Top Benefits of Using Air Cylinders in Industrial Applications

Air cylinders, a vital component in many industrial applications, have garnered attention for their efficiency and reliability. These devices utilize compressed air to generate linear motion, making them essential in a variety of automated processes. Their versatility allows them to be employed in diverse sectors such as manufacturing, packaging, and material handling, where precision and speed are paramount. As industries continuously seek ways to enhance productivity and reduce operational costs, the adoption of air cylinders appears to be a strategic solution.

One of the key advantages of air cylinders is their simplicity in design, which contributes significantly to their ease of maintenance and operation. This straightforward mechanism not only minimizes downtime but also ensures consistent performance under various working conditions. Additionally, air cylinders provide a level of safety and control that is often unmatched by other types of actuators, making them a preferred choice for many industrial environments. As we delve deeper into the myriad benefits of using air cylinders, it becomes evident that their role in modern industry is vital for fostering innovation and efficiency.

Key Characteristics of Air Cylinders in Industrial Settings

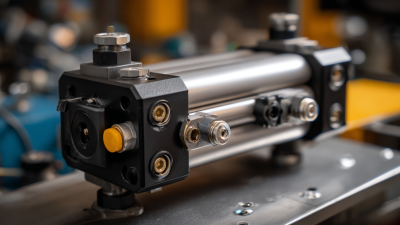

Air cylinders are essential components in industrial settings, known for their efficiency and reliability in powering various automated processes. One of the key characteristics of air cylinders is their simple design, which includes a cylinder body, piston, and rod. This simplicity not only facilitates easy installation and maintenance but also reduces potential points of failure, making air cylinders a preferred choice for many manufacturers. Additionally, their ability to generate linear motion from compressed air allows them to operate smoothly in applications ranging from packaging to assembly lines.

Another significant characteristic is the versatility of air cylinders. They can be adapted for use in various conditions, including extreme temperatures and harsh environments, thanks to the availability of different materials and sealing options. The speed and stroke length can also be customized, providing flexibility to meet specific operational needs. Moreover, air cylinders are capable of rapid actuation, making them ideal for high-speed operations where uptime is critical. Their reliability and performance make them indispensable tools in modern industrial applications, ensuring that processes run quickly and effectively while minimizing downtime.

Advantages of Air Cylinders over Other Actuation Systems

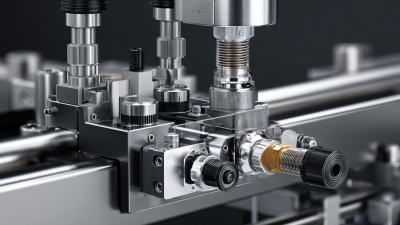

Air cylinders offer numerous advantages over other actuation systems, making them a preferred choice in various industrial applications. One of the primary benefits is their simplicity and reliability. Air cylinders operate using compressed air, which reduces the complexity of mechanical components and minimizes maintenance requirements. Unlike hydraulic systems that can suffer from leaks and require regular fluid changes, air cylinders are less prone to such issues, resulting in lower downtime and maintenance costs.

Another significant advantage of air cylinders is their speed and efficiency. These devices can achieve rapid actuation, allowing for quick movement and precise control in automation processes. This accelerated response time is particularly beneficial in high-speed production lines where time efficiency is crucial. Additionally, air cylinders provide consistent force output, enabling uniform performance throughout their cycle. This reliability in delivering consistent power is essential for achieving high-quality outcomes in manufacturing and assembly operations.

Furthermore, air cylinders are typically lighter than mechanical or hydraulic systems, facilitating easier integration into existing structures and machines. Their compact design allows for flexibility in tight spaces, making them suitable for a wide range of applications. The use of air as a power source also contributes to their eco-friendliness, as it minimizes the risk of environmental contamination associated with hydraulic fluids. Overall, the advantages of air cylinders over other actuation systems position them as a vital component in modern industrial operations.

Top Benefits of Using Air Cylinders in Industrial Applications

This chart illustrates the key benefits of using air cylinders in industrial applications. The data reflects the perceived advantages in various categories, with 'Speed of Operation' ranking highest, followed closely by 'Cost Efficiency' and 'Energy Efficiency'.

Applications of Air Cylinders in Various Industries

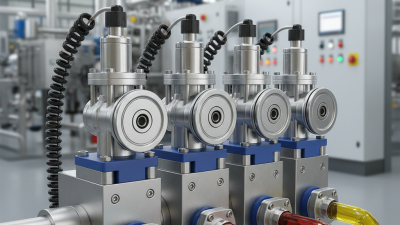

Air cylinders play a crucial role in a variety of industrial applications, providing reliable and efficient solutions for numerous tasks. In the manufacturing sector, air cylinders are widely used in material handling systems to automate the movement of goods. Their ability to generate linear motion with precision allows them to operate conveyor belts, lift and lower items, and assist in assembly processes, ultimately boosting productivity and reducing manual labor.

In the automotive industry, air cylinders are essential for automating production lines. They are employed in tasks such as welding, painting, and component assembly, where speed and accuracy are vital. Additionally, air cylinders are utilized in packaging machinery for sealing boxes and packing products efficiently. The versatility of air cylinders also extends to the food and beverage industry, where they assist in packaging, bottling, and palletizing processes, ensuring hygiene and operational efficiency while adhering to industry safety standards.

Top Benefits of Using Air Cylinders in Industrial Applications

| Industry | Application | Key Benefit | Efficiency Improvement (%) |

|---|---|---|---|

| Manufacturing | Material Handling | Increased Speed | 25% |

| Automotive | Assembly Line Automation | Reduced Downtime | 30% |

| Pharmaceutical | Packaging | Improved Precision | 20% |

| Food & Beverage | Filling Processes | Enhanced Safety | 15% |

| Construction | Material Placement | Increased Load Handling | 35% |

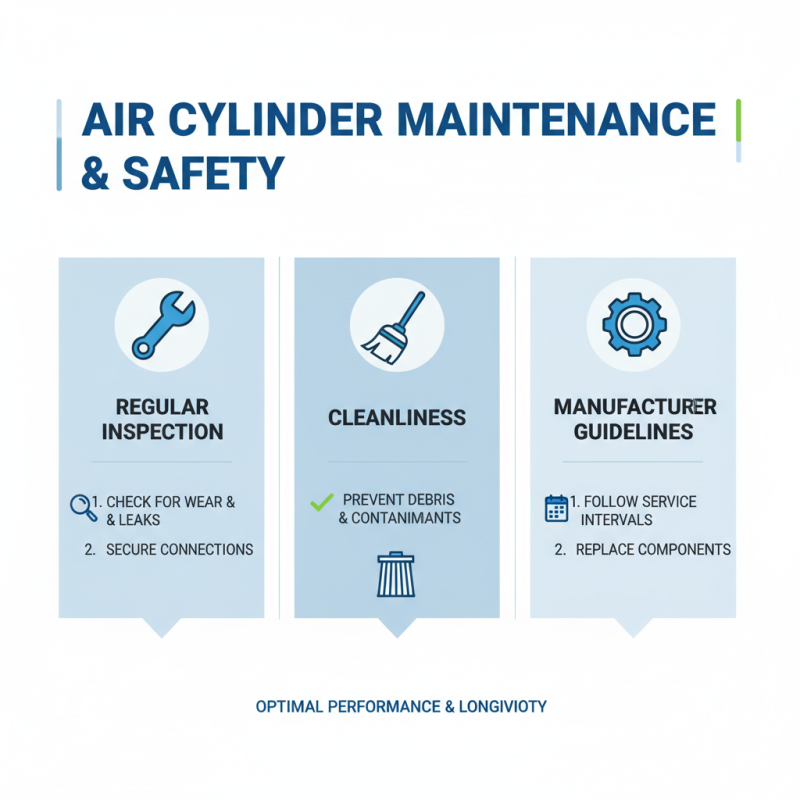

Maintenance and Safety Considerations for Air Cylinders

When utilizing air cylinders in industrial applications, maintenance and safety considerations play a crucial role in ensuring optimal performance and longevity. Regular inspection of air cylinders is essential; this includes checking for any signs of wear, leaks, and ensuring that all connections are secure. Keeping the cylinder and its components clean from debris and contaminants can prevent malfunctioning and increase efficiency. Additionally, it’s important to follow the manufacturer’s guidelines for service intervals and component replacement to mitigate the risk of unexpected failures.

Safety protocols must also be taken into account to protect workers and equipment. Operators should be trained on the safe use of air cylinders, including proper handling techniques and awareness of potential hazards. Implementing safety measures such as pressure relief valves and automatic shut-off systems can help avert accidents caused by over-pressurization. Moreover, establishing a regular maintenance schedule not only enhances safety but also promotes a culture of responsibility among workers, ensuring that they remain vigilant about the condition of the equipment. This holistic approach to maintenance and safety will ultimately contribute to a safer and more efficient working environment.

Future Trends in Air Cylinder Technology and Usage

As we look towards the future, air cylinder technology is set to undergo significant transformations driven by advancements in materials science, automation, and sustainability. According to a recent report by MarketsandMarkets, the global pneumatic cylinder market is expected to exceed $17 billion by 2026, reflecting a compound annual growth rate (CAGR) of over 5.5% from 2021. This growth is fueled by increasing demands for automation in manufacturing processes, where air cylinders play a pivotal role in enhancing efficiency and reliability.

Moreover, the integration of Internet of Things (IoT) technology into air cylinder systems is a rising trend that promises to revolutionize their usage. Industry analysts project that by 2025, more than 30% of pneumatic actuators will be equipped with IoT capabilities, allowing for real-time monitoring and predictive maintenance. Such innovations not only improve operational efficiency but also extend the lifespan of air cylinders, reducing downtime and maintenance costs for manufacturers. As companies continue to prioritize sustainability, the adoption of eco-friendly materials and energy-efficient designs in air cylinder production is also expected to rise, aligning with global efforts to reduce industrial carbon footprints.

Related Posts

-

How to Choose the Right Air Cylinder for Your Application

-

How to Choose the Right Pneumatic Air Cylinder for Your Application

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries