly influences the performance and reliability of a machine.”

With a multitude of options available, understanding the key factors that differentiate one air cylinder from another is essential for engineers and designers alike.

When faced with various specifications, such as stroke length, mounting style, and pressure ratings, it can be daunting to make the best choice. The right air cylinder not only enhances productivity but also ensures safety and longevity of the equipment involved.

This introduction will delve deeper into the considerations and best practices to follow when selecting an air cylinder, empowering you to make informed decisions that align with your operational needs.

By taking the insights from experts in the field and applying them to your unique situation, you can optimize your application’s performance in an increasingly competitive landscape.

Understanding Air Cylinder Basics and Functions

When selecting the right air cylinder for a specific application, it is crucial to grasp the fundamentals of air cylinder design and functionality. Air cylinders are devices that convert compressed air energy into mechanical motion, commonly utilized in industrial automation. According to a report by MarketsandMarkets, the global pneumatic cylinder market is projected to reach USD 4.4 billion by 2026, driven by increasing adoption in sectors such as manufacturing and robotics. Understanding the basic types—double-acting, single-acting, and rodless cylinders—can help users match the right product to their needs based on stroke length, force requirements, and operating environment.

Furthermore, compatibility with the application is paramount. For instance, operating temperature and exposure to contaminants can significantly impact cylinder performance and longevity. A study from the International Journal of Pneumatics indicates that choosing the wrong materials or configurations can reduce efficiency by up to 30%. By aligning the air cylinder’s specifications, such as bore size and mounting style, with the specific application demands, users can enhance system performance and minimize downtime. Proper venting, cushioning, and seal materials are also essential considerations that can affect the operation and maintenance of air cylinders in various environments.

Identifying Application Needs and Specifications

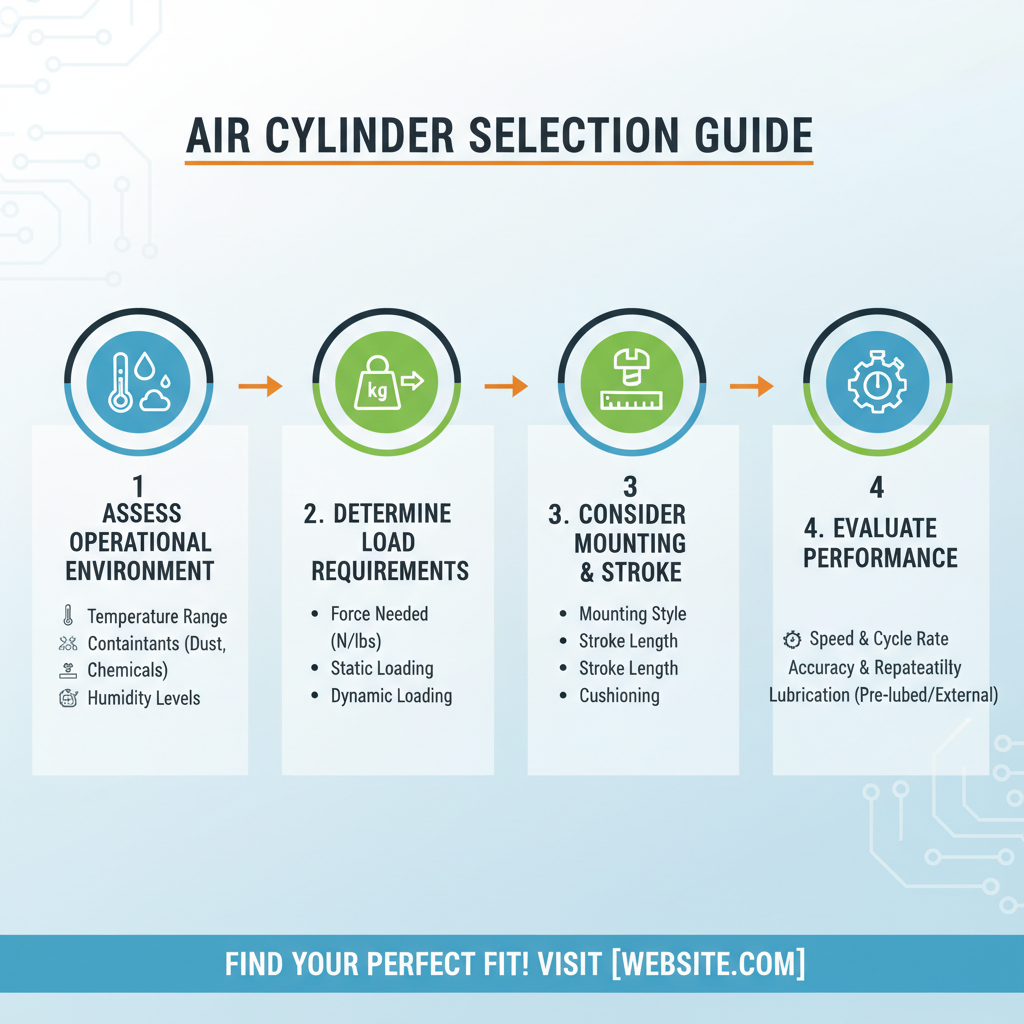

When selecting the right air cylinder for your application, it is crucial to first identify your specific needs and requirements. Begin by assessing the operational environment in which the cylinder will be used. Factors such as temperature range, presence of contaminants, and humidity levels can significantly impact the performance and longevity of the air cylinder. Additionally, understanding the load requirements is essential. Determine the force needed to accomplish the task, and consider both static and dynamic loading conditions to ensure the selected cylinder can handle the application effectively.

Next, pay close attention to the specifications that will maximize efficiency and reliability. Stroke length, mounting style, and bore size are key specifications that should align with the application's demands. For example, a longer stroke length may be necessary for applications requiring extensive movement, while bore size will influence the force output of the cylinder.

Furthermore, consider the type of actuation required, whether single-acting or double-acting, and ensure compatibility with your control system. By meticulously evaluating these parameters, you can make an informed decision that enhances operational performance and reduces maintenance costs.

Evaluating Cylinder Types and Their Characteristics

When selecting the right air cylinder for your application, it's crucial to evaluate cylinder types and their characteristics based on specific operational requirements. Pneumatic cylinders primarily fall into two categories: double-acting and single-acting cylinders. According to the International Federation of Robotics, double-acting cylinders account for approximately 70% of pneumatic applications, due to their ability to exert force in both directions, making them ideal for tasks that require consistent performance, such as automated assembly and packaging processes.

Furthermore, the design and materials used in air cylinders significantly affect their functionality and lifespan. For instance, the use of anodized aluminum in cylinder casing increases resistance to corrosion and wear, enhancing durability in demanding environments. A report from the National Fluid Power Association indicates that incorporating advanced seals can reduce leakage by up to 50%, which is critical for maintaining efficiency in high-pressure systems. Understanding these characteristics and their implications can help businesses optimize performance and reduce maintenance costs in their pneumatic systems.

Air Cylinder Types and Their Characteristics

This chart compares various types of air cylinders based on their force output in Newtons (N). Understanding the force capability of different cylinder types helps in selecting the appropriate one for specific applications.

Selecting Materials and Construction for Durability

When selecting the right air cylinder for your application, it is crucial to focus on the materials and construction that ensure durability. Recent advancements in eco-friendly construction materials, such as high-strength products made from industrial and agricultural waste, highlight the importance of sustainability in product design. These materials not only reduce carbon emissions but also provide long-lasting performance, making them ideal for applications that demand reliability under challenging conditions.

In the context of air cylinders, choosing materials that align with these evolving sustainability standards adds another layer of durability. For instance, incorporating waste-based materials can enhance the environmental profile of air cylinders while maintaining their strength and longevity. Additionally, utilizing data-driven design principles can help engineers select components that contribute to the overall resilience of the system. By prioritizing eco-friendly options and innovative construction techniques, manufacturers can create air cylinders that not only meet immediate performance needs but also support broader sustainability goals within the construction industry.

Ensuring Proper Sizing and Actuation for Performance

When selecting the right air cylinder for your application, ensuring proper sizing and actuation is essential for optimal performance. Industry data indicates that nearly 30% of air cylinder failures can be traced back to improper sizing. This underscores the importance of accurately assessing the load requirements, stroke length, and speed necessary for your application. Using a cylinder that is too small can lead to inadequate force, while an oversized cylinder can waste energy and reduce overall efficiency. The Pneumatic Manufacturers Association (PMA) highlights that proper sizing enhances not only the lifespan of the cylinder but also the performance of the entire pneumatic system.

In addition to sizing, actuation method also plays a critical role in system efficiency and performance. Pneumatic systems can utilize different actuation methods such as double-acting, single-acting, or powered options. According to a report by the International Fluid Power Society, systems that leverage double-acting cylinders often experience up to 25% higher operational efficiency compared to single-acting counterparts, as they allow for greater control over the motion and force output. Therefore, assessing both the sizing and the actuation type will significantly affect the reliability and effectiveness of the air cylinder in your application, ultimately leading to enhanced productivity and reduced operational costs.

How to Choose the Right Air Cylinder for Your Application - Ensuring Proper Sizing and Actuation for Performance

| Application Type | Cylinder Type | Bore Size (mm) | Stroke Length (mm) | Max Pressure (bar) | Actuation Type |

|---|---|---|---|---|---|

| Assembly Line | Double Acting | 50 | 100 | 6 | Pneumatic |

| Material Handling | Single Acting | 32 | 75 | 8 | Pneumatic |

| Robotic Applications | Compact Cylinder | 25 | 50 | 10 | Electric |

| Automated Packaging | Tie Rod Cylinder | 63 | 150 | 6 | Pneumatic |

Related Posts

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries