Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

In the competitive landscape of industrial automation, the efficiency and reliability of pneumatic systems are paramount. A critical component to achieving optimal system performance is the selection of high pressure pneumatic valves. According to a report by the National Fluid Power Association, leveraging high pressure pneumatic valves can lead to a significant reduction in energy consumption, improving system efficiency by up to 30%. This highlights the importance of making informed choices when it comes to pneumatic components.

Industry expert Dr. Emily Chen, a leading authority in pneumatic systems, states, "The correct application of high pressure pneumatic valves not only enhances performance but also contributes to longer equipment lifespans and reduced operational costs." This assertion underscores the necessity of these valves in enhancing the overall efficiency of pneumatic systems, particularly in high-stakes environments where precision and reliability are non-negotiable.

As we delve deeper into the factors that make high pressure pneumatic valves indispensable, it becomes clear that their design, functionality, and application are critical to maintaining the integrity of industrial processes. By understanding the vital role these components play, businesses can better position themselves to optimize their systems and improve productivity.

Understanding High Pressure Pneumatic Valves and Their Role in System Efficiency

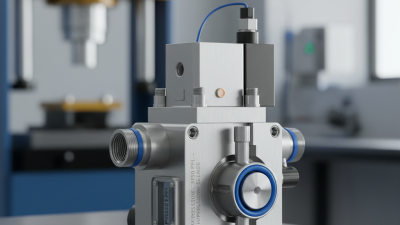

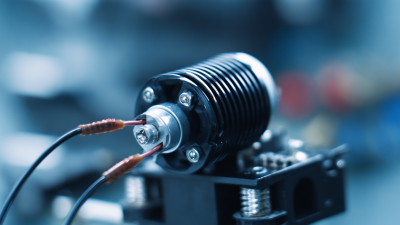

High pressure pneumatic valves play a crucial role in optimizing system efficiency across various industrial applications. These valves are designed to control the flow and pressure of compressed air within a system, ensuring that operations run smoothly and effectively. By managing the air supply with precision, high pressure pneumatic valves minimize energy losses that can arise from leaks or improper flow regulation. This level of control is essential in applications where maintaining pressure is vital for performance and safety, such as in manufacturing and processing plants.

Moreover, the selection of high pressure pneumatic valves significantly impacts the overall performance of pneumatic systems. The right valves can enhance responsiveness and reliability, reducing downtime and maintenance costs. They enable quicker actuation of machinery, which contributes to increased productivity. Additionally, these valves often come with advanced features such as quick exhaust functions and adjustable flow rates, allowing for more tailored system configurations. Understanding the significance of these components can lead to better decision-making when designing and implementing high-pressure pneumatic systems, ultimately achieving enhanced operational efficiency.

Key Benefits of High Pressure Pneumatic Valves for Industrial Applications

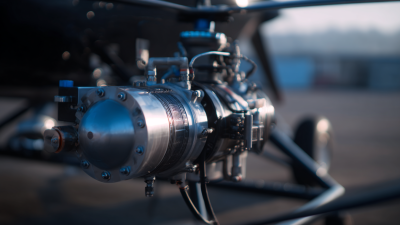

High pressure pneumatic valves play a crucial role in various industrial applications, significantly enhancing system performance. One of the primary benefits of these valves is their ability to operate efficiently under high-pressure conditions, allowing for increased flow rates and improved responsiveness. This robustness is essential in environments such as manufacturing and oil and gas, where rapid pressure changes can occur, demanding reliable and quick-acting components. The optimized design of high pressure pneumatic valves ensures minimal energy loss and maximizes the operational efficiency of pneumatic systems.

Moreover, high pressure pneumatic valves contribute to safety and longevity in industrial settings. By maintaining precise control over pressure levels, these valves prevent potential failures or accidents that could arise from pressure fluctuations. This control leads to reduced maintenance costs and less downtime, ultimately enhancing productivity. Additionally, the ability of these valves to handle aggressive media without degrading further supports their application in challenging environments, thereby ensuring consistent performance and durability over time.

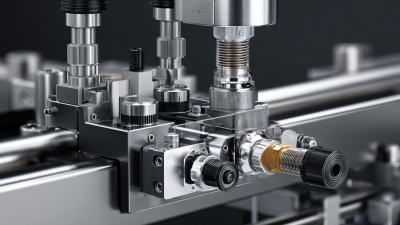

Factors to Consider When Selecting High Pressure Pneumatic Valves

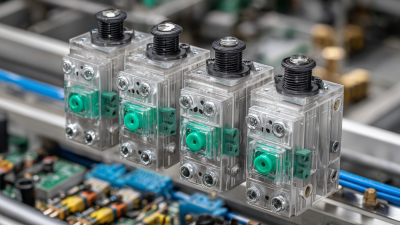

When selecting high pressure pneumatic valves, several critical factors must be considered to ensure optimal system performance. First, the valve material is paramount, as it must withstand extreme pressures and temperatures typical in high-pressure applications. According to a report by the International Valve Group, choosing the right materials — such as stainless steel or specialized alloys — can enhance valve longevity and reduce maintenance costs by up to 30%.

Another crucial factor is the valve actuation method. Pneumatic valves can be actuated manually, electrically, or pneumatically, each offering different advantages depending on the operational requirements. A study published by the Pneumatics Research Association indicates that systems employing automated pneumatic actuation improve efficiency by as much as 20% compared to manual systems, as they reduce response times and enhance precision in flow control.

Lastly, the flow characteristics and pressure rating of the valve should align with the specific application requirements. The American Society of Mechanical Engineers (ASME) suggests that selecting valves rated for pressures significantly above the system's maximum can ensure safety and reliability, minimizing the risk of failure under demanding conditions. Ensuring these factors are considered during the selection process is essential for achieving efficient system performance.

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

| Factor | Importance | Consideration | Recommended Range |

|---|---|---|---|

| Pressure Rating | Ensures safety and functionality | Select a valve matching the system's max pressure | Up to 10,000 psi |

| Material Compatibility | Prevents corrosion and wear | Evaluate the media being transmitted | Stainless steel, brass, or plastic |

| Flow Rate | Affects system efficiency | Consider required flow rates for operations | 0.1 to 400 SCFM |

| Actuation Type | Impacts response and control | Choose between manual, pneumatic, or electric | Varies by application |

| Installation Space | Critical for ease of access and maintenance | Measure available space before selecting a valve | Compact vs. standard sizes |

Maintenance Practices to Ensure Optimal Performance of Pneumatic Valves

Regular maintenance practices are vital to ensure the optimal performance of pneumatic valves, which are essential components in high-pressure systems. According to a report by the Pneumatic Valves Market Analysis 2022, regular maintenance can extend the lifespan of these valves by up to 30%, significantly reducing replacement costs and downtime. Key practices include routine inspections, cleaning of valve components, and timely lubrication. Ensuring that pneumatic valves operate under the recommended pressure specifications can prevent wear and tear, ultimately enhancing system efficiency.

Moreover, industry standards suggest that implementing a predictive maintenance strategy can further improve operational excellence. A study by the International Journal of Advanced Manufacturing Technology found that predictive maintenance can decrease unscheduled downtime by nearly 50%. By using advanced monitoring technologies, such as pressure sensors and automated diagnostics, operators can identify potential issues before they escalate. Thus, regular maintenance, combined with modern predictive techniques, not only ensures the reliability of pneumatic valves but also optimizes the performance of the entire system, leading to higher productivity and reduced operational costs.

Future Trends in High Pressure Pneumatic Valve Technology and Design

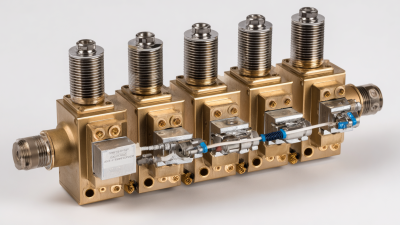

The future landscape of high pressure pneumatic valve technology is characterized by innovative designs and enhanced materials that promise increased efficiency and durability. Research from the Pneumatics Industry Association indicates that advancements in materials, such as carbon fiber composites, can reduce the weight of valves by up to 30%, leading to improved performance in high-pressure systems. These modern materials not only enhance operational efficiency but also contribute to energy savings, aligning with the industry’s shift towards sustainability.

Moreover, the integration of smart technologies into valve design is set to revolutionize system performance. According to a report by Market Research Future, the smart valve market is projected to grow at a compound annual growth rate of 12% from 2023 to 2030. High pressure pneumatic valves equipped with IoT capabilities allow for real-time monitoring and predictive maintenance, drastically reducing downtime and increasing reliability. As industries continue to seek higher levels of automation and efficiency, these trends in high pressure pneumatic valve technology will play a crucial role in optimizing system operations and meeting the demands of a rapidly evolving market.

Related Posts

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries