Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

In the fast-paced world of industrial automation, the selection of the right components can significantly impact overall performance and efficiency. Among these components, the pneumatic control valve stands out as a crucial element in managing fluid control and pressure regulation within pneumatic systems. Designed to provide precision and reliability, pneumatic control valves play a vital role in a variety of applications, such as manufacturing processes to energy management. As industries strive for enhanced operational efficiency, understanding the best pneumatic control valves available on the market becomes essential.

In this article, we will explore the top seven pneumatic control valves that are anticipated to elevate industrial performance in 2025. By examining their features, benefits, and applications, we aim to provide insights that can help engineers and procurement professionals make informed decisions when selecting pneumatic control valves. Whether you're involved in system design, process optimization, or maintenance, this comprehensive guide will equip you with the knowledge needed to leverage the latest advancements in pneumatic control technology. Join us as we delve into the key characteristics that define the best pneumatic control valves and their potential to revolutionize industrial processes.

Types of Pneumatic Control Valves and Their Applications

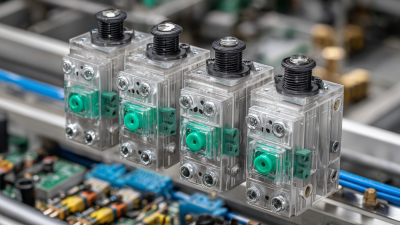

Pneumatic control valves are crucial components in various industrial applications, ensuring efficient operation and control of fluid flow. Among the primary types of pneumatic control valves are directional control valves, pressure control valves, and flow control valves.

Directional control valves manage the path through which air or fluid flows, essential for shifting operations in automated systems. Pressure control valves maintain the required pressure levels within a system, preventing overload and ensuring safety, while flow control valves regulate the speed and volume of fluid, optimizing performance.

In addition to their basic functions, these valves are also integrated into advanced systems such as digital closed-loop control strategies that enhance energy efficiency and responsiveness. The rise of such technologies is reflected in the increasing market demand for pneumatic components, with projections indicating substantial growth in the coming years. As industries continue to adopt automation and advanced control strategies, understanding the various types of pneumatic control valves and their specific applications will be vital for achieving enhanced performance and efficiency.

Key Features to Consider for Selecting Pneumatic Control Valves

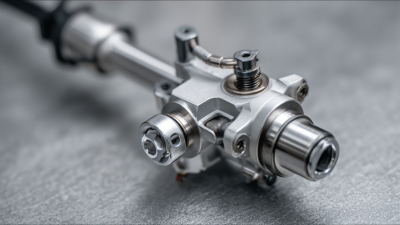

When selecting pneumatic control valves, several key features should be critically assessed to ensure optimal industrial performance. Firstly, the valve's ability to provide leak-tight performance at critical points such as connection, shutoff, and regulation is paramount. This is particularly important in applications like steam turbine governing systems where the reliability of governor valve actuators directly impacts production safety. Utilizing advanced design standards, such as those outlined in the ISA-75 series, can guide engineers in selecting valves that enhance safety, efficiency, and reliability.

Another critical aspect to consider is the responsiveness of the valve. Innovative control technologies, such as FOPID controllers, can optimize the performance of pneumatic control valves by ensuring rapid response times and minimal overshoot in pressure regulation. This not only aids in maintaining desired operational conditions but also enhances overall system robustness. As industries move towards more sophisticated automation, understanding these key features will contribute to better decision-making in valve selection, ultimately improving operational efficacy and system longevity.

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

| Model | Body Material | Pressure Range (bar) | Flow Coefficient (Cv) | Temperature Range (°C) | Control Type | Special Features |

|---|---|---|---|---|---|---|

| Model A | Aluminum | 1 - 10 | 3.5 | -10 to 80 | On/Off | Compact Design |

| Model B | Stainless Steel | 0.5 - 8 | 5.0 | -20 to 150 | Modulating | Corrosion Resistant |

| Model C | Brass | 0 - 12 | 4.0 | -10 to 100 | On/Off | Low Leakage |

| Model D | Composite Material | 1 - 5 | 3.0 | 0 to 80 | Modulating | Lightweight |

| Model E | Cast Iron | 2 - 10 | 7.0 | -30 to 120 | On/Off | Heavy Duty |

| Model F | Plastic | 0 - 3 | 1.5 | -10 to 80 | Modulating | Cost Effective |

| Model G | Nickel-Plated | 0 - 15 | 6.0 | -20 to 130 | On/Off | High Durability |

Comparison of Different Pneumatic Control Valve Designs

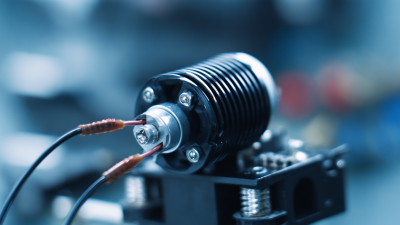

When evaluating pneumatic control valves, it is essential to understand the differences in design, as they can significantly impact industrial performance. Various designs exist to cater to specific applications, each offering unique advantages. Typically, pneumatic control valves come in two main configurations: direct-acting and pilot-operated. Direct-acting valves provide a simple and compact solution, ideal for low-flow applications, whereas pilot-operated valves are better suited for high-flow or high-pressure systems, offering enhanced control and responsiveness.

Another critical aspect of pneumatic control valve design is the actuator type. Spring-return actuators are popular for their reliability and simplicity, while double-acting actuators provide more control options, allowing for precise flow manipulation. The material choice also plays a pivotal role; for instance, valves made from corrosion-resistant materials are favored in harsh environments, ensuring a longer lifespan and decreased maintenance costs. Ultimately, understanding these design variations enables professionals to select the best pneumatic control valve that aligns with their operational needs, thereby improving overall industrial performance.

Benefits of Using Pneumatic Control Valves in Industrial Settings

Pneumatic control valves play a crucial role in enhancing industrial performance by providing precise control of air flow and pressure within a wide range of applications. According to a report by MarketsandMarkets, the global pneumatic valves market is projected to grow from USD 3.9 billion in 2021 to USD 5.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth underscores the increasing reliance on pneumatic systems in various sectors, including manufacturing, automotive, and pharmaceuticals, where efficiency and reliability are paramount.

The benefits of using pneumatic control valves are significant. They offer improved response times and reduced energy consumption when compared to traditional mechanical or electric control systems. Recent studies indicate that implementing pneumatic control systems can lead to a 20-30% reduction in overall energy costs in industrial plants. Furthermore, these valves are typically lighter and more compact than their counterparts, allowing for easier integration into existing systems and enhancing flexibility in design. Their ability to operate in extreme conditions—such as high temperatures and pressures—also makes them ideal for diverse industrial applications, ensuring robust performance and longevity.

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

Pneumatic control valves are essential components in industrial settings, enhancing performance and efficiency. This chart illustrates the performance ratings of seven different pneumatic control valves, indicating their effectiveness in various applications. Higher ratings signify better performance, which translates to improved operational reliability and cost savings in industrial processes.

Top Recommendations for Quality Pneumatic Control Valves in the Market

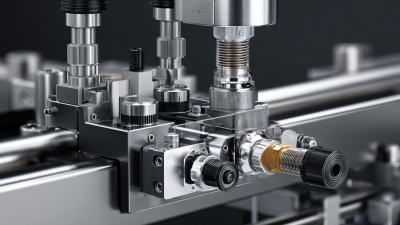

When it comes to optimizing industrial performance, selecting the right pneumatic control valve is crucial. Top recommendations for quality pneumatic control valves in the market highlight those that not only ensure efficient operation but also enhance the overall workflow. Look for valves that incorporate advanced technology, such as proportional control features, which allow for precise modulation of flow and pressure. Brands like Parker and SMC stand out for their reliability and innovative designs, catering to diverse industry needs.

Additionally, it's important to consider the material and construction of the valves. Valves made from corrosion-resistant materials provide longevity and reduced maintenance in harsh environments. Furthermore, balancing cost with performance is vital; investing in a premium valve can lead to greater savings long-term through reduced operational failures. By focusing on these key aspects, industries can elevate their performance and enhance their process control capabilities with the right pneumatic control valves.

Related Posts

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries