Why Choose a Machine Vision System for Your Industrial Applications?

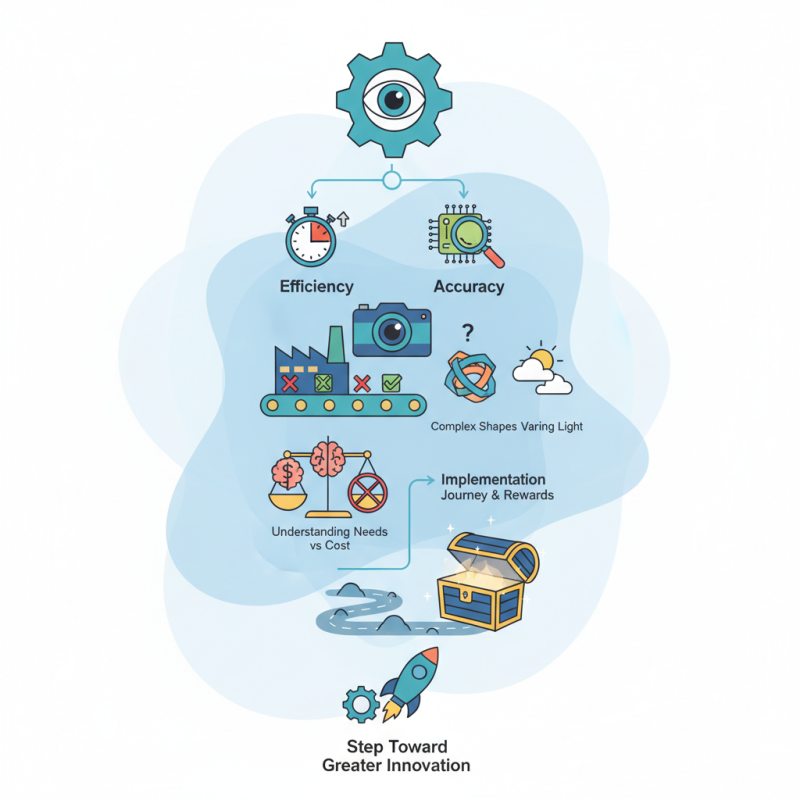

In the realm of industrial applications, the adoption of advanced technology is paramount. A machine vision system stands out as a transformative solution. According to Dr. Emily Chen, a leading expert in visual inspection technology, "A machine vision system can improve efficiency and accuracy like never before." Industries are increasingly recognizing this potential.

Factories are integrating machine vision systems to enhance quality control. These systems provide real-time analysis for products on production lines. They detect defects that human eyes might miss. However, challenges exist. Some machines may struggle with complex shapes or varying light conditions.

Choosing the right machine vision system is not simply a matter of cost. It requires understanding specific needs and limitations. Not every system suits all applications. The journey to implementation can be bumpy, but the rewards are substantial. Embracing this technology is a step toward greater innovation.

Understanding Machine Vision Systems in Industrial Settings

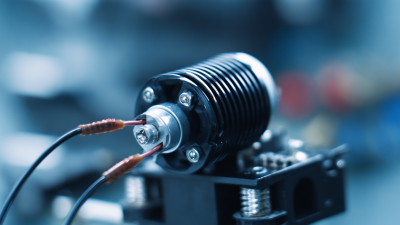

Machine vision systems are becoming integral in industrial environments. These systems use cameras and software to capture and analyze images. They can detect defects, measure parts, and guide robots, all with remarkable precision. This technology streamlines processes and increases efficiency. However, their implementation can be complex.

Understanding these systems involves recognizing their components. Cameras capture high-resolution images, while lighting is crucial for reducing shadows and glare. Image processing software interprets the data. Not all setups work flawlessly; some require adjustments to lighting or calibration. Each factory's environment is unique, presenting challenges.

Adopting machine vision is not merely a plug-and-play solution. It demands careful planning and integration. Training staff to interpret results is vital. Misinterpretations can lead to costly mistakes. While machine vision systems offer immense benefits, they also necessitate a commitment to continuous improvement and problem-solving. Embracing this technology involves anticipating hurdles and being willing to adapt.

Why Choose a Machine Vision System for Your Industrial Applications?

| Application Area | Benefits | Key Features | Common Use Cases |

|---|---|---|---|

| Quality Control | Increased accuracy, reduced defects | High-resolution imaging, real-time analysis | Inspecting components for flaws |

| Assembly Verification | Ensures correct assembly of parts | Pattern recognition, verification algorithms | Checking assembly in manufacturing lines |

| Barcode and Label Reading | Improved efficiency, reduced human error | Optical character recognition (OCR) | Reading barcodes on packaging |

| Robot Guidance | Enhanced precision, improved automation | 3D vision, object tracking | Guiding robots for pick and place tasks |

| Surface Inspection | Detects surface defects, enhances product quality | Lighting control, high-speed imaging | Checking for scratches or blemishes on products |

Key Benefits of Implementing Machine Vision in Manufacturing

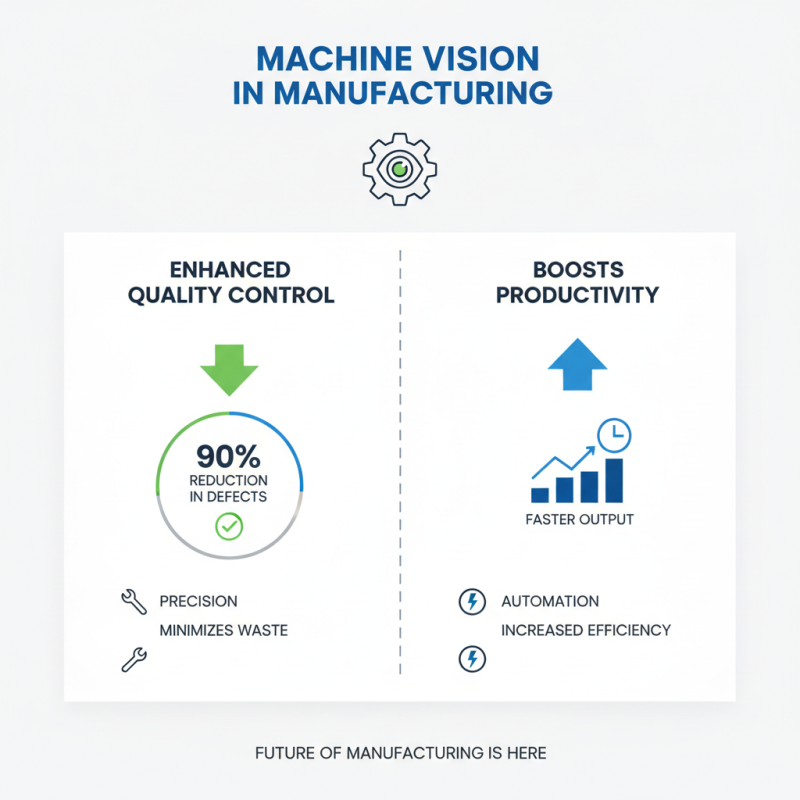

Machine vision systems are rapidly gaining traction in manufacturing. One key benefit is enhanced quality control. Studies show that companies using machine vision can reduce defects by up to 90%. This precision minimizes waste and boosts productivity.

Implementing machine vision also speeds up inspection processes. Automated quality checks replace manual labor. For instance, a machine vision inspection can process thousands of items per hour. Manual inspections may only handle a fraction of that volume. Such efficiency is crucial in high-demand environments.

Tips: Regularly update your machine vision algorithms. This ensures they adapt to new products and changing quality standards. Training staff on system capabilities maximizes effectiveness.

Consider the initial costs of these systems. Some companies report challenges in achieving a quick return on investment. It’s important to plan for long-term gains. Investing in the right technology can lead to significant savings over time.

Comparing Machine Vision Systems to Traditional Inspection Methods

Machine vision systems are revolutionizing industrial applications. Unlike traditional inspection methods, they offer speed and precision. Traditional methods often rely on human inspectors. These inspectors can be slow and prone to errors. Human fatigue can also affect the quality of inspections. Machine vision systems, on the other hand, work tirelessly. They can analyze thousands of parts in a fraction of the time.

Accuracy is another key point. While human inspectors might miss small defects, machine vision excels in detail. It detects variations not visible to the naked eye. However, there are challenges. Setting up a machine vision system can be complex. Lighting conditions, camera angles, and software calibration require expertise. A poorly configured system can lead to inaccurate results.

Cost is also a factor to consider. Initial investment in machine vision technology can be high. Yet, the long-term savings often justify the expense. Increased efficiency leads to reduced waste and greater output. Companies must weigh their options carefully. Traditional methods might be easier to implement but can be less efficient over time. In the end, the choice may come down to specific needs and available resources.

Application Areas of Machine Vision in Various Industries

Machine vision systems have revolutionized various industries. From manufacturing to agriculture, these systems play a critical role. In manufacturing, they enhance quality assurance. They can detect defects in products with an accuracy rate exceeding 90%. This ensures that only high-quality items reach the consumers.

In the food processing sector, machine vision is essential. It helps identify the ripeness of fruits and vegetables. A report indicated that vision systems can reduce waste by up to 30%. This is crucial for maintaining efficiency and sustainability. However, not all applications yield perfect results. Some challenges include varying lighting conditions and diverse product shapes.

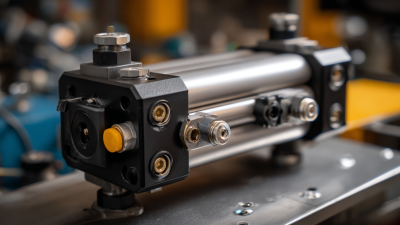

The automotive industry also benefits from machine vision. Systems can streamline parts inspection processes. Studies show that using these systems can cut inspection time in half. Yet, integrating machine vision systems can require significant investments. Companies must evaluate the return on investment carefully. These systems sometimes struggle with complex environments, leading to potential decision-making delays.

Future Trends in Machine Vision Technology for Industrial Use

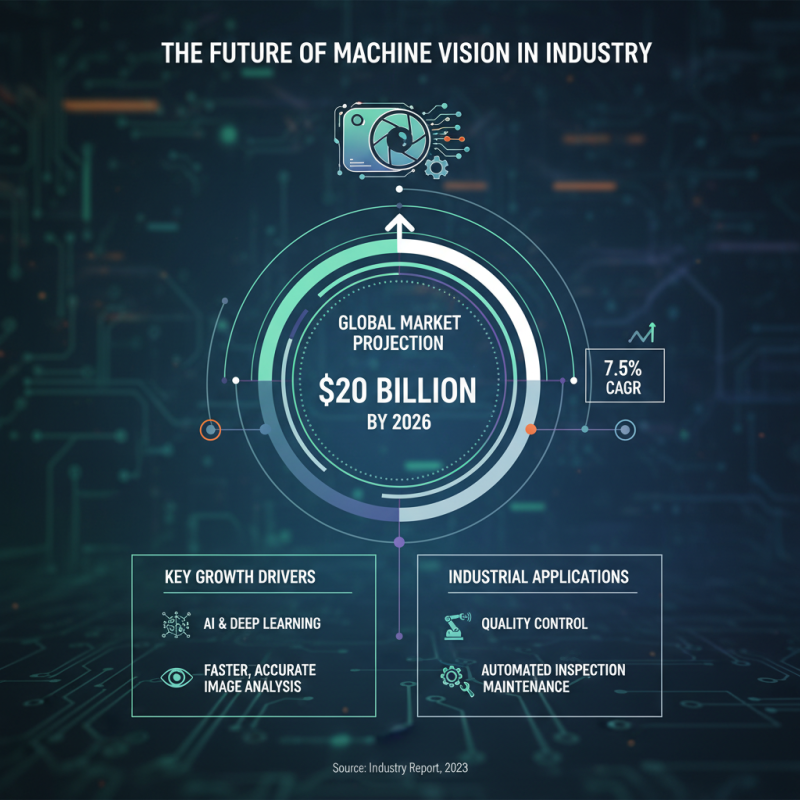

The future of machine vision technology in industrial applications looks promising. According to a recent industry report, the global machine vision market is projected to reach $20 billion by 2026, growing at a CAGR of 7.5%. This growth is driven by advancements in artificial intelligence and deep learning techniques, which allow for more accurate and faster image analysis.

One interesting trend is the integration of machine vision with robotics. By combining these technologies, industries can achieve more precise automation. This synergy can reduce production errors and improve inspection processes. However, businesses must be prepared for potential challenges, such as the initial costs of implementation and the need for skilled operators.

Tips: Consider starting with pilot projects before full-scale deployment. This approach can reduce risks and provide valuable insights. It allows for adjustments based on real-world performance. Also, invest in training for your team. Knowledge empowers employees to maximize the benefits of machine vision systems.

As new applications emerge, sensors and cameras are becoming more sophisticated. Companies must ensure that they select the right components. Customization may be necessary, depending on specific production needs. As this field evolves, staying updated on technology trends is essential for maintaining a competitive advantage.

Related Posts

-

Exploring the Future of Machine Vision Technologies in 2025 Top Applications

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries